Description

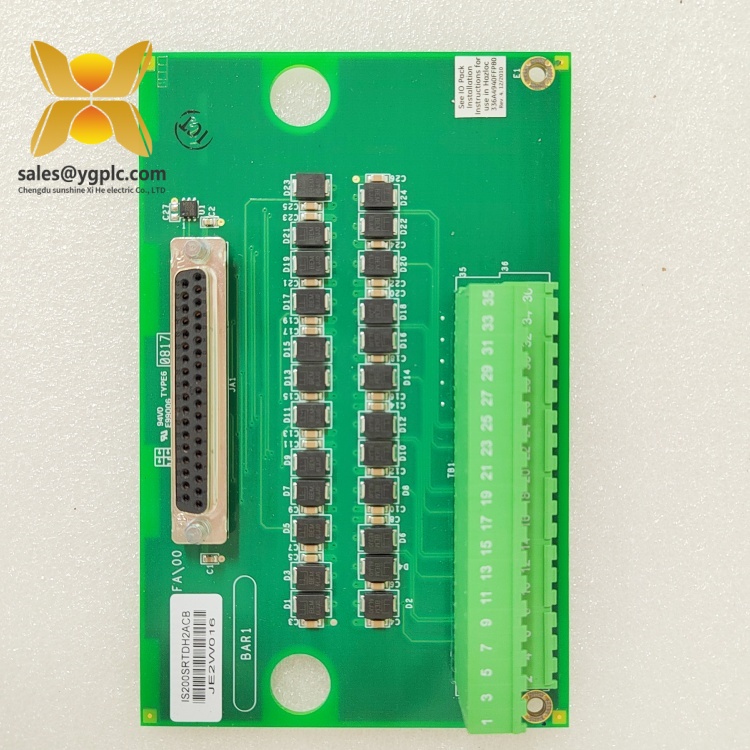

GE IS200SRTDH2ACB Mark VIe RTD Input Module

Product Overview

The GE IS200SRTDH2ACB is a high-precision RTD Input Module designed for industrial temperature monitoring within GE’s Mark VIe distributed control system (DCS). Engineered to convert resistance signals from thermal sensors into digital data, this module serves as a critical component in power generation, oil & gas, and manufacturing ecosystems where accurate temperature measurement is essential for process stability and equipment protection. The IS200SRTDH2ACB integrates seamlessly with other Mark VIe modules (e.g., analog output modules, controller units), enabling real-time temperature monitoring in harsh industrial environments.

Featuring a rugged industrial design, the GE IS200SRTDH2ACB supports multiple RTD types (e.g., Pt100, Ni100) with configurable input ranges, ensuring compatibility with diverse temperature sensing applications. Its advanced signal conditioning circuitry provides ±0.1% full-scale accuracy and built-in linearization, eliminating the need for external calibration. The module’s hot-swappable design allows replacement without system shutdown, minimizing downtime during maintenance, while its wide operating temperature range (-40°C to +85°C) ensures reliable performance in extreme conditions. As part of the IS200 Series, the IS200SRTDH2ACB bridges field-mounted RTD sensors with the Mark VIe control platform, enabling precise temperature data acquisition for critical processes like turbine casing monitoring or chemical reactor control.

In automation systems, the IS200SRTDH2ACB acts as the interface between temperature sensors and the DCS, converting resistance changes into standardized 4–20 mA or digital signals. Its 16-channel configuration supports high-density temperature monitoring, while galvanic isolation between channels prevents ground loops and ensures signal integrity. By delivering reliable temperature data to the control layer, this module enhances process efficiency, reduces energy consumption, and prevents equipment damage from overheating, making it indispensable for industries requiring continuous thermal management.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200SRTDH2ACB |

| Manufacturer | GE |

| Product Type | RTD Input Module |

| Platform | Mark VIe |

| Input Channels | 16 isolated channels |

| RTD Types | Pt100, Ni100, Cu100 (configurable) |

| Measurement Range | -200°C to +850°C (depending on RTD type) |

| Accuracy | ±0.1% of full scale |

| Resolution | 16-bit |

| Output Signal | 4–20 mA, RS-485 (Modbus RTU) |

| Power Supply | 24 V DC ±10% (from Mark VIe rack) |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted in Mark VIe enclosure |

Key Features and Advantages

High-Precision Temperature Sensing: The IS200SRTDH2ACB ensures accurate temperature measurement with ±0.1% full-scale accuracy, critical for processes where thermal variations impact product quality or equipment safety, such as turbine blade temperature monitoring in power plants.

Multi-RTD Compatibility: Supporting Pt100, Ni100, and Cu100 sensors, the module adapts to diverse industrial setups, eliminating the need for specialized modules and reducing inventory complexity.

Galvanic Isolation: Each channel features 250 V RMS galvanic isolation, preventing ground loops and electromagnetic interference, which is essential in high-noise environments like manufacturing floors or substations.

Hot-Swap Capability: The module can be replaced without powering down the system, enabling maintenance during operation and minimizing production interruptions in 24/7 industrial settings.

Wide Environmental Tolerance: Engineered to withstand -40°C to +85°C, the IS200SRTDH2ACB performs reliably in extreme temperatures, making it suitable for outdoor installations or high-heat zones like furnace environments.

Advanced Diagnostics: Built-in self-test functions monitor channel health, open/short circuit detection, and temperature drift, providing real-time alerts to maintenance teams and reducing troubleshooting time.

Application Areas

The GE IS200SRTDH2ACB is deployed in industries requiring precise temperature control and monitoring:

- Power Generation: Monitors stator and rotor temperatures in generators, steam turbine casings, and transformer oil, ensuring optimal performance and preventing overheating failures.

- Oil & Gas: Measures process temperatures in refinery reactors, pipeline flow stations, and offshore platforms, supporting efficient hydrocarbon processing and safety compliance.

- Chemical Processing: Controls temperature in reaction vessels, distillation columns, and heat exchangers, maintaining process consistency and preventing thermal runaway in chemical synthesis.

- Manufacturing: Monitors oven and kiln temperatures in ceramic, glass, and metal processing, ensuring product quality and equipment longevity.

- Water/Wastewater Treatment: Measures water temperature in treatment plants to optimize chemical dosing and biological process efficiency.

Specific applications include:

- Turbine Health Monitoring: Integrates with RTDs on turbine bearings and exhaust systems to detect early signs of overheating, enabling proactive maintenance.

- Process Heating Control: Provides real-time temperature data for PID controllers in industrial furnaces, ensuring uniform heating and energy efficiency.

- Environmental Chamber Monitoring: Maintains precise temperature control in testing facilities for aerospace or automotive component validation.

Related Products

- IS200AASAH2AD (Analog Output Module): Works with the IS200SRTDH2ACB to send temperature control signals to actuators, forming a closed-loop system.

- IS200TCTGG1A (Turbine Control Module): Processes temperature data from the IS200SRTDH2ACB for turbine speed and load regulation.

- IS200PWRCH2AA (Power Supply Module): Ensures redundant power for the IS200SRTDH2ACB in mission-critical setups.

- IS200TBCHH1AA (Terminal Block Module): Simplifies field wiring for RTD connections to the IS200SRTDH2ACB, reducing installation errors.

- IS200COMMH1AA (Communication Module): Enables Ethernet connectivity for the IS200SRTDH2ACB, supporting remote temperature data access.

- IS200ALGH2AA (Algorithm Module): Executes temperature-based control logic using data from the IS200SRTDH2ACB for complex processes.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE IS200SRTDH2ACB, verify the Mark VIe rack is grounded and ventilated. Ensure the power supply (24 V DC) matches module requirements and route shielded cables for RTD connections, keeping them separate from high-voltage lines to minimize interference. Use GE’s Proficy software to configure channel settings (e.g., RTD type, alarm thresholds) and assign unique addresses for each channel. Mount the module in the rack, securing it with captive screws to prevent vibration-induced loosening.

Before installing the GE IS200SRTDH2ACB, verify the Mark VIe rack is grounded and ventilated. Ensure the power supply (24 V DC) matches module requirements and route shielded cables for RTD connections, keeping them separate from high-voltage lines to minimize interference. Use GE’s Proficy software to configure channel settings (e.g., RTD type, alarm thresholds) and assign unique addresses for each channel. Mount the module in the rack, securing it with captive screws to prevent vibration-induced loosening.

Maintenance Suggestions:

- Routine Checks: Monthly visual inspections of LED indicators to confirm power and communication status. Use Proficy software to review channel diagnostics for abnormal readings or fault codes.

- Calibration: Annually calibrate the IS200SRTDH2ACB using a precision temperature source to maintain accuracy. Compare module readings against a reference thermometer and adjust offsets as needed.

- Environmental Management: Quarterly cleaning of module vents to prevent dust accumulation, especially in dusty environments. Ensure the control room temperature stays within -40°C to +85°C for optimal performance.

- Spare Parts Management: Store spare IS200SRTDH2ACB modules in anti-static packaging at room temperature, rotating inventory to ensure shelf-life viability. Test spares periodically to validate functionality.

Product Guarantee

Our company provides a 12-month quality warranty for the GE IS200SRTDH2ACB, covering hardware defects under normal operation. In the event of measurement inaccuracies or module failures, we offer prompt replacement services to minimize downtime. For legacy or urgent needs, our global supply chain ensures rapid delivery of the IS200SRTDH2ACB and related spares. Our technical support team assists with installation, calibration, and troubleshooting, delivering reliable solutions to maintain your temperature monitoring systems.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IC660EBD025 Communication output interface component

GE IC660ELB912 Interface component

GE IC660ELB912G DCS card module

GE IC697CPX928-FE Integrated protection device

GE IC697CPX935 Connecting module

GE IC697MDL652 driver

GE IC697MDL653 servo

GE IC697MDL671 Eddy current sensor

GE IC695CPU315-CD probe

GE IC695CRU320 Tachometer sensor

GE IC695CRU320-BB modbus card

GE IC695CRU320CA-EL Power strip

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: