Description

GE IS200TREAH2AED Turbine Control Module

Product Overview

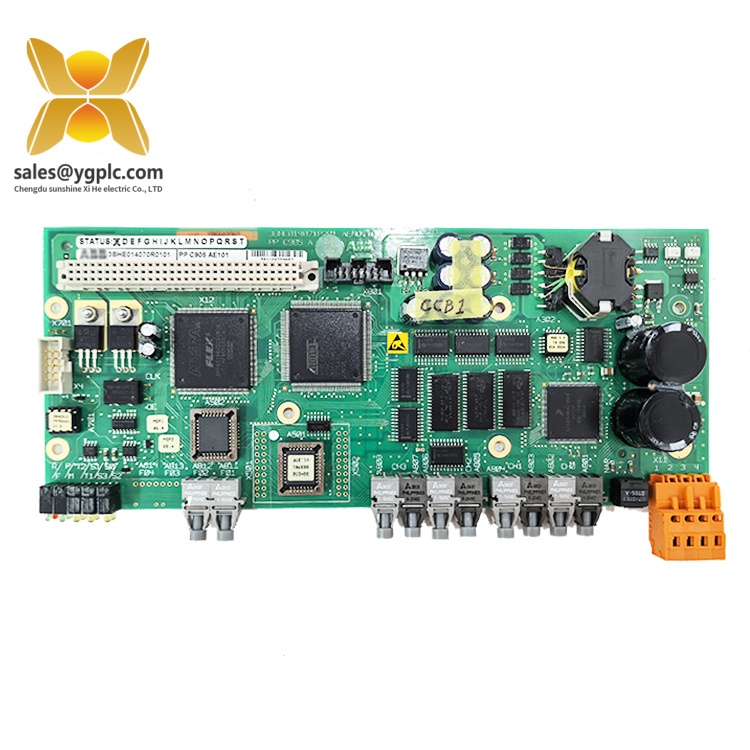

The GE IS200TREAH2AED is a high-performance turbine control module designed as a critical component of GE’s Mark VIe Distributed Control System (DCS), specializing in steam and gas turbine management for industrial automation. Engineered to deliver precise control and monitoring of turbine operations, this module forms the core of power generation and process control systems in sectors such as energy, oil & gas, and manufacturing. As part of the IS200 Series, the IS200TREAH2AED integrates seamlessly with other Mark VIe components (e.g., input/output modules, communication gateways), enabling real-time adjustment of turbine speed, load, and safety interlocks.

Featuring a rugged industrial design, the GE IS200TREAH2AED supports advanced control algorithms for turbine start-up, shutdown, and load sharing, ensuring stable operation under varying conditions. Its dual-core processor architecture enables high-speed data processing (up to 200 MIPS) and redundant communication paths, minimizing latency in critical control loops. The module’s non-volatile memory preserves configurations during power outages, while built-in diagnostic tools monitor component health and signal integrity. With a wide operating temperature range (-40°C to +70°C) and compliance with industry standards (e.g., IEC 61131-2), the IS200TREAH2AED ensures reliable performance in harsh industrial environments.

In automation ecosystems, the IS200TREAH2AED serves as the brain of turbine control systems, converting field signals from sensors (e.g., temperature, pressure, speed) into precise control commands for actuators and valves. Its compatibility with GE’s Proficy software suite allows intuitive programming and remote monitoring, while support for protocols like Modbus and Ethernet/IP enables integration with enterprise-level SCADA systems. By balancing precision control with robust fault tolerance, this module optimizes energy efficiency, reduces maintenance costs, and prevents unplanned downtime in mission-critical applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TREAH2AED |

| Manufacturer | GE |

| Product Type | Turbine Control Module |

| Platform | Mark VIe DCS |

| Processor | Dual-core, 200 MIPS |

| Memory | 512 MB flash, 256 MB RAM |

| Communication Interfaces | Ethernet (10/100 Mbps), RS-485, Profibus DP |

| Input Voltage | 24 V DC ±10% |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.9 kg |

| Operating Temperature | -40°C to +70°C |

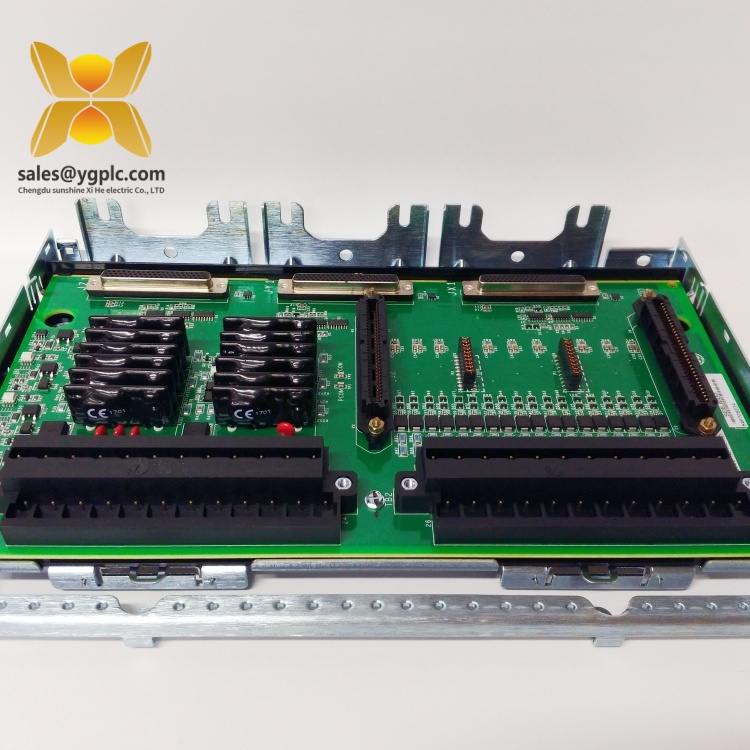

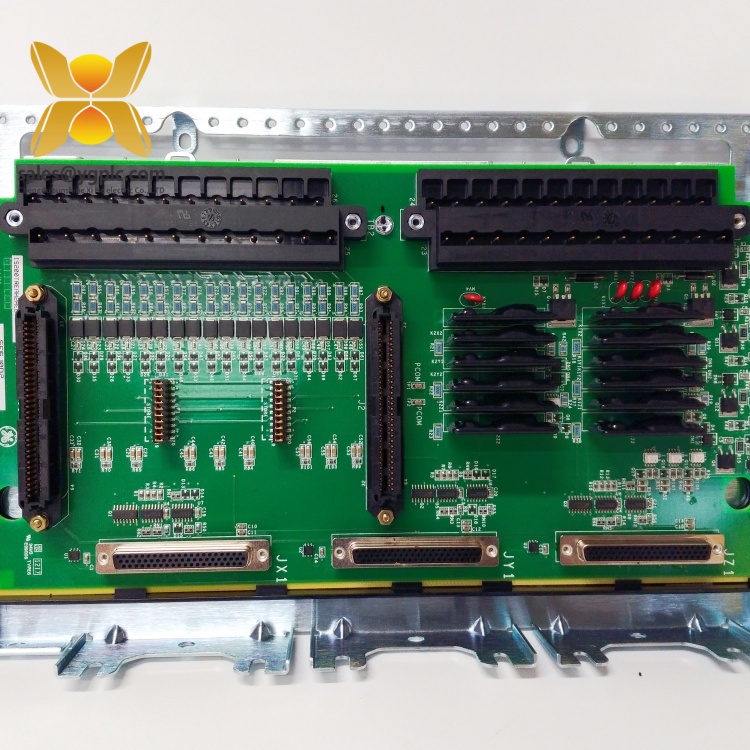

| Mounting | Rack-mounted in Mark VIe enclosure |

| Certifications | CE, UL, cUL, IEC 61131-2 |

Key Features and Advantages

Advanced Turbine Control Algorithms: The IS200TREAH2AED incorporates specialized firmware for turbine speed governing, load sharing, and emergency shutdown, ensuring stable operation across varying loads. Its adaptive control logic adjusts to changing process conditions, optimizing fuel efficiency and reducing mechanical stress.

Redundant Architecture: Dual-core processing and redundant power/communication paths eliminate single points of failure, maintaining control during component malfunctions. This redundancy is critical for 24/7 operations in power plants and refineries.

High-Speed Data Processing: With 200 MIPS performance, the module executes complex control loops in microseconds, enabling real-time response to turbine speed fluctuations and transient loads. This speed is essential for maintaining grid stability in power generation.

Comprehensive Diagnostics: Built-in self-test functions monitor processor health, memory usage, and communication integrity, providing real-time alerts via LED indicators and diagnostic software. This proactive approach reduces troubleshooting time and enhances system availability.

Rugged Industrial Design: The module’s metal enclosure and conformal-coated circuitry withstand extreme temperatures, vibration, and electromagnetic interference, making it suitable for harsh environments like offshore platforms and industrial boiler rooms.

Seamless System Integration: Compatible with GE’s Mark VIe I/O modules (e.g., IS200AAHAH2ADC analog inputs) and communication gateways, the IS200TREAH2AED supports scalable control systems, from small turbines to large power plant clusters.

Application Areas

The GE IS200TREAH2AED is essential for turbine control in industries requiring precise power generation and process optimization:

- Power Generation: Manages steam and gas turbines in thermal, combined-cycle, and renewable energy plants, ensuring stable power output and grid synchronization. It regulates speed during load changes and coordinates with other generators in parallel operations.

- Oil & Gas: Controls gas turbines in pipeline compression stations and refineries, adjusting speed to match flow demands while maintaining safety interlocks. It also manages steam turbines for process heating in petrochemical plants.

- Manufacturing: Operates steam turbines for power generation and mechanical drive applications in paper mills, chemical plants, and food processing facilities, optimizing energy use and production efficiency.

- Marine and Aerospace: Used in shipboard turbine systems and test stands for aircraft engine validation, meeting rigorous performance and safety standards.

Specific applications include:

- Turbine Speed Governing: Maintains precise rotational speed during start-up, normal operation, and shutdown, preventing overspeeding and ensuring compliance with grid regulations.

- Load Sharing in Power Plants: Coordinates multiple turbines to distribute electrical load efficiently, adapting to fluctuating demand while minimizing fuel consumption.

- Emergency Shutdown Systems: Triggers rapid shutdowns in case of abnormal conditions (e.g., overpressure, overspeed), protecting equipment from catastrophic failure.

Related Products

- IS200AAHAH2ADC Analog Input Module: Works with the IS200TREAH2AED to acquire temperature, pressure, and flow data for turbine control.

- IS200TCTGG1A Turbine Control Module: A complementary module for advanced turbine protection, integrating with the IS200TREAH2AED for comprehensive health monitoring.

- IS200DSVIH1BAA Digital Output Module: Sends control signals from the IS200TREAH2AED to actuators and valves, enabling precise mechanical control.

- IS200COMM Communication Module: Enables Ethernet connectivity for the IS200TREAH2AED, supporting remote monitoring via SCADA systems.

- IS200PWR Power Supply Module: Provides redundant power to the IS200TREAH2AED and other Mark VIe modules, ensuring uninterrupted operation.

- IS200TBCH Terminal Block Module: Simplifies field wiring for the IS200TREAH2AED, reducing installation time and errors.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE IS200TREAH2AED, ensure the Mark VIe rack is properly grounded and ventilated. Verify power supply compatibility (24 V DC) and install redundant power modules for reliability. Mount the module in the rack using anti-vibration brackets, ensuring adequate spacing for heat dissipation. Connect communication cables (Ethernet, Profibus) and field wiring to compatible I/O modules, using shielded cables to minimize electromagnetic interference. Use GE’s Proficy software to configure control parameters, such as speed setpoints and alarm thresholds, before commissioning.

Before installing the GE IS200TREAH2AED, ensure the Mark VIe rack is properly grounded and ventilated. Verify power supply compatibility (24 V DC) and install redundant power modules for reliability. Mount the module in the rack using anti-vibration brackets, ensuring adequate spacing for heat dissipation. Connect communication cables (Ethernet, Profibus) and field wiring to compatible I/O modules, using shielded cables to minimize electromagnetic interference. Use GE’s Proficy software to configure control parameters, such as speed setpoints and alarm thresholds, before commissioning.

Maintenance Suggestions:

- Routine Inspections: Quarterly checks of LED indicators to verify module health and secure connections. Use Proficy software to review diagnostic logs for error codes or performance anomalies.

- Firmware Updates: Periodically update the module’s firmware to incorporate bug fixes and new features, following GE’s validated procedures to avoid configuration loss.

- Environmental Management: Monthly cleaning of air vents to prevent dust accumulation, especially in dusty environments. Maintain control room temperature (20–25°C) and humidity (40–60%) to optimize component lifespan.

- Spare Parts Management: Store spare IS200TREAH2AED modules in static-free packaging at room temperature, testing annually to ensure functionality for urgent replacements.

Product Guarantee

Our company provides a 12-month quality warranty for the GE IS200TREAH2AED, covering hardware defects under normal use. In the event of operational issues—such as processing delays or communication failures—we offer prompt replacement services to minimize downtime. For legacy or discontinued models like the IS200TREAH2AED, our global supply chain specializes in sourcing rare components, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation, programming, and troubleshooting, delivering reliable solutions to maintain your turbine control systems.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IS200SPROH1AAB MRP663860 | Turbine Protection Relay Module | IS200SRTDH2ACB

GE IS200SRTDH2ACB | Mark VIe RTD Input Module | IS200STCIH2A

GE IS200TBAIH1CCC | Mark VIe Terminal Block Interface Module | IS200SRTDH2ACB

GE IS200TBCIH1BBC | Contact Terminal Board, Mark VIe Series | IS200TDBSH2ACC

GE IS200TDBSH2ACC | Mark VIe Terminal Base Module |

GE IS200TDBTH6ABC | Terminal Board Module | IS200TPROH1BCB

GE IS200TDBTH6ACD | Terminal Board Module | IS200TVIBH2BBB

GE IS200TPROH1BBB | Mark VIe Turbine Protection Module | IS200TBCIH2CAA

GE IS200TDBTH6ABC | Terminal Board Module | IS200TPROH1BCB

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: