Description

GE IS200TDBTH6ACD Product Specification

Product Overview

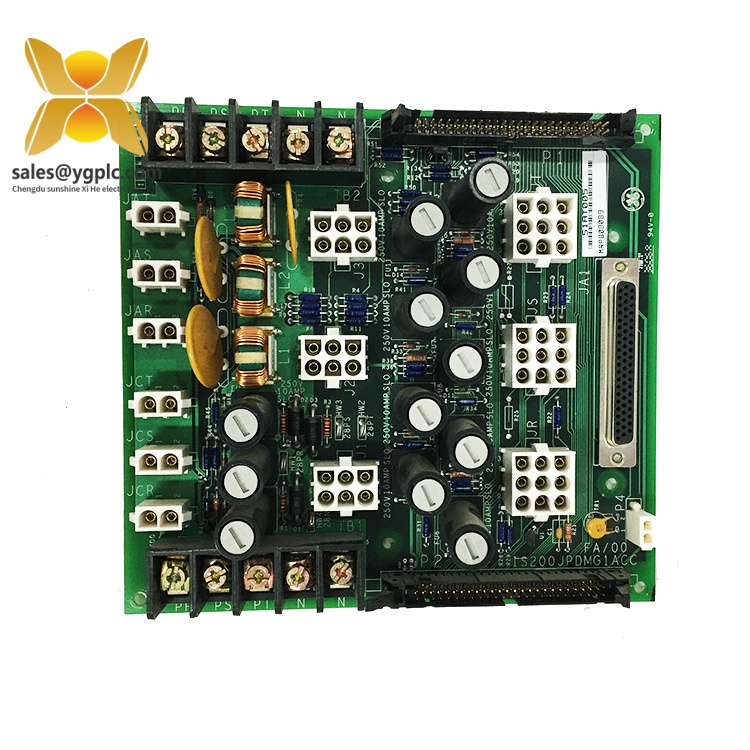

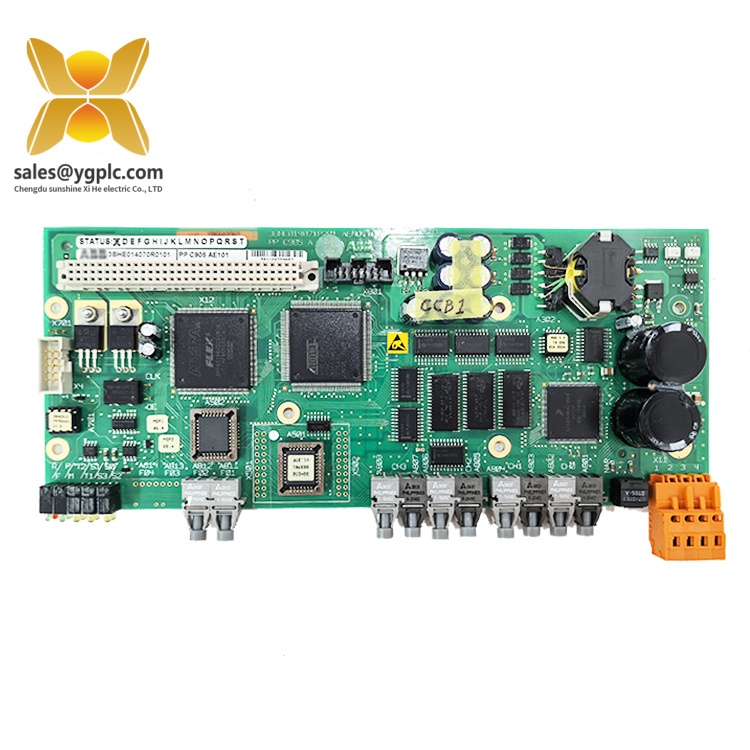

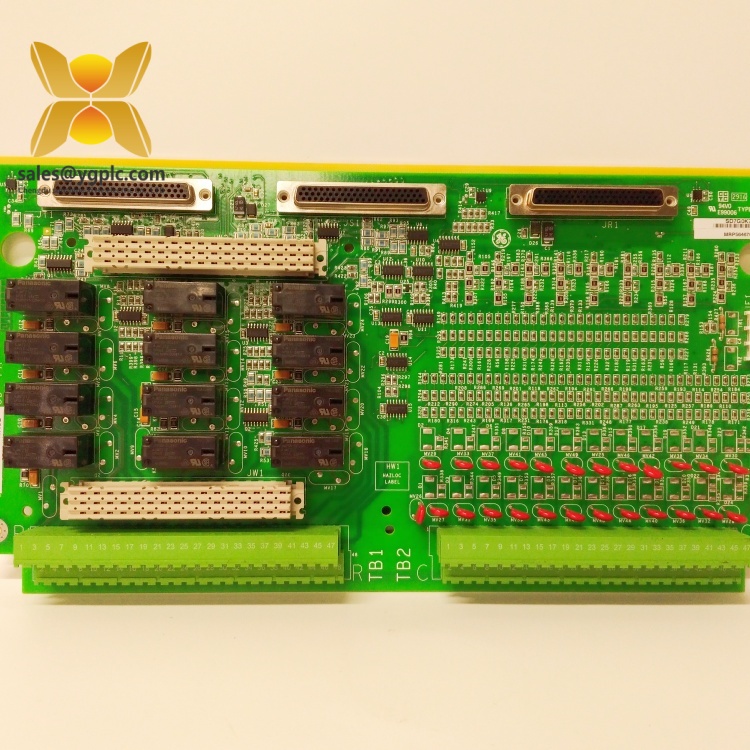

The GE IS200TDBTH6ACD is a high-reliability terminal board module engineered for GE’s Mark VIe Turbine Control System, a cornerstone of industrial automation in power generation and heavy machinery control. As a critical interface component, this module serves as a connection hub between field devices and the control system, enabling seamless signal transmission for turbine monitoring and control. The GE IS200TDBTH6ACD is designed to withstand harsh industrial environments, making it ideal for applications in power plants, oil and gas facilities, and manufacturing plants where reliable connectivity is non-negotiable.

Part of GE’s IS200 series, the GE IS200TDBTH6ACD features a rugged design with 32 isolated terminal connections, supporting both analog and digital signals. It integrates the Mark VIe system’s high-speed data bus, ensuring real-time communication between sensors, actuators, and the central control unit. The module’s compact form factor (240 mm × 170 mm × 80 mm) and lightweight construction (1.5 kg) facilitate easy installation in control cabinets, while its 24 VDC power supply and wide operating temperature range (-40°C to +70°C) ensure stability in demanding conditions.

In automation systems, the GE IS200TDBTH6ACD acts as a physical interface bridge, translating field signals into protocols compatible with the Mark VIe system. Its isolated terminals prevent cross-talk and electrical interference, enhancing the reliability of turbine control loops. By combining robust hardware with industry-standard connectivity, the module supports critical operations such as steam turbine speed regulation, generator excitation control, and emergency shutdown systems, minimizing downtime and optimizing operational efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200TDBTH6ACD |

| Manufacturer | General Electric (GE) |

| Product Type | Terminal Board Module |

| Terminal Connections | 32 isolated terminals (16 input, 16 output) |

| Signal Types | Analog (4–20 mA, 0–10 VDC), digital (TTL/CMOS) |

| Power Supply | 24 VDC ±10% |

| Communication Protocol | Proprietary to GE Mark VIe system |

| Physical Dimensions | 240 mm (W) × 170 mm (H) × 80 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Shock Resistance | 50 G (11 ms, half-sine) |

| Vibration Resistance | 2 G (5–200 Hz, continuous) |

| Certifications | CE, UL |

Main Features and Advantages

High-Density Terminal Configuration: The GE IS200TDBTH6ACD offers 32 isolated terminals, supporting a mix of analog and digital signals for versatile connectivity. This high density reduces the need for additional interface modules, optimizing space in control cabinets.

Electrical Isolation: Each terminal is electrically isolated to prevent ground loops and electromagnetic interference (EMI), ensuring signal integrity in noisy industrial environments. This feature is critical for maintaining accurate measurements in turbine control applications.

Rugged Industrial Design: Constructed with a metal enclosure and conformal-coated PCBs, the module withstands extreme temperatures, humidity, and vibration. Its rugged design makes it suitable for harsh environments, including power plant turbine halls and offshore platforms.

Seamless System Integration: Designed specifically for GE’s Mark VIe system, the GE IS200TDBTH6ACD integrates seamlessly with other IS200 series modules (e.g., CPU, communication cards), eliminating compatibility issues and simplifying system setup.

Hot-Swappable Design: The module supports hot swapping, allowing replacement without powering down the control system. This feature minimizes downtime during maintenance, the essential for 24/7 operational settings.

Application Areas

The GE IS200TDBTH6ACD is widely applied in industries requiring reliable signal conditioning for critical machinery:

-

Power Generation:

- Connects steam turbine sensors (temperature, pressure, vibration) to the Mark VIe control system, enabling precise speed regulation and load sharing in power plants.

- Facilitates generator excitation control by transmitting analog signals from voltage regulators to the central control unit.

-

Oil and Gas:

- Integrates with gas turbine control systems in refineries and pipeline compressor stations, ensuring safe and efficient operation.

- Supports emergency shutdown (ESD) systems by providing reliable signal paths for shutdown valves and alarms.

-

Manufacturing:

- Connects robotic arm sensors and actuators in automotive plants to the control system, enabling high-precision motion control.

- Transmits process data from chemical reactors to PLCs in pharmaceutical manufacturing, ensuring batch consistency.

-

Water/Wastewater Treatment:

- Links pump control signals to SCADA systems in water treatment plants, maintaining consistent flow rates and pressure.

- Transmits level sensor data from wastewater treatment tanks to control valves, optimizing treatment processes.

Related Products

- GE IS200TCCPH1AAA: A control processor module for the Mark VIe system, working in tandem with the GE IS200TDBTH6ACD to process terminal signals.

- GE IS200TBNCH1AA: A power supply module that provides stable 24 VDC to the GE IS200TDBTH6ACD and other Mark VIe components.

- GE IS200TBQBH2AA: A communication interface module that enables the GE IS200TDBTH6ACD to connect with Ethernet/IP networks for remote monitoring.

- GE IS200TBSCH1AA: A sensor interface module that expands the GE IS200TDBTH6ACD with additional analog input channels for vibration sensors.

- GE IS200TBCCH1AA: A bus communication module that enhances data transfer between the GE IS200TDBTH6ACD and other Mark VIe modules.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IS200TDBTH6ACD, ensure the following:

Before installing the GE IS200TDBTH6ACD, ensure the following:

- Verify the power supply meets 24 VDC ±10% and that the control cabinet is properly grounded to prevent electrostatic discharge (ESD). Use a multimeter to confirm voltage stability.

- Use GE’s Proficy Machine Edition software to configure terminal assignments (analog/digital) and signal ranges based on field device specifications.

- Mount the module in a 19″ rack with at least 30 mm of clearance for airflow, securing it with the provided brackets to minimize vibration.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks for loose connections, damaged terminals, or signs of overheating. Clean dust from the enclosure using a static-free brush.

- Signal Testing: Quarterly verification of signal integrity using a multimeter to ensure accurate voltage/current transmission through each terminal.

- Environmental Monitoring: Regularly assess ambient temperature and humidity levels to ensure they remain within the module’s operational range.

- Firmware Updates: Periodically update the module’s firmware via GE’s software to ensure compatibility with the latest Mark VIe system releases.

Product Warranty

Our company provides a one-year quality warranty for the GE IS200TDBTH6ACD, covering hardware failures due to non-human factors. During the warranty period, we will replace any module that exhibits signal transmission issues or functional defects. For discontinued models like the GE IS200TDBTH6ACD, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support and repair services to maintain your system’s reliability over its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data from GE’s official specifications and industry applications. For detailed installation guidelines, refer to the GE IS200TDBTH6ACD user manual or contact our technical support team.

GE IS200DTAIH1ACC | Digital Input Module | IS200DTAOH1ABA

GE IS200DTAOH1ABA | Mark VIe Digital Input Module | IS200EGDMH1AFF

GE IS200ECTBG1ADE | Exciter Contact Terminal Board | IS200EPSMG1AED

GE IS200EGDMH1ADF | Ethernet Communication Module | IS200ERIOH1AAA

GE IS200EPSMG1AED | Mark VIe Power Supply Module | IS200EROCH1ABB

GE IS200EPSMG1AEC | Power Supply Module for Mark VIe System | IS200ERDDH1ABA

GE IS200EGDMH1ADF | Ethernet Communication Module | IS200ERIOH1AAA

GE IS200ERIOH1ABB | Mark VIe Remote I/O Module | IS200ISBBG2AAB

GE IS200JPDDG1AAA | Digital Input Module | IS200SPIDG1ABA

GE IS200EXHSG3REC | Excitation Control Module | IS200EROCH1ABB

GE IS200DTAOH1ABA | Mark VIe Digital Input Module | IS200EGDMH1AFF

GE IS200ECTBG1ADE | Exciter Contact Terminal Board | IS200EPSMG1AED

GE IS200EGDMH1ADF | Ethernet Communication Module | IS200ERIOH1AAA

GE IS200EPSMG1AED | Mark VIe Power Supply Module | IS200EROCH1ABB

GE IS200EPSMG1AEC | Power Supply Module for Mark VIe System | IS200ERDDH1ABA

GE IS200EGDMH1ADF | Ethernet Communication Module | IS200ERIOH1AAA

GE IS200ERIOH1ABB | Mark VIe Remote I/O Module | IS200ISBBG2AAB

GE IS200JPDDG1AAA | Digital Input Module | IS200SPIDG1ABA

GE IS200EXHSG3REC | Excitation Control Module | IS200EROCH1ABB

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: