Description

GE IS200VCMIH2CAA Product Specification

Product Overview

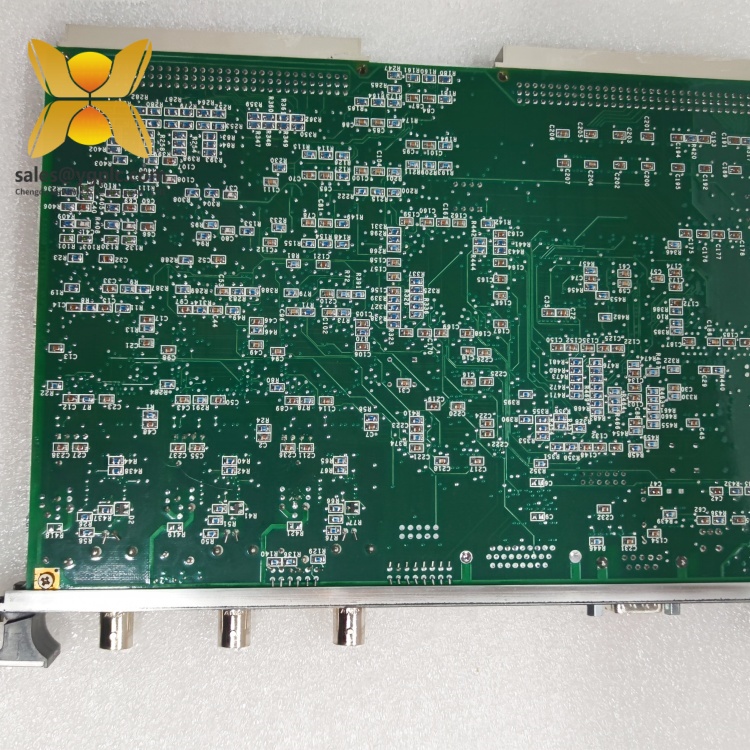

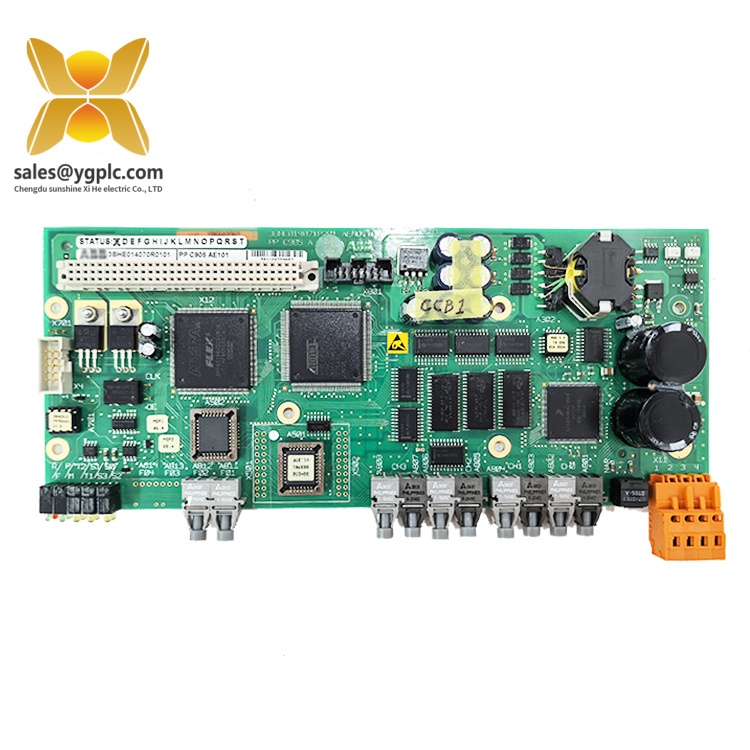

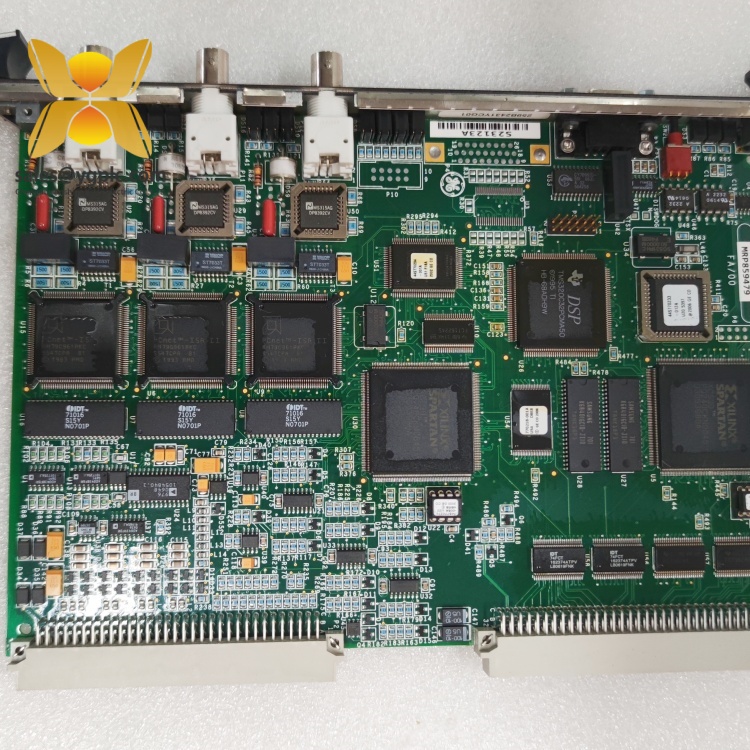

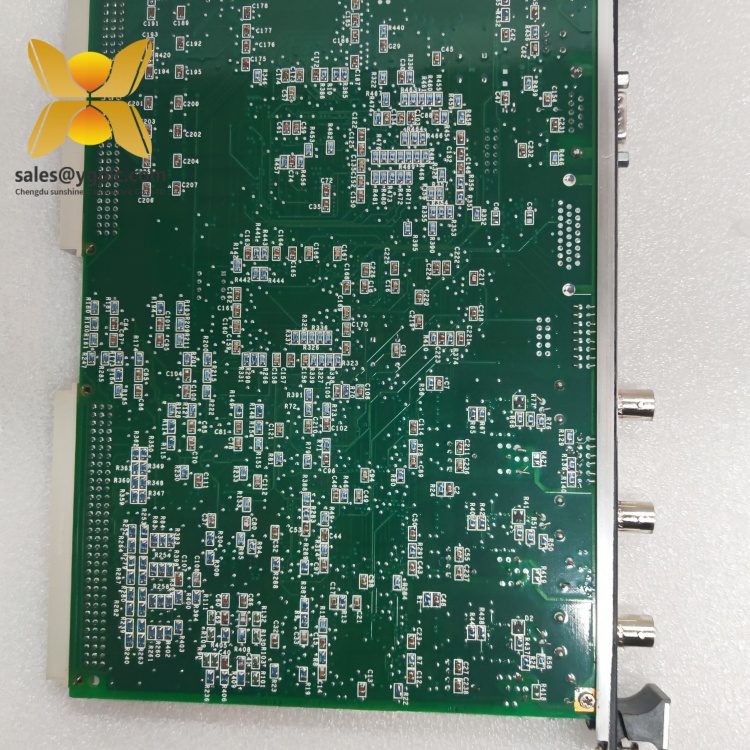

The GE IS200VCMIH2CAA is a VME Bus Master Communication Controller Board designed for GE’s Mark VI Speedtronic Turbine Control System, a cornerstone of industrial automation in power generation, oil and gas, and heavy machinery. As the central communication hub of Mark VI architectures, this module enables seamless data exchange between the CPU, I/O cards, and external devices, ensuring precise coordination of gas/steam turbine operations. Engineered with rugged hardware and advanced processing capabilities, the IS200VCMIH2CAA thrives in harsh environments, from offshore platforms to thermal power plants, where reliability and real-time performance are critical.

Featuring a Texas Instruments TMS320C32 32-bit digital signal processor and 32 KB dual-port memory, the IS200VCMIH2CAA executes complex control algorithms with deterministic precision. Its front panel includes three IONET connectors, a 9-pin serial port, and status LEDs (Run, Fail, Status) for real-time health monitoring. The board’s conformal-coated PCB and metal enclosure protect against dust, moisture, and electromagnetic interference (EMI), while a rugged design withstands vibration (75 G peak) and shock. Operating within a 0–60°C temperature range (with extended variants available), it ensures consistent performance in demanding industrial settings.

In automation systems, the IS200VCMIH2CAA acts as the backbone of Mark VI configurations, managing data flow between critical components like turbine speed sensors, fuel valves, and safety interlocks. Its dual backplane connectors enable integration with terminal boards (e.g., IS200TBCHH1AAA), while support for protocols like IONET and serial communication ensures compatibility with legacy and modern devices. The module’s role is pivotal in maintaining system synchronization, enabling precise control over turbine start-up sequences, load balancing, and emergency shutdowns.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200VCMIH2CAA |

| Manufacturer | General Electric (GE) |

| Product Type | VME Bus Master Communication Controller Board |

| Series | Mark VI Speedtronic Turbine Control System |

| Processor | Texas Instruments TMS320C32 (32-bit DSP) |

| Memory | 32 KB dual-port SRAM |

| Communication Interfaces | 3 × IONET ports, 1 × RS-232 (9-pin male) |

| Power Supply | +5 VDC (6 A typical, 8 A max) |

| Physical Dimensions | 168 mm (H) × 150 mm (W) × 55 mm (D) |

| Weight | 2 kg (4.4 lbs) |

| Operating Temperature | 0–60°C (extended variants: -40–70°C) |

| Humidity | 5–95% non-condensing |

| Mounting | VME 64x rack (3U form factor, slot 1) |

| Certifications | CE, UL, ISO 16132 |

Main Features and Advantages

Deterministic Communication Hub:

The IS200VCMIH2CAA serves as the primary interface for data exchange within Mark VI systems, ensuring sub-millisecond response times for critical control signals. Its IONET ports enable high-speed synchronization with I/O modules (e.g., IS200TBCBH1AAA), while the RS-232 port supports legacy device integration. This architecture minimizes latency in turbine speed regulation and load-sharing applications, enhancing overall system stability.

The IS200VCMIH2CAA serves as the primary interface for data exchange within Mark VI systems, ensuring sub-millisecond response times for critical control signals. Its IONET ports enable high-speed synchronization with I/O modules (e.g., IS200TBCBH1AAA), while the RS-232 port supports legacy device integration. This architecture minimizes latency in turbine speed regulation and load-sharing applications, enhancing overall system stability.

Rugged Industrial Design:

The module’s triple-layer conformal coating and metal enclosure protect against environmental hazards, making it suitable for offshore platforms, refineries, and other harsh environments. Hot-swappable design allows maintenance without system shutdowns, reducing mean time to repair (MTTR) and downtime costs. The board’s robust construction also ensures compliance with EMI/EMC standards, critical for maintaining signal integrity in high-noise environments.

The module’s triple-layer conformal coating and metal enclosure protect against environmental hazards, making it suitable for offshore platforms, refineries, and other harsh environments. Hot-swappable design allows maintenance without system shutdowns, reducing mean time to repair (MTTR) and downtime costs. The board’s robust construction also ensures compliance with EMI/EMC standards, critical for maintaining signal integrity in high-noise environments.

Comprehensive Diagnostics:

Front-panel LEDs and built-in self-tests continuously monitor voltage levels, thermal stress, and communication health. Faults are logged with timestamped records, enabling rapid post-event analysis and predictive maintenance. This proactive approach helps identify potential issues—such as failing connectors or overheating—before they escalate into system-wide failures.

Front-panel LEDs and built-in self-tests continuously monitor voltage levels, thermal stress, and communication health. Faults are logged with timestamped records, enabling rapid post-event analysis and predictive maintenance. This proactive approach helps identify potential issues—such as failing connectors or overheating—before they escalate into system-wide failures.

Flexible Configuration:

The IS200VCMIH2CAA supports configurable IONET addresses and baud rates, allowing seamless integration into simplex or redundant Mark VI setups. Its dual-port memory facilitates concurrent data access by the CPU and I/O modules, optimizing multitasking in complex control scenarios. Additionally, the board’s firmware is field-upgradable via GE’s Proficy software, ensuring compatibility with future system enhancements.

The IS200VCMIH2CAA supports configurable IONET addresses and baud rates, allowing seamless integration into simplex or redundant Mark VI setups. Its dual-port memory facilitates concurrent data access by the CPU and I/O modules, optimizing multitasking in complex control scenarios. Additionally, the board’s firmware is field-upgradable via GE’s Proficy software, ensuring compatibility with future system enhancements.

Application Areas

-

Power Generation:

- Steam/Gas Turbine Control: Manages turbine governor systems to maintain grid frequency (50/60 Hz) and voltage stability during start-up, load changes, and synchronization with the power grid.

- Emergency Shutdown Systems: Integrates with safety interlocks to execute rapid shutdown sequences in response to equipment malfunctions or abnormal operating conditions.

- Combined Cycle Plants: Coordinates operations between gas and steam turbines, optimizing energy efficiency and reducing emissions.

-

Oil and Gas:

- Pipeline Compression: Regulates compressor motor speeds in refineries and pipeline pumping stations, preventing overpressure and thermal overload.

- Offshore Platforms: Ensures reliable communication in corrosive, high-vibration environments, critical for monitoring wellhead operations and LNG processing.

-

Industrial Manufacturing:

- Process Automation: Controls high-speed conveyor systems, robotic arms, and precision machinery in automotive and pharmaceutical plants, ensuring synchronized operation.

- Steam Turbine-Driven Pumps: Manages steam-driven pumps in chemical processing facilities to maintain consistent fluid flow rates and pressure.

-

Water/Wastewater Treatment:

- Pump Motor Control: Optimizes pump speeds in water treatment plants for efficient filtration and chemical dosing, reducing energy consumption.

- Aeration Systems: Monitors and adjusts aeration rates in wastewater facilities to support biological treatment processes and regulatory compliance.

Related Products

- GE IS200VCMIH2C: Simplex/TMR (Triple Modular Redundancy) variant with three IONET ports, offering enhanced fault tolerance for safety-critical applications.

- GE IS200VCMIH2BCB: Alternative version with revised circuitry for specific Mark VI system configurations.

- GE IS200VSCAH2AAA: VME Serial Community Attachment module for extended RS-232/485 connectivity, often paired with IS200VCMIH2CAA for multi-protocol integration.

- GE IS200TBCBH1AAA: Digital Input/Output module for field signal conditioning, directly interfacing with the IS200VCMIH2CAA via IONET.

- GE IS200VMEBH1A: VME backplane module providing mechanical and electrical support for Mark VI rack systems, ensuring stable power and signal routing.

- GE IS215VCMIH2BB: Upgraded communication board for Mark VIe systems, featuring higher processing power and Ethernet connectivity.

Installation and Maintenance

Pre-installation Preparation:

- Environmental Checks: Verify ambient temperature (0–60°C) and humidity (5–95% non-condensing) to ensure compatibility. Use an anti-static wrist strap and grounded workbench to prevent ESD damage during handling.

- Rack Configuration: Install the IS200VCMIH2CAA in the first slot of a Mark VI VME rack, securing it with anti-vibration brackets. Ensure proper grounding of the rack to comply with EMI/EMC standards.

- Cabling: Connect IONET cables to the front-panel connectors and terminal boards (e.g., IS200TBCHH1AAA) for field signal integration. Confirm all connections are secure and labeled for easy identification.

- Software Setup: Use GE’s Proficy Machine Edition to configure IONET addresses, baud rates, and communication protocols. Load the latest firmware to ensure compatibility with existing system components.

Maintenance Recommendations:

- Monthly Inspections: Visually check front-panel LEDs (green = normal operation, red = fault) and clean dust from ventilation slots using compressed air. Inspect cable connectors for corrosion or loose connections.

- Annual Calibration: Use a certified signal generator to verify analog I/O accuracy (±0.5% of full scale) and communication integrity. Replace any degraded cables or terminal blocks.

- Firmware Updates: Periodically update the module’s firmware via Proficy to access bug fixes, security patches, and compatibility enhancements. Document all changes for traceability.

- Thermal Management: Replace CPU thermal compound every 2–3 years to maintain optimal heat dissipation. Monitor operating temperatures using Proficy’s diagnostic tools to detect abnormal hotspots.

Product Warranty

Our company provides a one-year quality warranty for the GE IS200VCMIH2CAA, covering hardware defects unrelated to misuse or environmental damage. During the warranty period, we offer free replacement for modules exhibiting abnormal performance or functional failures. For discontinued models or urgent requirements, our global inventory and supply chain network ensure rapid delivery of scarce spare parts within 24–48 hours. Post-warranty, our certified technicians provide repair services and technical support, including remote diagnostics and compatibility assessments, to sustain your critical systems’ reliability.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document synthesizes third-party technical resources and industry applications. For detailed installation guides or compliance documentation, refer to GE’s Mark VI Speedtronic System Manual or contact our technical support team.

GE IC754CSL12CTD Safety system

GE IC800SSI216RD2-CE Distributed control

GE IC800SSI228RD2-CE Terminal panel

GE IC800SSI228RD2-EE PDP panel

GE IC660BBD110 Safety system

GE IC660EBD020 Distributed control

GE SR469 469-P5-HI-A20-E redundancy

GE IS220PDIAH1A Network communication

GE CK11CE300 Safety system

GE IC695CPE400-ABAB Distributed control

GE IS420UCSBH3A Terminal panel

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: