Description

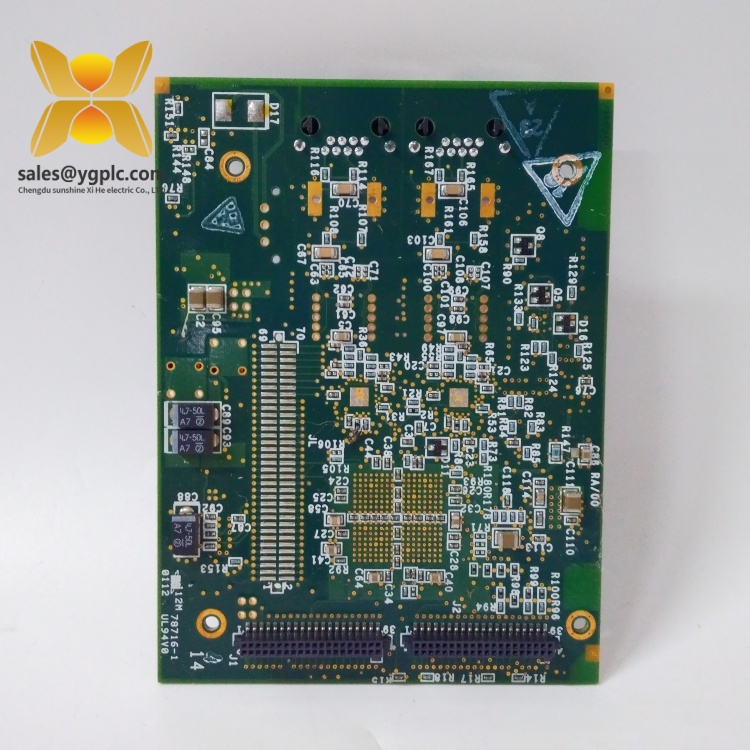

GE IS200HSLAH2ADE Mark VIe High-Speed Linear Actuator Module

Product Overview

The GE IS200HSLAH2ADE is a high-performance High-Speed Linear Actuator Module designed as a critical component of GE’s Mark VIe distributed control system (DCS), specializing in precise motion control for industrial automation applications. Engineered to convert electrical control signals into linear mechanical movements, this module serves as the interface between the control system and field actuators in turbines, compressors, and process valves. As part of the IS200 Series, the IS200HSLAH2ADE integrates seamlessly with other Mark VIe components (e.g., control processors, I/O modules), enabling deterministic control in power generation, oil & gas, and manufacturing sectors where precision and reliability are non-negotiable.

Featuring a rugged industrial design, the GE IS200HSLAH2ADE supports high-speed actuation with positioning accuracy within ±0.1% of full stroke, ensuring seamless operation of critical valves and dampers. Its dual-core processor architecture allows real-time feedback processing from position sensors, while built-in redundancy mechanisms (electrical and mechanical) minimize the risk of single-point failures. The module’s compatibility with GE’s Proficy software suite enables remote configuration, diagnostics, and predictive maintenance, reducing downtime and enhancing system efficiency. With a wide operating temperature range (-40°C to +70°C) and compliance with industry standards (e.g., API 670), the IS200HSLAH2ADE delivers consistent performance in harsh environments, including high vibration and electromagnetic interference.

In automation ecosystems, the IS200HSLAH2ADE bridges the gap between control logic and physical actuation, translating digital commands into precise linear movements for process control. Its modular design facilitates easy integration into existing Mark VIe systems, while advanced self-diagnostic features (e.g., motor health monitoring, position feedback validation) provide real-time insights into component status. By combining high-speed response with robust fault tolerance, this module enhances the safety, efficiency, and sustainability of industrial processes worldwide.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200HSLAH2ADE |

| Manufacturer | GE |

| Product Type | High-Speed Linear Actuator Module |

| Platform | Mark VIe |

| Actuation Range | 0–100 mm (customizable) |

| Speed | Up to 25 mm/sec |

| Position Accuracy | ±0.1% of full stroke |

| Input Voltage | 24 V DC ±10% (control); 100–240 V AC (motor) |

| Output Force | Up to 5000 N |

| Physical Dimensions | 305 mm (H) × 229 mm (W) × 127 mm (D) |

| Weight | 7.5 kg |

| Communication | Profibus DP, Ethernet/IP (via adapter) |

| Operating Temperature | -40°C to +70°C |

| Mounting | Flange-mounted or rack-integrated |

Key Features and Advantages

High-Speed Precision Control: The IS200HSLAH2ADE delivers rapid actuation with sub-millimeter accuracy, critical for applications requiring fast response times, such as turbine valve control during load changes or emergency shutdowns. Its dynamic braking system ensures smooth stops and prevents overshoot, minimizing mechanical stress.

Dual Redundancy Architecture: Electrical redundancy in power supplies and communication paths, combined with mechanical backup systems, ensures continuous operation during component failures. This design meets SIL 2 safety integrity requirements for critical processes.

Advanced Feedback Integration: Built-in linear variable differential transformers (LVDTs) provide real-time position feedback, enabling closed-loop control and eliminating the need for external sensors. This integration reduces wiring complexity and enhances system reliability.

Rugged Industrial Design: The module’s hermetically sealed enclosure and corrosion-resistant materials protect against dust, moisture, and corrosive gases, making it suitable for offshore platforms, refineries, and other harsh environments. Its vibration resistance (up to 50 g) ensures stable operation in high-motion settings.

Modular and Scalable: As part of the Mark VIe ecosystem, the IS200HSLAH2ADE supports hot-swappable installation, allowing maintenance without system shutdown. Its standardized interface enables easy replacement or upgrade, future-proofing industrial investments.

Comprehensive Diagnostics: Real-time monitoring of motor temperature, gear wear, and position accuracy via the Mark VIe rack interface allows proactive maintenance. Alarms and fault codes are transmitted to the control system, reducing mean time to repair (MTTR).

Application Areas

The GE IS200HSLAH2ADE is strategically deployed in industries requiring precise linear motion control:

- Power Generation: Controls steam turbine inlet valves, generator excitation systems, and condenser dampers in thermal and renewable energy plants, ensuring stable power output and grid synchronization.

- Oil & Gas: Manages pipeline control valves, compressor anti-surge valves, and wellhead actuators in upstream, midstream, and downstream operations, optimizing flow rates and preventing overpressure.

- Chemical Processing: Regulates process valves in reactors, distillation columns, and mixing systems, maintaining precise chemical ratios and preventing process upsets.

- Marine Propulsion: Drives rudder and thruster control systems in large vessels, enabling responsive maneuvering and compliance with maritime safety standards.

Specific applications include:

- Turbine Governor Control: Rapid adjustment of steam valves to maintain speed during load fluctuations, critical for grid stability in power plants.

- Emergency Shutdown Systems (ESD): Fast-acting actuation of isolation valves in hazardous environments, minimizing the impact of process upsets.

- Precision Process Control: Accurate positioning of control valves in chemical plants to maintain optimal temperature, pressure, and flow rates.

Related Products

- IS200TCTGG1A (Turbine Control Module): Works in tandem with the IS200HSLAH2ADE to provide control logic for turbine valve actuation.

- IS200AAHAH2ADC (Analog Input Module): Acquires sensor data for feedback, complementing the IS200HSLAH2ADE in closed-loop control systems.

- IS200PWR (Power Supply Module): Provides redundant power to the IS200HSLAH2ADE and other Mark VIe modules, ensuring uninterrupted operation.

- IS200TBCH (Terminal Block Module): Simplifies field wiring for the IS200HSLAH2ADE, reducing installation time and errors.

- IS200COMM (Communication Module): Enables remote monitoring of the IS200HSLAH2ADE via Ethernet, supporting Industry 4.0 initiatives.

- IS200ALG (Algorithm Module): Executes advanced control algorithms for the IS200HSLAH2ADE in complex process scenarios.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE IS200HSLAH2ADE, verify the mounting surface is flat and properly grounded. Ensure power supplies (24 V DC control, 100–240 V AC motor) match specifications and route shielded cables separately from high-voltage lines to minimize interference. Use GE’s Proficy software to configure actuation parameters (stroke range, speed limits, alarm thresholds) and validate compatibility with existing Mark VIe components. Mount the module using anti-vibration brackets to reduce mechanical stress in high-vibration environments.

Before installing the GE IS200HSLAH2ADE, verify the mounting surface is flat and properly grounded. Ensure power supplies (24 V DC control, 100–240 V AC motor) match specifications and route shielded cables separately from high-voltage lines to minimize interference. Use GE’s Proficy software to configure actuation parameters (stroke range, speed limits, alarm thresholds) and validate compatibility with existing Mark VIe components. Mount the module using anti-vibration brackets to reduce mechanical stress in high-vibration environments.

Maintenance Suggestions:

- Routine Inspections: Monthly visual checks for loose connections, wear on mechanical components, and overheating signs. Use Proficy to review actuation logs for 异常 (abnormal) patterns.

- Lubrication and Calibration: Annually lubricate moving parts and calibrate LVDT feedback using a precision gauge to maintain positioning accuracy. Document calibration results for compliance.

- Redundancy Testing: Simulate single-point failures (e.g., power loss, communication disruption) to verify redundant systems function correctly, ensuring failover capability.

- Spare Parts Management: Store spare IS200HSLAH2ADE modules in a temperature-controlled environment (20–25°C, <50% humidity) and test them quarterly to ensure functionality.

Product Guarantee

Our company provides a 12-month quality warranty for the GE IS200HSLAH2ADE, covering hardware defects under normal use. In the event of actuation anomalies or functional failures, we offer prompt replacement services to minimize downtime. For legacy or urgent requirements, our global supply chain ensures rapid delivery of the IS200HSLAH2ADE and related components. Our technical support team assists with installation, calibration, and troubleshooting, delivering reliable solutions to maintain your system’s precision and reliability.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IS200TRLYH1BHH System-wide spare parts

GE IS200EPMCH1 ITCC controller

GE IS215UCCCM04A Fault tolerant control system

GE IS215UCCCM04AB Digital input module

GE IS220PTURH1A Safety system module

GE IC670ALG310-JA Remote extender module

GE IC697MDL750 DCS spare parts

GE IC697MEM717C PLC central processing unit

GE IC697PWR720 DO module

GE IC697PWR724 Control processor

GE IC697PWR748 Switch quantity input card

GE IC697VDD100 Enhanced intelligent communication module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: