Description

GE IS200TPROS1CBB Product Specification

Product Overview

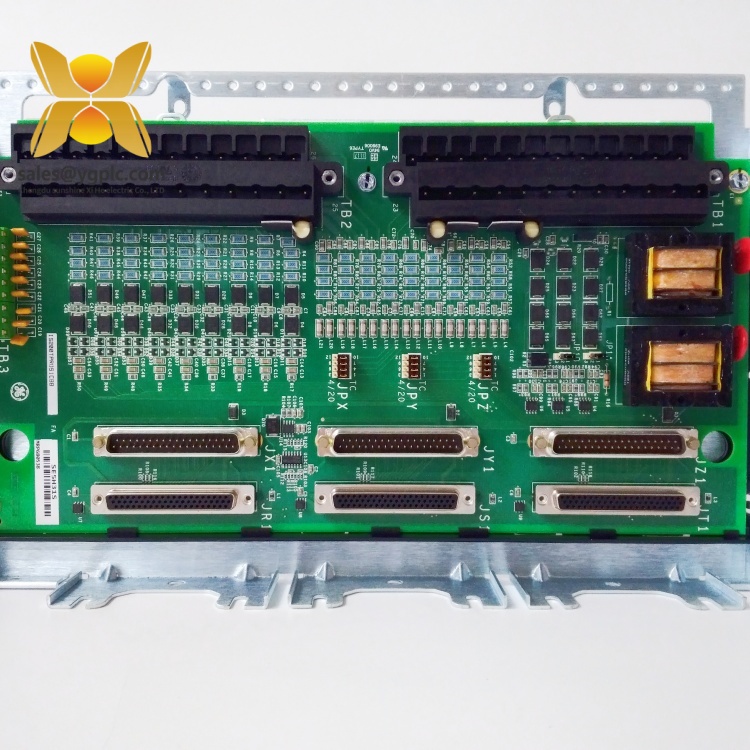

The GE IS200TPROS1CBB is a high-performance digital input/output (DIO) module designed for GE’s Mark VIe Turbine Control System, a cornerstone of industrial automation in power generation, oil and gas, and heavy machinery industries. Engineered to provide precise, real-time monitoring and control of critical operations, the GE IS200TPROS1CBB integrates seamlessly with PLCs, HMIs, and supervisory control systems, enabling reliable automation of steam and gas turbine processes. As part of the Mark VIe series, this module supports up to 16 channels of digital signals, making it ideal for applications requiring high-density I/O functionality in harsh industrial environments.

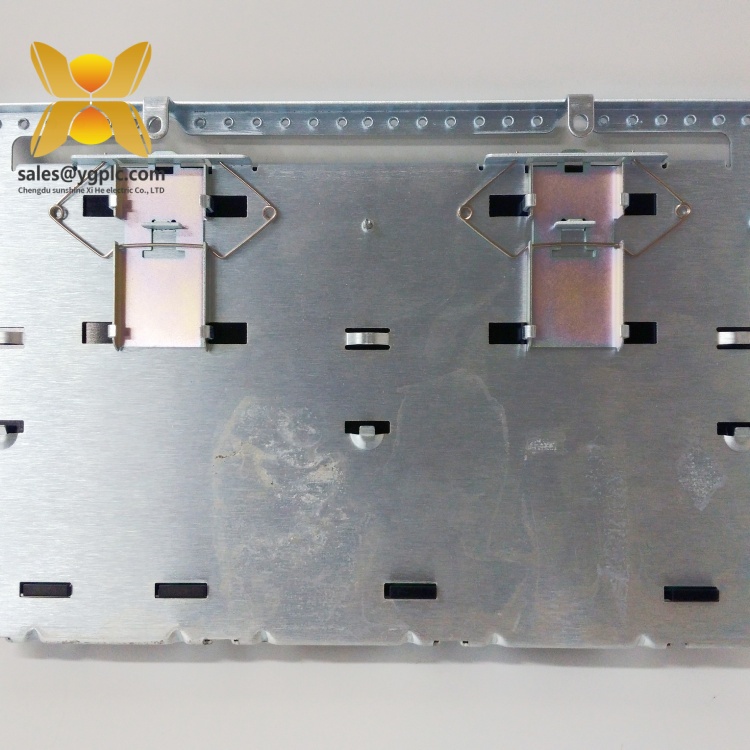

The GE IS200TPROS1CBB processes signals from proximity switches, pressure sensors, and other field devices, converting them into standardized digital outputs for centralized control. Its software-configurable design allows users to customize signal thresholds, debounce times, and diagnostic parameters, ensuring optimal performance across diverse operational scenarios. The module’s rugged construction features an IP20-rated enclosure and conformal-coated PCBs, safeguarding against dust, moisture, and electromagnetic interference (EMI), while its compact form factor (100 mm × 160 mm × 30 mm) and lightweight design (0.8 kg) facilitate easy installation in 19” control racks.

In automation architectures, the GE IS200TPROS1CBB acts as a critical interface between field sensors and higher-level control systems, ensuring accurate and timely data transmission. Its high-speed processing capabilities (up to 10 kHz signal response) enable real-time monitoring of rotational speed, valve positions, and safety interlocks in turbines and compressors. By delivering reliable DIO functionality, the module enhances operational efficiency, minimizes downtime, and supports predictive maintenance strategies in mission-critical industrial settings.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200TPROS1CBB |

| Manufacturer | General Electric (GE) |

| Product Type | Digital Input/Output (DIO) Module |

| Input Channels | 16 channels (digital inputs) |

| Output Channels | 16 channels (digital outputs) |

| Signal Types | TTL/CMOS (0–5 VDC), dry contacts |

| Communication Protocol | Ethernet/IP, Profibus DP |

| Power Supply | 24 VDC ±10% |

| Physical Dimensions | 100 mm (W) × 160 mm (H) × 30 mm (D) |

| Weight | 0.8 kg |

| Operating Temperature | -20°C to +60°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, ISO 16132 |

Main Features and Advantages

High-Density I/O Capability: The GE IS200TPROS1CBB supports 16 digital input and output channels, allowing simultaneous monitoring and control of multiple field devices. This feature is ideal for large-scale turbine control systems requiring extensive signal integration.

Configurable Signal Processing: Users can adjust signal filtering, hysteresis, and diagnostic parameters via GE’s Proficy software, ensuring compatibility with a wide range of sensors and actuators. The module’s self-diagnostics include channel health monitoring and fault reporting, reducing troubleshooting time.

Rugged Industrial Design: Built to withstand harsh environments, the module’s IP20 enclosure and conformal coatings protect against dust, oil mist, and voltage surges. Its shock- and vibration-resistant construction meets ISO 10816 standards, making it suitable for heavy machinery applications.

Hot-Swap Functionality: The GE IS200TPROS1CBB supports hot-swappable installation, enabling maintenance or replacement without powering down the system. This minimizes downtime in critical operations, such as power plant turbine control.

Scalable System Integration: As part of the Mark VIe series, the module integrates seamlessly with other GE components (e.g., IS220PAOCH1A power supply, IS200TPCAG1B processor) to form a cohesive automation platform. Its Ethernet/IP and Profibus interfaces ensure compatibility with third-party PLCs and SCADA systems.

Application Areas

The GE IS200TPROS1CBB is widely deployed in industries requiring precise digital control and monitoring of rotating equipment:

-

Power Generation:

- Monitors steam turbine speed, valve positions, and safety interlocks in thermal and combined-cycle power plants, ensuring stable energy production and grid synchronization.

- Integrates with generator control systems to manage start/stop sequences, load sharing, and protective relaying.

-

Oil and Gas:

- Controls compressor anti-surge valves and monitors pipeline pressure switches in refineries and offshore platforms, enhancing process safety and efficiency.

- Supports emergency shutdown (ESD) systems by interfacing with flame detectors and pressure sensors in chemical processing facilities.

-

Heavy Machinery Manufacturing:

- Manages robotic arm movements and conveyor belt operations in automotive and steel production plants, improving cycle times and reducing material waste.

- Monitors hydraulic system pressures and position feedback in forging presses and CNC machines.

-

Water/Wastewater Treatment:

- Automates pump stations and valve actuators in water distribution networks, optimizing flow rates and reducing energy consumption.

- Integrates with level sensors and chemical dosing systems in wastewater treatment plants for real-time process control.

Related Products

- GE IS220PAOCH1A: A redundant power supply module that provides stable 24 VDC to the GE IS200TPROS1CBB and other Mark VIe components, ensuring uninterrupted operation.

- GE IS200TPCAG1B: A processor module that coordinates data exchange between the GE IS200TPROS1CBB and higher-level control systems, enabling advanced logic and sequencing.

- GE IS200TCTBH1A: A thermocouple input module that complements the GE IS200TPROS1CBB by providing temperature monitoring capabilities in turbine systems.

- GE IS200TSVCH1A: A voltage/current input module for analog signals, often used alongside the GE IS200TPROS1CBB for hybrid I/O applications.

- GE IS200TURTH1B: A turbine monitoring module that integrates vibration and axial position data, working in tandem with the GE IS200TPROS1CBB for comprehensive machinery health analysis.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IS200TPROS1CBB, ensure the following:

Before installing the GE IS200TPROS1CBB, ensure the following:

- Verify the control rack is properly grounded to prevent electrostatic discharge (ESD). Use a multimeter to confirm the power supply voltage (24 VDC ±10%) and inspect wiring for damage.

- Clean the installation area to remove dust and debris, and ensure adequate airflow around the module (minimum 50 mm clearance).

- Use GE’s Proficy software to configure channel settings (e.g., input types, alarm thresholds) based on the specific application requirements. Mount the module in the rack using the provided DIN rail brackets, ensuring secure mechanical and electrical connections.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks of front-panel LEDs (green for normal operation, amber for faults) and cleaning of ventilation slots to prevent dust accumulation.

- Functional Testing: Quarterly verification of signal integrity using a calibration tool to simulate input signals and confirm output responses.

- Firmware Updates: Periodically update the module’s firmware via GE’s software to access new features and security patches, particularly when integrating with updated control systems.

- Spare Parts Management: Maintain a stock of GE IS200TPROS1CBB modules and replacement components (e.g., terminal blocks) to address unexpected failures promptly.

Product Guarantee

Our company provides a one-year quality warranty for the GE IS200TPROS1CBB, covering hardware malfunctions due to defects in materials or workmanship. During the warranty period, we will replace any module that exhibits abnormal signal behavior or functional failures. For discontinued models like the GE IS200TPROS1CBB, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support, including calibration services and repair solutions, to help maintain your equipment’s reliability throughout its lifecycle.

Leveraging our 17 years of expertise in industrial control distribution, we guarantee prompt delivery and comprehensive technical assistance. Our supply chain network enables quick responses to customer demands, even for hard-to-find or obsolete components, ensuring minimal downtime for critical systems.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data derived from GE’s official specifications and industry applications. For detailed installation guidelines, refer to the GE IS200TPROS1CBB user manual or contact our technical support team for personalized assistance.

GE IS200ERIOH1AAA | I/O Module for Mark VIe System | IS200PMCIH1AAA6BA00

GE IS200STCIH2A | Turbine Control Interface Module | IS200PMCIH1ABA

GE IS200TDBTH6ABC | Terminal Board Module | IS200TPROH1BCB

GE IS200SAMBH1ABA | Sensor Interface Module for Mark VIe Turbine Control System | IS200STCIH2A

GE IS200TBAIH1CCC | Mark VIe Terminal Block Interface Module | IS200SRTDH2ACB

GE IS200SDIIH1ADB MRP683026 | Mark VIe Digital Input Module | IS200TBCIH1BBC

GE IS200TBCIH2CAA | Terminal Block Interface Module | IS200TBCIS2CCD

GE IS200TBCIH2CAA | Terminal Block Interface Module | IS200TBCIS2CCD

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: