Description

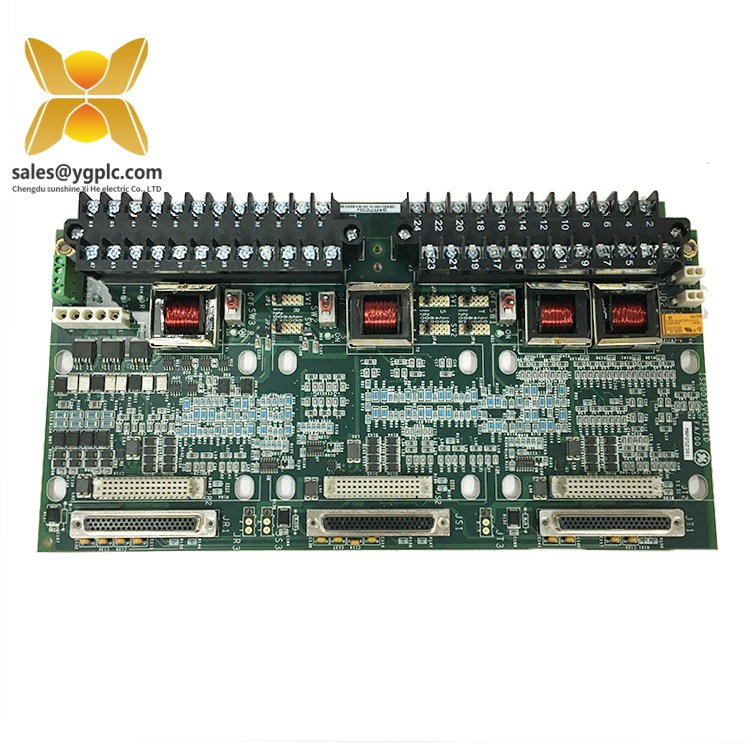

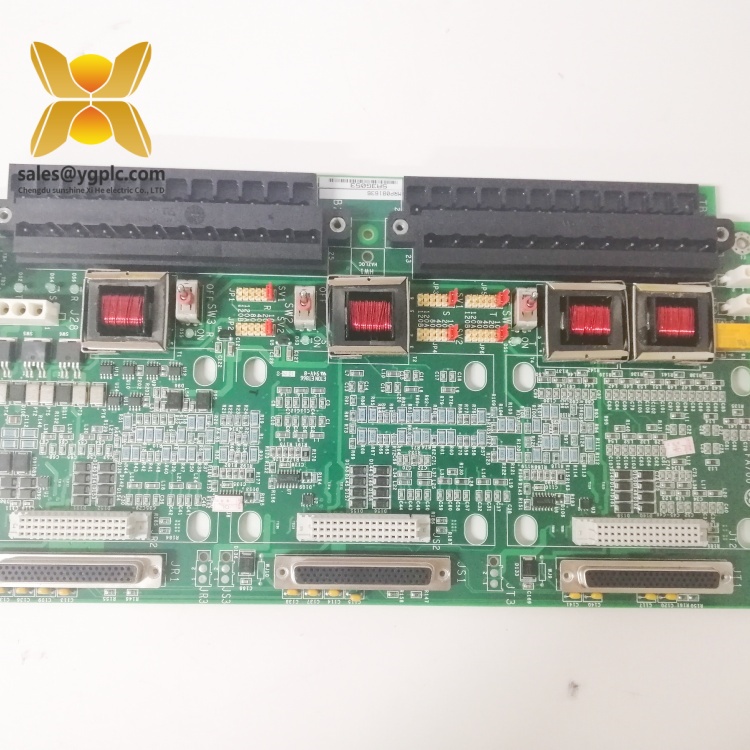

GE IS200TSVCH1A Turbine Speed Control Module

Product Overview: GE IS200TSVCH1A

The GE IS200TSVCH1A turbine speed control module is a high-precision industrial control component designed for GE’s Mark VIe Turbine Control System, a cornerstone of power generation and heavy machinery automation. As a critical part of this advanced platform, the IS200TSVCH1A regulates turbine rotational speed by processing feedback from speed sensors and adjusting control valves, ensuring stable operation in mission-critical applications. Engineered for reliability in harsh environments, this module combines robust hardware with advanced algorithms to maintain precise speed control for steam, gas, and hydro turbines.

Featuring dual-channel speed input processing and analog/digital output capabilities, the IS200TSVCH1A interfaces seamlessly with GE’s Mark VIe racks (e.g., IS200TBCBH1B) and communicates via Modbus RTU/TCP for real-time data exchange. Its -40°C to +70°C operating range and IP20 protection rating make it suitable for power plants, oil refineries, and manufacturing facilities. The module’s hot-swappable design allows maintenance without system shutdown, while built-in self-diagnostics enhance reliability by detecting faults early.

Within automation systems, the IS200TSVCH1A acts as a vital link between turbine mechanical systems and control networks, enabling precise speed regulation for optimal energy efficiency. Its compatibility with GE’s Proficy Machine Edition software and compliance with IEEE standards solidify its role in critical infrastructure, where uninterrupted operation is essential for grid stability and process continuity.

Technical Specifications: GE IS200TSVCH1A

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TSVCH1A |

| Manufacturer | GE |

| Product Type | Turbine Speed Control Module |

| Input Channels | 2 x speed sensor inputs (magnetic pickup) |

| Output Signals | 4–20 mA, 0–10 V DC, relay contacts |

| Communication Protocol | Modbus RTU/TCP |

| Physical Dimensions | 228.6 mm (H) × 127 mm (W) × 76.2 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | Rack-mounted (Mark VIe compatible) |

| Power Supply | 24V DC ±10% |

| Country of Origin | United States |

Main Features and Advantages: GE IS200TSVCH1A

Precision Speed Regulation: The IS200TSVCH1A maintains turbine speed within ±0.1% of setpoint, critical for power generation systems where frequency stability impacts grid performance. Its advanced PID control algorithms adapt to varying loads, ensuring smooth operation during start-up, load changes, and shutdown.

Redundant Design: Dual-speed input channels provide fault tolerance, with automatic switching to the secondary channel in case of failure. This redundancy minimizes downtime in critical applications like combined cycle power plants.

Real-Time Diagnostics: Built-in LED indicators and self-test routines monitor module health, while serial communication outputs enable remote fault detection. This proactive feature reduces troubleshooting time and maintenance costs.

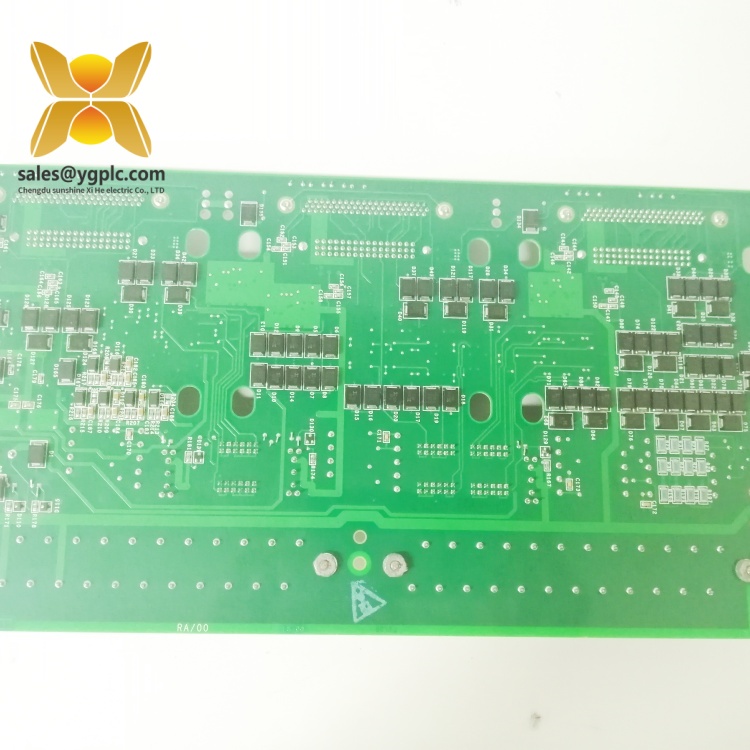

Industrial Durability: The module’s rugged metal enclosure and wide temperature range withstand high vibration and extreme conditions, making it suitable for turbine environments with constant mechanical stress.

Seamless System Integration: Compatible with GE’s Mark VIe ecosystem, the IS200TSVCH1A integrates effortlessly with HMI systems and supervisory controls, supporting centralized monitoring via SCADA platforms.

Application Areas: GE IS200TSVCH1A

The GE IS200TSVCH1A turbine speed control module is essential for industries requiring precise turbine management:

- Power Generation: Controls steam and gas turbines in thermal, combined cycle, and renewable energy plants, ensuring stable power output and grid synchronization.

- Oil and Gas: Manages compressor turbines in refineries and pipeline stations, optimizing flow rates and pressure while preventing over-speed conditions.

- Manufacturing: Regulates turbines in process industries like paper mills and chemical plants, where consistent speed is critical for product quality.

- Marine Engineering: Used in ship propulsion systems to maintain engine speed during course changes and load fluctuations, enhancing navigation safety.

- District Heating: Controls turbines in cogeneration plants, balancing power and heat output for efficient energy distribution.

Related Products: GE IS200TSVCH1A

- GE IS200TBCBH1B Rack Chassis: Houses the IS200TSVCH1A and other Mark VIe modules, providing mechanical support and power distribution.

- GE IS200TCCPH1A Control Processor Module: Coordinates system operations, working alongside the IS200TSVCH1A for comprehensive turbine control.

- GE IS200TCVOH1A Valve Control Module: Controls hydraulic valves based on speed data from the IS200TSVCH1A, adjusting turbine output.

- GE IS200TSSCH1A Speed Sensor Module: Provides speed feedback to the IS200TSVCH1A, ensuring accurate rotational data.

- GE IS200TPROS1A Proximity Switch Module: Monitors turbine shaft position, complementing the IS200TSVCH1A for comprehensive machinery protection.

- GE IS200TBAIH1A Bus Interface Module: Enables communication between the IS200TSVCH1A and other rack modules, enhancing system integration.

Installation and Maintenance: GE IS200TSVCH1A

Pre-installation Preparations:

Before installing the IS200TSVCH1A, verify the Mark VIe rack is properly grounded and powered (24V DC). Clean the rack slot and align the module with guides, securing it with retention brackets. Connect speed sensor cables to the designated terminals, ensuring shielded wiring to minimize EMI. Configure input parameters (e.g., speed range, output scaling) using GE’s Proficy software, and test signal integrity before commissioning.

Before installing the IS200TSVCH1A, verify the Mark VIe rack is properly grounded and powered (24V DC). Clean the rack slot and align the module with guides, securing it with retention brackets. Connect speed sensor cables to the designated terminals, ensuring shielded wiring to minimize EMI. Configure input parameters (e.g., speed range, output scaling) using GE’s Proficy software, and test signal integrity before commissioning.

Maintenance Recommendations:

- Routine Checks: Monthly visual inspections for loose connections, overheating, or damaged cables. Use the module’s LED indicators to verify operational status.

- Calibration: Annually calibrate speed inputs with a certified signal generator to maintain measurement accuracy. Reference GE’s procedures for step-by-step guidance.

- Firmware Updates: Periodically update firmware via the rack’s communication interface to access new features and safety patches.

- Spare Parts Management: Keep a spare IS200TSVCH1A on hand, leveraging our global supply chain for quick replacement of discontinued components.

Product Guarantee: GE IS200TSVCH1A

Our company provides a 12-month quality warranty for the GE IS200TSVCH1A turbine speed control module, covering non-human-induced hardware defects. During the warranty period, we will replace any module with output inconsistencies, communication failures, or physical damage at no cost. For urgent needs or discontinued models, our extensive inventory and global logistics network ensure prompt fulfillment, minimizing downtime and supporting continuous operation.

GE IS200PMCIH1ABA | Communication and Interface Module | IS200TDBSH2ACC

GE IS200SAMBH1ABA | Sensor Interface Module for Mark VIe Turbine Control System | IS200STCIH2A

GE IS200STAOH2AAA | Synchronizer Module (Gas Turbine Control) | IS200SPIDG1ABA

GE IS200STCIH2A | Turbine Control Interface Module | IS200PMCIH1ABA

GE IS200TBAIH1CCC | Mark VIe Terminal Block Interface Module | IS200SRTDH2ACB

GE IS200TBCIS2CCD | Mark VIe Terminal Block Interface Module | IS200TDBTH6ACD

GE IS200TDBSH2ACC | Mark VIe Terminal Base Module |

GE IS200TDBTH6ABC | Terminal Board Module | IS200TPROH1BCB

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: