Description

GE IS200STAOH2AAA Product Specification

Product Overview

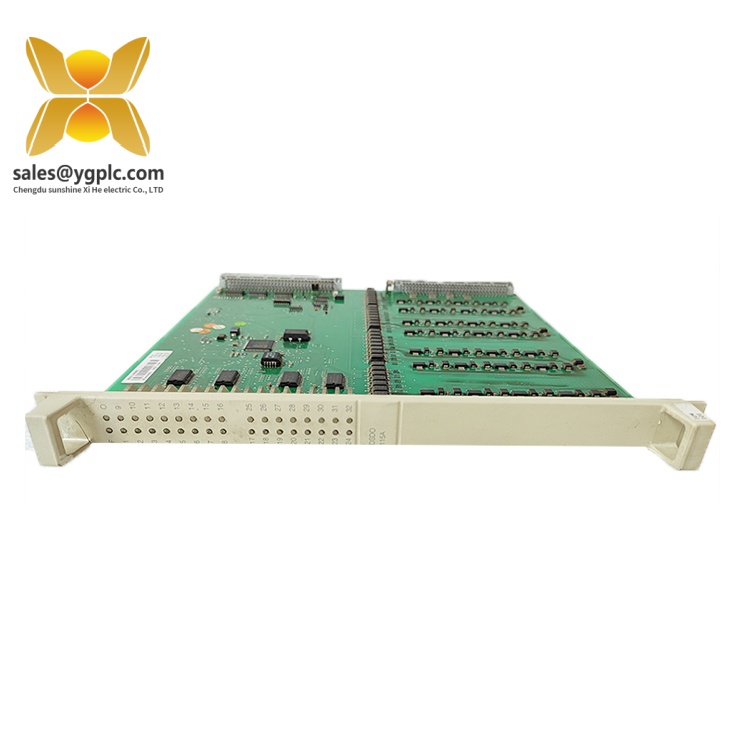

The GE IS200STAOH2AAA is a high-precision synchronizer module designed for GE’s Mark VIe Series of gas turbine control systems, serving as a critical component in industrial automation for power generation and energy production. Engineered to ensure seamless synchronization of gas turbines with electrical grids, the GE IS200STAOH2AAA monitors and adjusts turbine speed and voltage to match grid parameters, minimizing transient stresses and ensuring stable power output. As part of GE’s advanced control platform, this module integrates with other Mark VIe components to form a comprehensive turbine management system, essential for industries requiring reliable power generation such as utilities, oil and gas, and manufacturing.

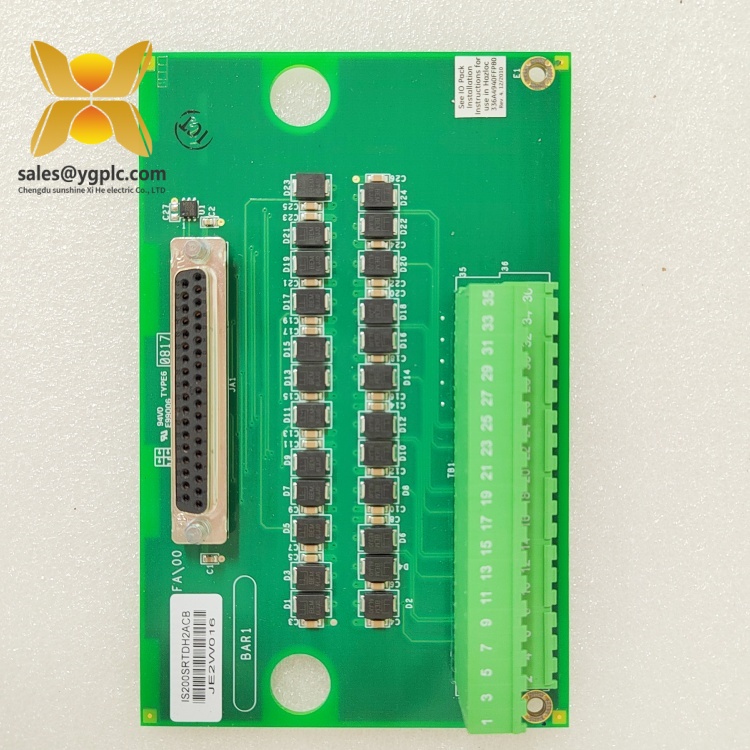

The GE IS200STAOH2AAA features the latest digital signal processing (DSP) technology, enabling real-time analysis of grid frequency, voltage magnitude, and phase angle. It supports multiple input channels for voltage and current signals, with configurable alarm thresholds and protection functions to prevent grid instability. The module’s compact design (203 mm × 140 mm × 76 mm) and rugged construction make it suitable for harsh industrial environments, while its hot-swappable design allows maintenance without system shutdowns. With built-in Ethernet and serial communication interfaces, the GE IS200STAOH2AAA facilitates seamless integration with supervisory control and data acquisition (SCADA) systems, enhancing operational visibility and control.

In automation systems, the GE IS200STAOH2AAA acts as a bridge between the gas turbine and the electrical grid, ensuring safe and efficient synchronization. Its advanced algorithms calculate the optimal moment for closing the generator breaker, reducing mechanical stress on the turbine and improving grid stability. By combining precision control with robust reliability, the module helps power plants maximize energy production, minimize downtime, and comply with strict grid interconnection standards.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200STAOH2AAA |

| Manufacturer | General Electric (GE) |

| Product Type | Synchronizer Module (Gas Turbine Control) |

| Input Voltage | 120 VAC ±10% (nominal), 24 VDC ±10% |

| Frequency Range | 45–65 Hz |

| Communication Interfaces | Ethernet (10/100BaseT), RS-485, RS-232 |

| Input Channels | 8 analog (voltage/current), 16 digital |

| Output Signals | Relay contacts, analog (4–20 mA, 0–10 VDC) |

| Physical Dimensions | 203 mm (W) × 140 mm (H) × 76 mm (D) |

| Weight | 1.8 kg |

| Operating Temperature | 0°C to +55°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, ISO 9001 |

Main Features and Advantages

Precision Synchronization Capability: The GE IS200STAOH2AAA utilizes advanced DSP algorithms to achieve synchronization within 1% of grid frequency, minimizing transient currents and mechanical stress during generator connection. This precision is critical for maintaining grid stability in power plants and industrial microgrids.

Multi-Channel Data Acquisition: With 8 analog and 16 digital input channels, the module monitors multiple parameters simultaneously, including voltage, current, frequency, and phase angle. This comprehensive data collection enables real-time adjustments to turbine operation for optimal grid compatibility.

Rugged Industrial Design: Built with a metal enclosure and conformal-coated PCBs, the GE IS200STAOH2AAA withstands harsh environments, including high temperatures, humidity, and electromagnetic interference (EMI). Its wide operating temperature range ensures reliable performance in both indoor and outdoor installations.

Hot-Swap Functionality: The module’s hot-swappable design allows replacement without powering down the control system, reducing maintenance downtime in critical power generation applications. This feature is invaluable for 24/7 operational settings.

Seamless System Integration: Compatible with GE’s Mark VIe platform and industry-standard communication protocols (Ethernet/IP, Modbus), the GE IS200STAOH2AAA integrates effortlessly with existing SCADA and PLC systems. This interoperability simplifies system expansion and upgrades.

Application Areas

The GE IS200STAOH2AAA is essential in industries where reliable power generation and grid synchronization are critical:

-

Power Generation:

- Synchronizes gas turbines with utility grids in combined cycle power plants, ensuring stable energy delivery.

- Enables microgrid operations in remote locations, allowing seamless transition between on-site generation and grid connection.

-

Oil and Gas:

- Controls power generation in offshore platforms and refineries, where stable power is essential for critical processes like pumping and compression.

- Supports emergency power systems in oil fields, ensuring continuous operation during grid outages.

-

Manufacturing:

- Maintains power quality in industrial facilities with high-energy demand, such as automotive plants and semiconductor factories.

- Enables uninterruptible power supply (UPS) systems for sensitive manufacturing equipment, reducing production losses.

-

Renewable Energy:

- Integrates gas turbines with renewable energy grids, providing backup power during intermittent renewable generation (e.g., wind or solar).

- Optimizes power output in combined heat and power (CHP) systems, enhancing energy efficiency in commercial and industrial buildings.

Related Products

- GE IS200STAHH1BAA: A higher-voltage variant of the synchronizer module, suitable for large-scale power plants.

- GE IS200STAIH1AAA: A predecessor model with similar functionality, often used in legacy Mark VI systems.

- GE IS200TCCPH1AAA: A turbine control processor module that pairs with the GE IS200STAOH2AAA for comprehensive turbine management.

- GE IS200DSVOH1AAA: A drive control module that coordinates with the synchronizer to adjust turbine speed during synchronization.

- GE IS200PWRHH2AAA: A power supply module that ensures stable power for the GE IS200STAOH2AAA in redundant configurations.

- GE IS200EXCHH1AAA: A communication gateway module that enables data exchange between the synchronizer and remote monitoring systems.

Installation and Maintenance

Pre-installation Preparation:

Before installing the GE IS200STAOH2AAA, ensure the following:

Before installing the GE IS200STAOH2AAA, ensure the following:

- Verify the power supply matches the module’s requirements (120 VAC or 24 VDC) and that the control cabinet is properly grounded to prevent ESD damage.

- Use GE’s Proficy software to configure communication parameters (IP address, baud rate) and define synchronization thresholds based on grid specifications.

- Mount the module in a 19″ rack with at least 25 mm of clearance for airflow, securing it with the provided brackets to minimize vibration.

Maintenance Recommendations:

- Routine Checks: Monthly visual inspections of front-panel LEDs (green for normal operation, red for faults) and cleaning dust from ventilation slots.

- Calibration: Annual calibration of voltage and current inputs using certified test equipment to ensure measurement accuracy.

- Firmware Updates: Periodically update the module’s firmware via GE’s online portal to access bug fixes and new features.

- Functional Testing: Biannual synchronization simulations to verify breaker closure timing and alarm responses, ensuring compliance with grid standards.

Product Warranty

Our company provides a one-year quality warranty for the GE IS200STAOH2AAA, covering hardware failures due to non-human factors. During the warranty period, we will replace any module that exhibits abnormal synchronization performance or functional defects. For discontinued models like the GE IS200STAOH2AAA, our global inventory of legacy industrial parts ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support and repair services, including firmware updates and component-level repairs, to maintain your system’s reliability over its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data from GE’s official specifications and industry applications. For detailed installation guides, refer to the GE IS200STAOH2AAA user manual or contact our technical support team.

GE IS200JPDDG1AAA regulator

GE IS200PMCIH1AAA6BA00 I/O board

GE IS200PMCIH1ABA Power strip

GE IS200SAMBH1ABA Power source

GE IC697CHS790 Main frame

GE IC697ALG320 Digital output module 24VDC

GE IC697ALG440 Output module

GE IC697BEM711 Output module

GE IC695ALG508-AA DCS card module

GE IC695CPU315-BB Data acquisition module

GE IC695CPU315-CD probe

GE IC695CRU320 Tachometer sensor

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: