Description

GE IS200VRTDH1D RTD Input Module

Product Overview

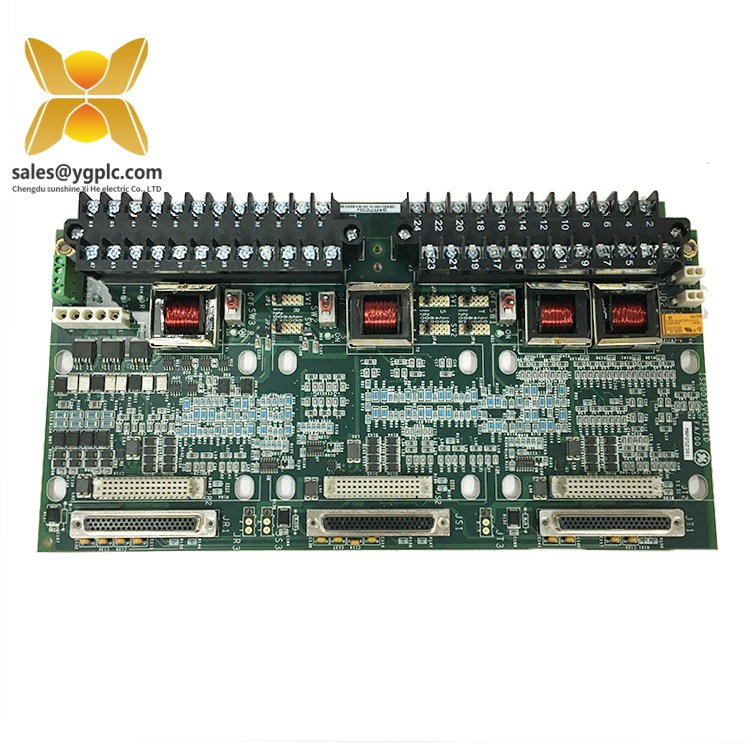

The GE IS200VRTDH1D is a high-precision RTD Input Module designed for industrial temperature monitoring within GE’s Mark VIe Distributed Control System (DCS), catering to critical applications in power generation, oil & gas, and manufacturing. Engineered to convert resistance temperature detector (RTD) signals into digital data, this module ensures accurate temperature measurement for process control and machinery protection. As part of the IS200 Series, the IS200VRTDH1D integrates seamlessly with other Mark VIe components (e.g., CPU modules, communication gateways), forming a robust ecosystem for real-time temperature analysis in harsh industrial environments.

Featuring a rugged industrial design, the GE IS200VRTDH1D supports multiple RTD types (e.g., Pt100, Ni100) and accommodates 8 isolated input channels, each capable of handling 2-wire, 3-wire, or 4-wire configurations. Its advanced signal conditioning circuitry includes linearization and cold-junction compensation, ensuring measurement accuracy within ±0.1% of full scale. The module’s hot-swappable design allows replacement without system shutdown, minimizing downtime during maintenance, while its wide operating temperature range (-40°C to +85°C) ensures reliable performance in extreme conditions. Compatibility with GE’s Proficy software enables intuitive configuration and real-time data visualization, enhancing operational efficiency.

In automation systems, the IS200VRTDH1D serves as the interface between field RTD sensors and the Mark VIe control platform, facilitating seamless integration with PLCs, SCADA systems, and HMIs. Its built-in diagnostic features monitor sensor health and signal integrity, providing real-time alerts for open circuits, short circuits, or out-of-range conditions. By delivering precise temperature data for turbine control, process optimization, and safety interlocks, this module supports predictive maintenance strategies and reduces the risk of equipment failure in mission-critical operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200VRTDH1D |

| Manufacturer | GE |

| Product Type | RTD Input Module |

| Platform | Mark VIe DCS |

| Input Channels | 8 isolated channels |

| RTD Types | Pt100, Ni100, Ni120, Cu50, Cu100 |

| Wiring Configuration | 2-wire, 3-wire, 4-wire |

| Measurement Range | -200°C to +650°C (Pt100) |

| Accuracy | ±0.1% of full scale |

| Resolution | 16-bit |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted in Mark VIe enclosure |

| Communication | Proprietary Mark VIe bus (compatible with Modbus via gateway) |

Key Features and Advantages

High-Precision Temperature Sensing: The IS200VRTDH1D delivers accurate temperature measurements with ±0.1% accuracy, enabling precise process control and early detection of thermal anomalies in critical equipment like turbines and reactors.

Multi-Type RTD Compatibility: Supporting various RTD sensors, the module adapts to diverse industrial setups, reducing the need for specialized hardware and simplifying inventory management. Its configurable wiring options (2/3/4-wire) accommodate different installation requirements.

Robust Diagnostic Capabilities: Built-in self-test functions monitor sensor connectivity and signal quality, flagging faults such as open circuits or excessive noise. This proactive diagnostics reduces troubleshooting time and enhances system availability.

Hot-Swap Functionality: The module can be replaced without powering down the system, allowing maintenance during operation. This feature is critical for 24/7 industrial processes where downtime is costly.

Wide Environmental Tolerance: Engineered to withstand extreme temperatures and harsh conditions, the IS200VRTDH1D ensures reliable performance in refineries, power plants, and other challenging environments.

Seamless System Integration: Compatible with GE’s Mark VIe DCS and Proficy software, the module supports real-time data integration with enterprise systems, enabling remote monitoring and data-driven decision-making.

Application Areas

The GE IS200VRTDH1D is essential for temperature monitoring in industries requiring precise thermal management:

- Power Generation: Monitors stator and rotor temperatures in generators, steam turbines, and transformers to prevent overheating and optimize energy efficiency.

- Oil & Gas: Measures process temperatures in refineries, pipelines, and offshore platforms, supporting safe operation and regulatory compliance.

- Chemical Processing: Controls reactor temperatures in petrochemical plants, ensuring optimal reaction conditions and preventing hazardous overreactions.

- Manufacturing: Monitors oven and furnace temperatures in automotive, pharmaceutical, and food processing facilities to maintain product quality and consistency.

- Water/Wastewater Treatment: Measures fluid temperatures in treatment plants to optimize chemical dosing and biological process efficiency.

Specific applications include:

- Turbine Health Monitoring: Integrates with RTDs on turbine casings and bearings to detect overheating, enabling proactive maintenance.

- Process Heating Control: Regulates heater temperatures in distillation columns and heat exchangers for efficient material processing.

- Environmental Monitoring: Measures ambient temperatures in storage facilities to protect sensitive materials from thermal stress.

Related Products

- IS200VPDCH1B (Power Distribution Module): Supplies redundant power to the IS200VRTDH1D and other Mark VIe modules, ensuring uninterrupted operation.

- IS200TBCHH1B (Terminal Block Module): Simplifies field wiring for the IS200VRTDH1D, providing a centralized connection point for RTD sensors.

- IS200CPUCH1A (CPU Module): Processes temperature data from the IS200VRTDH1D for control logic execution in Mark VIe systems.

- IS200COMMH1A (Communication Module): Enables Ethernet connectivity for the IS200VRTDH1D, supporting remote data access via SCADA systems.

- IS200ALGCH1A (Algorithm Module): Executes advanced control algorithms using temperature data from the IS200VRTDH1D for complex process optimization.

- IS200DCHHH1B (Digital Output Module): Triggers alarms or control actions based on temperature thresholds measured by the IS200VRTDH1D.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE IS200VRTDH1D, ensure the Mark VIe rack is properly grounded and ventilated. Verify RTD sensor compatibility and wiring configuration (2/3/4-wire). Use shielded cables to connect RTDs to the module’s terminal block, routing them away from high-voltage lines to minimize interference. Configure the module in GE’s Proficy software, assigning channel addresses and selecting RTD types for each input. Mount the module in the rack using anti-vibration brackets, ensuring adequate spacing for heat dissipation.

Before installing the GE IS200VRTDH1D, ensure the Mark VIe rack is properly grounded and ventilated. Verify RTD sensor compatibility and wiring configuration (2/3/4-wire). Use shielded cables to connect RTDs to the module’s terminal block, routing them away from high-voltage lines to minimize interference. Configure the module in GE’s Proficy software, assigning channel addresses and selecting RTD types for each input. Mount the module in the rack using anti-vibration brackets, ensuring adequate spacing for heat dissipation.

Maintenance Suggestions:

- Routine Checks: Monthly visual inspections of terminal connections and LED indicators to ensure secure wiring and normal operation. Use Proficy software to review channel diagnostics for out-of-range readings or fault codes.

- Calibration: Annually calibrate the IS200VRTDH1D using a precision temperature source to verify measurement accuracy. Compare module readings against reference standards and adjust as needed.

- Environmental Management: Quarterly cleaning of the module’s vents to prevent dust accumulation, especially in dusty environments. Ensure the control room maintains stable temperature and humidity levels.

- Spare Parts Management: Store spare IS200VRTDH1D modules in a static-controlled environment (20–25°C, <50% humidity) and test them periodically to ensure functionality.

Product Guarantee

Our company provides a 12-month quality warranty for the GE IS200VRTDH1D, covering hardware defects under normal use. In the event of measurement inaccuracies or functional failures, we offer prompt replacement services to minimize downtime. For legacy or urgent requirements, our global supply chain ensures rapid delivery of the IS200VRTDH1D and related spares. Our technical support team assists with installation, calibration, and troubleshooting, delivering reliable solutions to maintain your temperature monitoring systems.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IS200SDIIH1ADB MRP683026 | Mark VIe Digital Input Module | IS200TBCIH1BBC

GE IS200STAOH2AAA | Synchronizer Module (Gas Turbine Control) | IS200SPIDG1ABA

GE IS200STCIH2A | Turbine Control Interface Module | IS200PMCIH1ABA

GE IS200TBAIH1CCC | Mark VIe Terminal Block Interface Module | IS200SRTDH2ACB

GE IS200TBCIH1BBC | Contact Terminal Board, Mark VIe Series | IS200TDBSH2ACC

GE IS200TDBTH6ACD | Terminal Board Module | IS200TVIBH2BBB

GE IS200ISBBG2AAB | Interface Module (Turbine Control) | IS200PMCIH1ABA

GE IS200EROCH1ABB | Exciter Regulator Output Module | IS200JPDDG1AAA

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: