Description

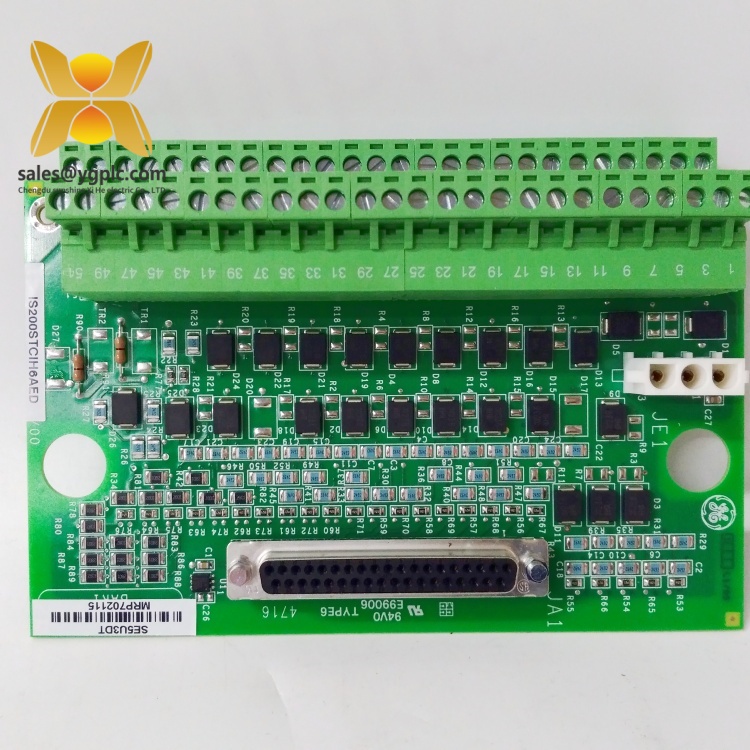

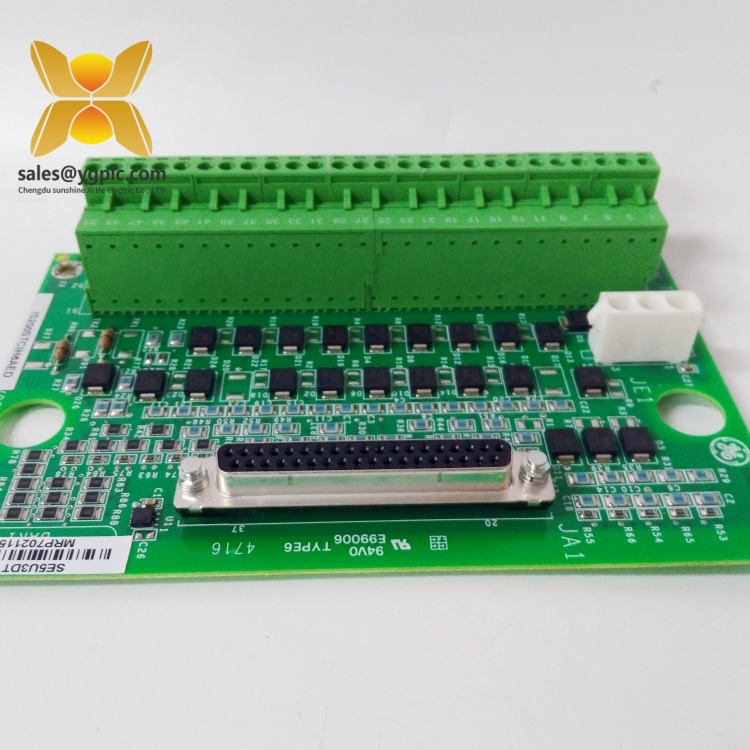

GE IS200STCIH2A Turbine Control Interface Module

Product Overview: GE IS200STCIH2A

The GE IS200STCIH2A turbine control interface module is a high-reliability industrial component designed for GE’s Mark VIe Turbine Control System, a flagship platform for steam and gas turbine automation. Engineered to serve as a critical interface between turbine sensors and the control system, this module processes analog and digital signals from field devices, enabling precise control and monitoring of turbine operations in power generation and industrial processes. The IS200STCIH2A integrates seamlessly with GE’s Mark VIe architecture, ensuring real-time data exchange and dynamic response to maintain optimal turbine performance.

Featuring a 32-bit microprocessor and advanced signal conditioning circuitry, the IS200STCIH2A supports multiple input/output configurations, including 4–20 mA analog signals and discrete inputs/outputs. Its dual-channel communication interface (Ethernet and serial) facilitates high-speed data transfer to supervisory control systems, while built-in diagnostic tools provide real-time health monitoring. The module’s -40°C to +70°C operating range and IP20 protection rating make it suitable for harsh industrial environments, including power plants, refineries, and manufacturing facilities.

As a key component of the Mark VIe system, the IS200STCIH2A plays a pivotal role in turbine speed control, load sharing, and safety interlock systems. Its compatibility with GE’s Proficy™ software suite and compliance with IEEE and NEMA standards ensure seamless integration into complex automation ecosystems, enhancing system reliability and reducing downtime. By enabling precise control and predictive maintenance, this module optimizes turbine efficiency and extends equipment lifespan, making it an indispensable asset for industries reliant on continuous power generation.

Technical Specifications: GE IS200STCIH2A

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200STCIH2A |

| Manufacturer | GE |

| Product Type | Turbine Control Interface Module |

| Input Voltage | 24V DC ±10% |

| I/O Channels | 8 analog inputs, 4 analog outputs, 16 discrete I/O |

| Communication Protocols | Modbus TCP/IP, RS485 |

| Physical Dimensions | 228.6 mm (H) × 127 mm (W) × 76.2 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | Rack-mounted (GE Mark VIe compatible) |

| Compliance | IEEE 1511, NEMA ICS 6 |

| Country of Origin | United States |

Main Features and Advantages: GE IS200STCIH2A

Precision Signal Processing: The IS200STCIH2A employs advanced analog-to-digital conversion (16-bit ADC) to ensure accurate representation of turbine sensor data, enabling precise control of speed, pressure, and temperature parameters. This precision is critical for maintaining turbine efficiency and preventing operational anomalies.

Robust Communication Capability: With dual communication channels, the module supports real-time data transmission to SCADA systems and human-machine interfaces (HMIs), facilitating remote monitoring and proactive maintenance. Its Modbus compatibility ensures seamless integration with third-party control systems.

Industrial-Grade Durability: Built with a rugged metal enclosure and wide temperature tolerance, the IS200STCIH2A withstands high vibration, dust, and electromagnetic interference common in power plant environments. This durability reduces maintenance needs and extends service life.

Hot-Swappable Design: The module allows replacement without system shutdown, minimizing downtime during maintenance or component failure. This feature is vital for industries where turbine downtime translates to significant financial loss.

Comprehensive Diagnostics: Integrated self-test routines and LED status indicators enable quick fault identification, reducing troubleshooting time. The module’s diagnostic capabilities support predictive maintenance strategies by alerting operators to potential issues before they escalate.

Application Areas: GE IS200STCIH2A

The GE IS200STCIH2A turbine control interface module is essential for industries relying on turbine-driven power generation and mechanical systems:

- Power Generation: Deployed in thermal, combined-cycle, and renewable energy plants to control steam and gas turbines, ensuring stable power output and grid synchronization. The module manages critical parameters like speed, load, and exhaust temperature.

- Oil and Gas: Used in refineries and pipeline compressor stations to regulate turbine-driven pumps and compressors, optimizing fluid flow and pressure while maintaining safety standards.

- Manufacturing: Integrates with steam turbines in paper mills, chemical plants, and pharmaceutical facilities to control process heating and power generation, supporting continuous production cycles.

- Marine and Aerospace: Installed in shipboard power plants and aircraft ground support equipment, where reliable turbine control is critical for mission-critical operations.

- District Heating: Manages turbines in district heating systems, adjusting power output to meet fluctuating thermal demand while maximizing energy efficiency.

Related Products: GE IS200STCIH2A

- GE IS200TCCVH1B (Mark VIe CPU Module): The central processing unit for the Mark VIe system, working alongside the IS200STCIH2A to execute control algorithms.

- GE IS200TBVCH1A (Turbine Speed Control Module): Specialized for speed regulation, complementing the IS200STCIH2A in complex turbine control setups.

- GE IS200DSVIH1A (Discrete Signal Interface Module): Extends the I/O capabilities of the Mark VIe system, integrating with the IS200STCIH2A for enhanced discrete signal processing.

- GE IS200ALGCH2A (Analog Logic Module): Performs advanced analog signal processing, often used in conjunction with the IS200STCIH2A for complex control strategies.

- GE IS200PWRCH1A (Power Supply Module): Provides redundant power to the Mark VIe system, ensuring stable operation for the IS200STCIH2A and other modules.

- GE IS200COMMH1A (Communication Module): Enhances network connectivity for the Mark VIe system, supporting Ethernet/IP and OPC UA protocols with the IS200STCIH2A.

Installation and Maintenance: GE IS200STCIH2A

Pre-installation Preparations:

Before installing the IS200STCIH2A, verify the control cabinet is properly grounded and ventilated to meet the module’s thermal requirements. Ensure the 24V DC power supply matches specifications and that all tools (e.g., torque screwdrivers) are available. Mount the module in the Mark VIe rack using the provided brackets, leaving adequate space for heat dissipation. Connect power cables to the terminal block, following GE’s wiring diagrams, and establish communication links using shielded cables to minimize interference.

Before installing the IS200STCIH2A, verify the control cabinet is properly grounded and ventilated to meet the module’s thermal requirements. Ensure the 24V DC power supply matches specifications and that all tools (e.g., torque screwdrivers) are available. Mount the module in the Mark VIe rack using the provided brackets, leaving adequate space for heat dissipation. Connect power cables to the terminal block, following GE’s wiring diagrams, and establish communication links using shielded cables to minimize interference.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks for loose connections, damaged cables, or overheating. Clean the module’s vents with compressed air to prevent dust accumulation.

- Functional Testing: Quarterly tests of I/O channels using a calibrated signal source to ensure accuracy. Use GE’s Proficy software to verify communication integrity and module health.

- Firmware Updates: Periodically update firmware via the Mark VIe system interface to access new features and security patches, ensuring compatibility with evolving control protocols.

- Spare Parts Management: Maintain a spare IS200STCIH2A on site, leveraging our global supply chain for quick replacement of discontinued or urgent components.

Product Guarantee: GE IS200STCIH2A

Our company provides a 12-month quality warranty for the GE IS200STCIH2A turbine control interface module, covering hardware defects from non-human causes. During the warranty period, we will replace any module with abnormal signal processing, communication failures, or physical damage at no cost. For discontinued models or urgent needs, our extensive inventory and global logistics network ensure prompt fulfillment, minimizing downtime and supporting continuous industrial operation.

With 17 years of expertise in industrial control distribution, we are committed to reliable products and exceptional service. The IS200STCIH2A exemplifies our dedication to quality, offering precise turbine control for critical infrastructure. Contact us today to optimize your power generation systems with this advanced interface module.

Note: All product names, logos, and brands are property of their owners. This document is informational and does not substitute for GE’s official technical manuals.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

GE IS200SDIIH1ADB MRP683026 base

GE IS200SPIDG1ABA exchange

GE IS200SPROH1AAB MRP663860 DI module

GE IC697BME731 Control system power supply

GE IC697CHS770 Pressure transmitter

GE IS200TRPGH1BDD S1C5029 Servo drive

GE IS200TTURH1CCC S1DF00Z Eddy current sensor

GE IS200TRLYH1BGF monitor

GE CK11CE300 Safety system

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: