Description

GE IS200TSVCH1AJE Product Specification

Product Overview

The GE IS200TSVCH1AJE is a high-reliability turbine speed and vibration control module engineered for GE’s Mark VIe Turbine Control System, a cornerstone of industrial automation in power generation and heavy machinery applications. As part of the IS200 series, this module serves as a critical component for monitoring and regulating turbine operations, ensuring precise control over rotational speed, vibration parameters, and emergency shutdown sequences. The GE IS200TSVCH1AJE integrates advanced signal processing with rugged industrial design, making it essential for industries such as power generation, oil and gas, and manufacturing that demand uninterrupted turbine performance.

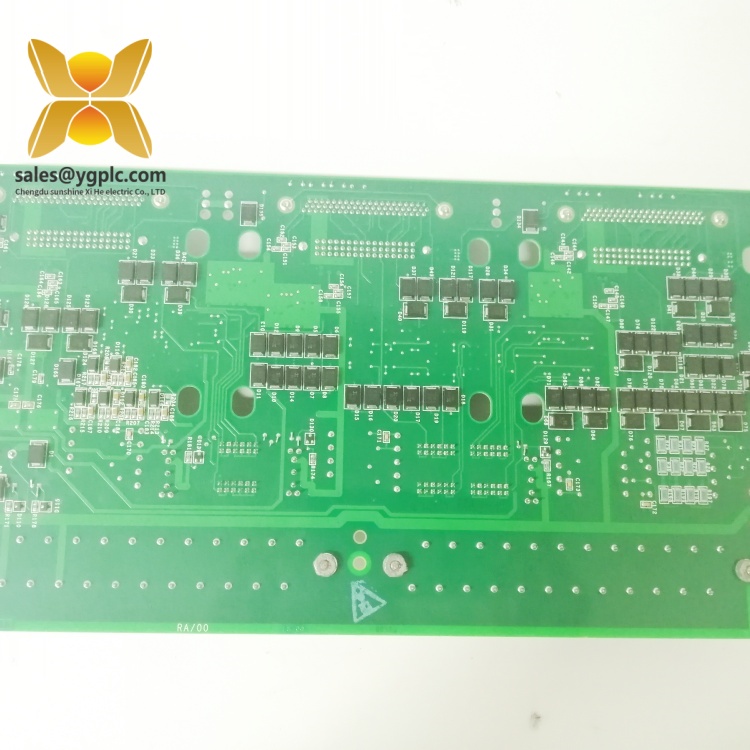

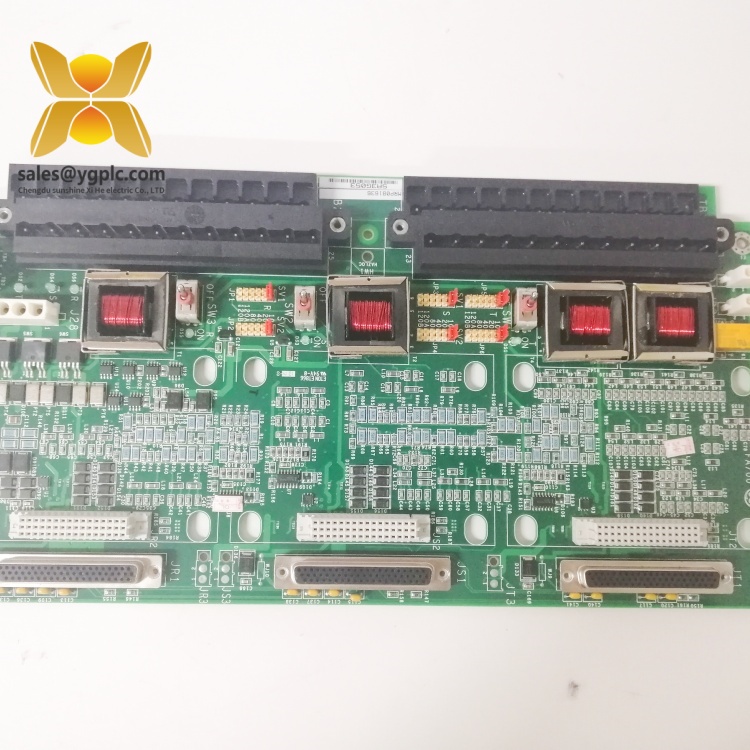

Designed to interface with proximity probes, accelerometers, and tachometers, the GE IS200TSVCH1AJE processes up to 8 channels of analog and digital inputs, converting them into real-time control signals for turbine governors and protection systems. Its 32-bit microprocessor and 16 MB of flash memory enable high-speed data processing and storage, while the module’s hot-swappable design allows maintenance without system shutdowns. With a compact form factor (200 mm × 150 mm × 100 mm) and IP23-rated enclosure, the GE IS200TSVCH1AJE withstands harsh environments, including high temperatures and vibration, typical of turbine installations.

In automation systems, the GE IS200TSVCH1AJE acts as a central hub for turbine health monitoring, combining speed regulation with vibration analysis to prevent catastrophic failures. Its support for Modbus and Ethernet/IP protocols ensures seamless integration with SCADA systems, enabling remote diagnostics and predictive maintenance. By delivering precise control and real-time diagnostics, the module enhances operational efficiency, reduces downtime, and extends turbine lifespan in mission-critical applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200TSVCH1AJE |

| Manufacturer | General Electric (GE) |

| Product Type | Turbine Speed and Vibration Control Module |

| Input Channels | 8 channels (4 speed, 4 vibration) |

| Input Signal Types | 4–20 mA, 0–10 VDC, TTL/CMOS |

| Communication Protocols | Modbus RTU, Ethernet/IP |

| Power Supply | 24 VDC ±10% |

| Physical Dimensions | 200 mm (W) × 150 mm (H) × 100 mm (D) |

| Weight | 1.8 kg |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, ISO 9001 |

Main Features and Advantages

Dual-Function Monitoring: The GE IS200TSVCH1AJE combines speed and vibration monitoring in a single module, eliminating the need for separate units and reducing rack space requirements. This integration enables comprehensive turbine health analysis, detecting imbalances or speed fluctuations before they escalate into failures.

High-Speed Processing: With a 32-bit microprocessor and 16 MB memory, the module processes up to 10 kHz signals, ensuring real-time response to dynamic turbine conditions. This capability is critical for maintaining grid stability in power generation applications.

Redundant Communication: Support for both Modbus and Ethernet/IP protocols allows redundant network configurations, ensuring continuous data transmission in critical systems. The dual communication paths enhance system reliability and facilitate integration with legacy and modern control architectures.

Rugged Industrial Design: The IP23-rated enclosure and conformal-coated PCBs protect the GE IS200TSVCH1AJE against dust, moisture, and electromagnetic interference (EMI). Its wide temperature range makes it suitable for harsh environments, including gas turbine installations in desert or offshore locations.

Hot-Swap Capability: The module’s hot-swappable design enables replacement without powering down the turbine control system, minimizing maintenance downtime. This feature is invaluable in 24/7 operations where system availability is non-negotiable.

Application Areas

The GE IS200TSVCH1AJE is pivotal in industries relying on turbine-driven systems:

-

Power Generation:

- Monitors steam turbine speed and vibration in thermal power plants, ensuring grid synchronization and optimal energy production.

- Integrates with gas turbines in combined cycle plants, adjusting fuel supply to maintain speed stability during load fluctuations.

-

Oil and Gas:

- Controls compressor turbines in refineries and pipeline pumping stations, preventing over-speed conditions that could lead to equipment damage.

- Monitors vibration in offshore platform turbines, enabling early detection of bearing wear or misalignment in harsh marine environments.

-

Manufacturing:

- Regulates steam turbine speed in paper mills and chemical plants, maintaining process consistency in high-volume production.

- Supports emergency shutdown systems in manufacturing facilities, ensuring safe shutdowns in the event of abnormal vibration levels.

-

Marine Propulsion:

- Controls marine turbine speed for ship propulsion systems, adapting to varying load conditions during navigation.

- Monitors vibration in onboard power generation turbines, supporting reliable operation in maritime environments.

Related Products

- GE IS200TCCVH1AAA: A turbine control core module that works in tandem with the GE IS200TSVCH1AJE to manage overall turbine operation.

- GE IS200TSSCH1AAE: A speed sensor interface module compatible with the GE IS200TSVCH1AJE, enhancing speed monitoring capabilities.

- GE IS200TVIBH1AGA: A dedicated vibration monitoring module for expanded channel requirements, often used alongside the GE IS200TSVCH1AJE in complex setups.

- GE IS200TBCCH1BBA: A bus communication module that facilitates data exchange between the GE IS200TSVCH1AJE and other Mark VIe components.

- GE IS200TPWXH1BAA: A power supply module providing stable 24 VDC to the GE IS200TSVCH1AJE and other Mark VIe modules.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IS200TSVCH1AJE, ensure the following:

Before installing the GE IS200TSVCH1AJE, ensure the following:

- Verify the power supply meets 24 VDC ±10% and that the control rack is properly grounded to prevent electrostatic discharge (ESD). Use a multimeter to confirm voltage stability.

- Configure input channels via GE’s Proficy software, defining speed and vibration sensor types (e.g., proximity probes, accelerometers) and setting alarm thresholds based on turbine specifications.

- Mount the module in a 19″ rack with at least 50 mm of clearance for airflow, securing it with anti-vibration brackets to minimize mechanical stress.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks of front-panel LEDs (green for normal operation, red for faults) and cleaning dust from ventilation slots using a soft brush.

- Calibration: Annual calibration of input channels using certified test equipment to ensure speed and vibration measurement accuracy.

- Firmware Updates: Periodically update the module’s firmware via GE’s diagnostic tools to access new features and compatibility with newer Mark VIe systems.

- Redundancy Testing: Biannual functional tests of communication protocols and hot-swap capability to ensure system reliability during maintenance events.

Product Warranty

Our company provides a one-year quality warranty for the GE IS200TSVCH1AJE, covering hardware failures due to non-human factors. During the warranty period, we will replace any module that exhibits abnormal signal processing or functional defects. For discontinued models like the GE IS200TSVCH1AJE, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support and repair services, leveraging our 17-year expertise in industrial control distribution to maintain your system’s reliability.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data from GE’s official specifications and industry applications. For detailed operation guidelines, refer to the GE IS200TSVCH1AJE user manual or contact our technical support team.

GE IS200SAMBH1ABA | Sensor Interface Module for Mark VIe Turbine Control System | IS200STCIH2A

GE IS200SDIIH1ADB MRP683026 | Mark VIe Digital Input Module | IS200TBCIH1BBC

GE IS200STAOH2AAA | Synchronizer Module (Gas Turbine Control) | IS200SPIDG1ABA

GE IS200STCIH2A | Turbine Control Interface Module | IS200PMCIH1ABA

GE IS200TBAIH1CCC | Mark VIe Terminal Block Interface Module | IS200SRTDH2ACB

GE IS200TBCIH1BBC | Contact Terminal Board, Mark VIe Series | IS200TDBSH2ACC

GE IS200TBCIH2CAA | Terminal Block Interface Module | IS200TBCIS2CCD

GE IS200TBCIS2CCD | Mark VIe Terminal Block Interface Module | IS200TDBTH6ACD

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: