Description

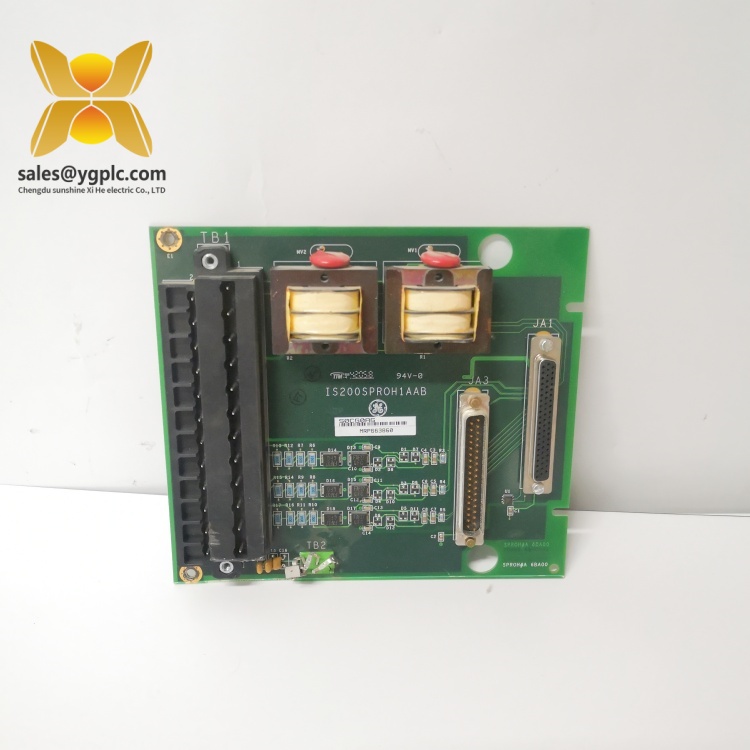

GE IS200SPROH1AAB MRP663860 Turbine Protection Relay Module

Product Overview: GE IS200SPROH1AAB MRP663860

The GE IS200SPROH1AAB MRP663860 turbine protection relay module is a high-reliability industrial control component designed for GE’s Mark VIe Turbine Control System, a cornerstone of advanced turbine management in power generation and process industries. Engineered to safeguard steam and gas turbines from catastrophic failures, this module serves as a critical safety component, monitoring key parameters and triggering protective actions to prevent damage from overspeed, vibration, or process anomalies. The IS200SPROH1AAB MRP663860 integrates seamlessly with GE’s Mark VIe platform, combining robust hardware with precise logic processing to ensure operational safety and efficiency.

Featuring dual redundant power supplies and fail-safe design principles, the IS200SPROH1AAB MRP663860 processes input signals from sensors monitoring turbine speed, vibration, and temperature, comparing them against predefined thresholds. Its solid-state relay outputs enable rapid shutdown or alarm activation, while the built-in self-diagnostic functions continuously verify component health, reducing unplanned downtime. The module’s -40°C to +70°C operating range and IP20 protection rating make it suitable for harsh industrial environments, including power plants, refineries, and manufacturing facilities.

As a key element of GE’s turbine control ecosystem, the IS200SPROH1AAB MRP663860 enhances system reliability by providing redundant protection layers. Its compatibility with Mark VIe racks (e.g., IS200RACK1A) and communication protocols like Modbus ensures seamless integration into distributed control systems (DCS), supporting real-time monitoring and remote diagnostics. By combining precision protection with rugged durability, this module delivers tangible value through minimized maintenance costs and extended turbine lifespan.

Technical Specifications: GE IS200SPROH1AAB MRP663860

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200SPROH1AAB MRP663860 |

| Manufacturer | GE |

| Product Type | Turbine Protection Relay Module |

| Input Voltage | 24V DC (dual redundant) |

| Input Channels | 8 digital inputs, 4 analog inputs |

| Output Signals | 6 solid-state relays (5A/250V AC max) |

| Communication Protocol | Modbus RTU/TCP, Ethernet (optional) |

| Physical Dimensions | 177.8 mm (H) × 101.6 mm (W) × 254 mm (D) |

| Weight | 2.3 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | Rack-mounted (Mark VIe compatible) |

| Compliance | IEEE 1451, IEC 61508 (SIL 2 capable) |

| Country of Origin | United States |

Main Features and Advantages: GE IS200SPROH1AAB MRP663860

Dual Redundancy for Mission-Critical Safety: The IS200SPROH1AAB MRP663860 incorporates dual power supplies and redundant signal processing, ensuring continuous operation even during single-point failures. This design is critical for preventing turbine shutdowns due to power anomalies or component malfunctions.

Precision Protection Logic: The module’s advanced algorithms analyze real-time data from multiple sensors, enabling rapid response to deviations from safe operating parameters. Its configurable trip thresholds and time delays allow customization to match specific turbine characteristics, enhancing protection accuracy.

Robust Industrial Design: Built with rugged metal enclosures and thermal management systems, the module withstands high vibration, temperature fluctuations, and electromagnetic interference typical of turbine environments. Its IP20 rating protects against dust and accidental contact, ensuring long-term reliability.

Seamless System Integration: Compatible with GE’s Mark VIe control platform, the IS200SPROH1AAB MRP663860 integrates effortlessly with existing DCS and SCADA systems. Its Modbus connectivity enables remote monitoring and configuration, reducing maintenance overhead for large-scale installations.

Advanced Diagnostics and Reporting: The module’s built-in diagnostics provide real-time status updates and fault logging, simplifying troubleshooting. LED indicators and serial communication interfaces offer immediate visibility into operational health, minimizing mean time to repair (MTTR).

Application Areas: GE IS200SPROH1AAB MRP663860

The GE IS200SPROH1AAB MRP663860 turbine protection relay module is essential for industries relying on critical turbine operations:

- Power Generation: Installed in thermal, combined-cycle, and renewable energy plants to protect steam and gas turbines from overspeed, overspeed, or lubrication failures. The module ensures grid stability by preventing unplanned outages in power-generating equipment.

- Oil and Gas: Deployed in refineries and pipeline compressor stations to safeguard turbines driving pumps and compressors. Its rugged design withstands harsh offshore and onshore environments, including exposure to corrosive elements.

- Industrial Manufacturing: Used in facilities where turbines drive mechanical processes, such as paper mills, chemical plants, and cement production. The module’s precise protection reduces downtime and maintenance costs in continuous production settings.

- Marine and Aerospace: Integrated into marine propulsion systems and aircraft ground support equipment, ensuring safe turbine operation in mobile and remote applications with fluctuating operational demands.

Related Products: GE IS200SPROH1AAB MRP663860

- GE IS200TURBH1AAA Turbine Control Module: A core control module for Mark VIe systems, working alongside the IS200SPROH1AAB MRP663860 to manage turbine speed and load.

- GE IS200VIBBH1B Vibration Monitoring Module: Supplies vibration data to the IS200SPROH1AAB MRP663860, enabling comprehensive machinery health assessment.

- GE IS200RACK1A Mark VIe Rack Enclosure: Houses the IS200SPROH1AAB MRP663860 and other modules, providing power distribution and mechanical support.

- GE IS200PWRCH1A Power Supply Module: Provides redundant power to the rack, ensuring stable operation for the IS200SPROH1AAB MRP663860.

- GE IS200COMMH1A Communication Module: Enables Ethernet connectivity for the IS200SPROH1AAB MRP663860, facilitating remote monitoring via SCADA systems.

- GE IS200SPEEDH1A Speed Monitoring Module: Specialized for turbine speed measurement, feeding critical data to the IS200SPROH1AAB MRP663860 for overspeed protection.

Installation and Maintenance: GE IS200SPROH1AAB MRP663860

Pre-installation Preparations:

Before installing the IS200SPROH1AAB MRP663860, verify the control rack is properly grounded and powered (24V DC). Clean the rack slot and align the module with the guides, securing it with retention brackets. Connect sensor inputs (speed, vibration, temperature) to the designated terminals, ensuring shielded wiring to minimize EMI. Configure trip thresholds and communication parameters using GE’s Proficy Machine Edition software, testing signal integrity before commissioning.

Before installing the IS200SPROH1AAB MRP663860, verify the control rack is properly grounded and powered (24V DC). Clean the rack slot and align the module with the guides, securing it with retention brackets. Connect sensor inputs (speed, vibration, temperature) to the designated terminals, ensuring shielded wiring to minimize EMI. Configure trip thresholds and communication parameters using GE’s Proficy Machine Edition software, testing signal integrity before commissioning.

Maintenance Recommendations:

- Routine Inspections: Monthly visual checks for loose connections, overheating, or damaged cables. Use the module’s LED indicators to verify power, communication, and fault status.

- Functional Testing: Quarterly simulate fault conditions (e.g., overspeed) to ensure relay activation and trip response. Calibrate input sensors (e.g., speed probes) to maintain measurement accuracy.

- Firmware Updates: Periodically update firmware via the communication interface to access new protection algorithms and bug fixes, as provided by GE’s support resources.

- Spare Parts Management: Keep a spare IS200SPROH1AAB MRP663860 on hand, leveraging our global supply chain for rapid replacement of discontinued or urgent components.

Product Guarantee: GE IS200SPROH1AAB MRP663860

Our company provides a 12-month quality warranty for the GE IS200SPROH1AAB MRP663860 turbine protection relay module, covering non-human-induced hardware defects. During the warranty period, we will replace any module with relay failures, communication issues, or physical damage at no cost. For urgent needs or discontinued models, our extensive inventory and global logistics network ensure prompt fulfillment, minimizing downtime and supporting continuous operation of your turbine systems.

With 17 years of expertise in industrial control distribution, we are committed to delivering reliable products and exceptional service. The IS200SPROH1AAB MRP663860 exemplifies our dedication to quality, offering robust turbine protection for critical infrastructure. Contact us today to optimize your turbine safety with this advanced relay module.

Note: All product names, logos, and brands are property of their owners. This document is informational and does not substitute for GE’s official technical manuals.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

GE IS200ISBBG2AAB Interface component

GE IS200JPDDG1AAA DCS card module

GE IS200PMCIH1AAA6BA00 Data acquisition module

GE IS200PMCIH1ABA probe

GE IS200SAMBH1ABA | Sensor Interface Module for Mark VIe Turbine Control System | IS200STCIH2A

GE CK11CE300 Safety system

GE IC695CPE400-ABAB Distributed control

GE IS420UCSBH3A Terminal panel

GE IC670MDL640 System

GE IC670MDL644 DCS

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: