Description

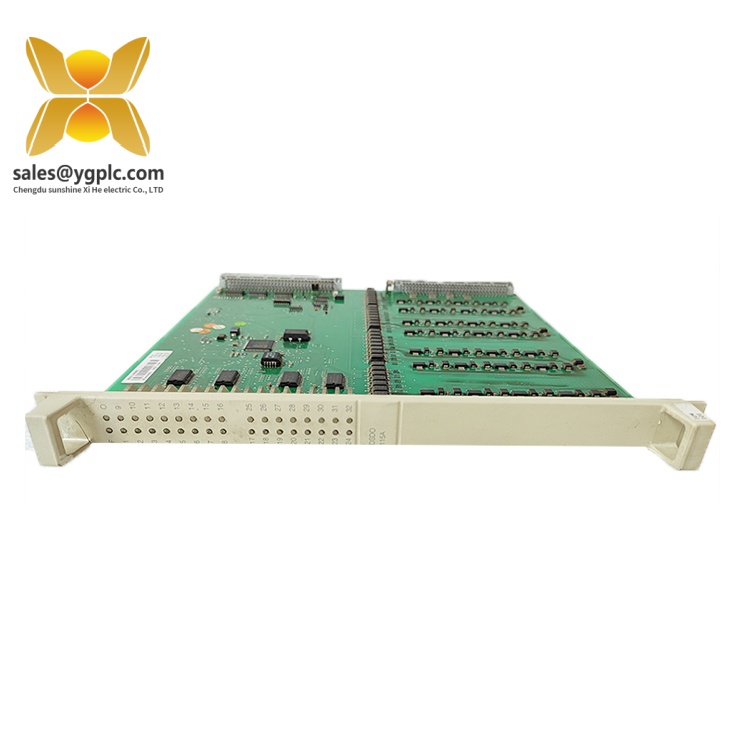

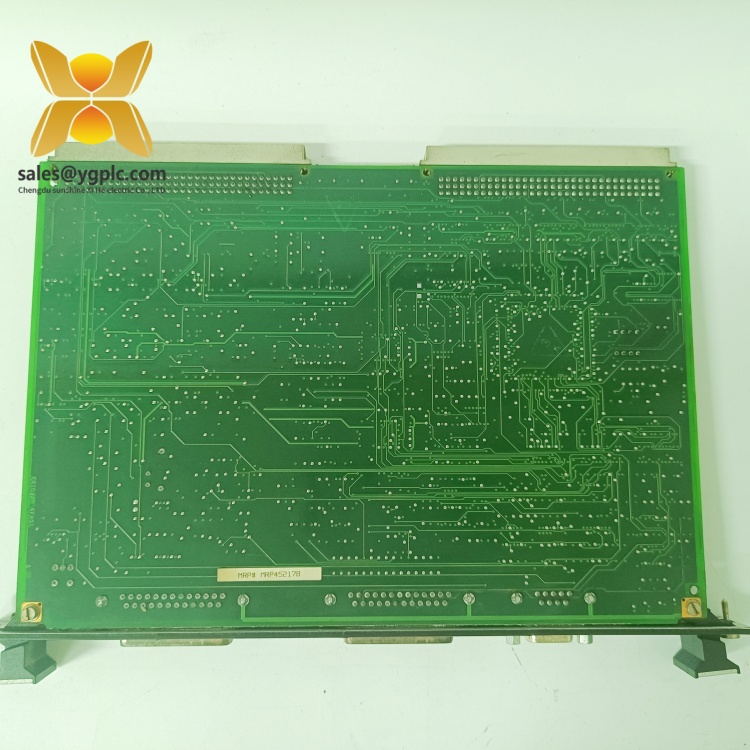

GE IS200ERIOH1AAA I/O Module for Mark VIe System

Product Overview: GE IS200ERIOH1AAA

The GE IS200ERIOH1AAA I/O module is a high-reliability industrial input/output component designed for GE’s Mark VIe distributed control system (DCS), specifically engineered for steam and gas turbine control applications. As a critical component of the Mark VIe platform, this module enables seamless communication between field devices and the control system, supporting real-time data acquisition and command execution in mission-critical power generation and process control environments. The IS200ERIOH1AAA integrates advanced signal conditioning and diagnostics, ensuring precise control and monitoring of turbine operations while maintaining system stability.

Featuring 16 channels of analog input/output and digital input/output capabilities, the IS200ERIOH1AAA adapts to diverse field signals, including 4–20 mA, 0–10 V DC, and contact closures. Its hot-swappable design allows replacement without system shutdown, minimizing downtime in power plants and industrial facilities. The module’s -40°C to +70°C operating temperature range and IP20 protection rating make it suitable for harsh environments, while its compatibility with GE’s Proficy software enables seamless integration with supervisory control and data acquisition (SCADA) systems.

Within automation architectures, the IS200ERIOH1AAA serves as a bridge between sensors/actuators and the Mark VIe controller, ensuring reliable data transmission for turbine speed regulation, valve control, and safety interlocks. Its built-in self-diagnostic functions and redundancy support enhance system availability, making it an essential component for industries requiring uninterrupted operation, such as power generation, oil & gas, and heavy manufacturing.

Technical Specifications: GE IS200ERIOH1AAA

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200ERIOH1AAA |

| Manufacturer | GE |

| Product Type | I/O Module (Analog/Digital) |

| Channel Configuration | 16 channels (mix of AI, AO, DI, DO) |

| Input Voltage Range | 4–20 mA, 0–10 V DC (analog); 24V DC (digital) |

| Output Voltage/Current | 4–20 mA, 0–10 V DC (analog); 24V DC/1A (digital) |

| Communication Protocol | Serial (RS485), parallel with Mark VIe backplane |

| Physical Dimensions | 228.6 mm (H) × 101.6 mm (W) × 76.2 mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | Rack-mounted (Mark VIe chassis) |

| Country of Origin | United States |

Main Features and Advantages: GE IS200ERIOH1AAA

Diverse I/O Capability: The IS200ERIOH1AAA supports a mix of analog and digital signals, eliminating the need for multiple modules and simplifying system architecture. This versatility makes it ideal for complex turbine control systems requiring simultaneous monitoring of temperature, pressure, and valve positions.

Rugged Industrial Design: Built to withstand harsh conditions, the module’s metal enclosure and wide temperature tolerance ensure reliable performance in high-vibration environments, such as turbine halls or offshore platforms. Its IP20 rating protects against dust and accidental contact, enhancing durability.

Hot-Swappable Functionality: The module can be replaced while the system is running, reducing maintenance downtime. This feature is critical for power plants where shutdowns for component replacement could lead to significant energy loss.

Advanced Diagnostics: Integrated self-test routines and LED status indicators enable quick fault identification, reducing troubleshooting time. The module’s diagnostic data can be accessed via GE’s Proficy software, supporting predictive maintenance strategies.

Redundancy Support: Compatible with Mark VIe’s redundant architecture, the IS200ERIOH1AAA ensures continuous operation even in the event of a module failure, enhancing system reliability in critical applications.

Application Areas: GE IS200ERIOH1AAA

The GE IS200ERIOH1AAA I/O module is widely applied in industries that demand precise control and monitoring of rotating equipment:

- Power Generation: Controls steam and gas turbines in thermal, combined-cycle, and renewable energy plants, managing speed, load, and safety shutdowns. The module’s reliability ensures stable power output and grid synchronization.

- Oil and Gas: Manages compressor and pump operations in refineries, pipelines, and offshore platforms, adjusting flow rates and pressures in real time to optimize process efficiency.

- Heavy Manufacturing: Integrates with large-scale machinery in steel mills and chemical plants, controlling hydraulic systems and monitoring process parameters to maintain production quality.

- Water Treatment: Regulates pumps and valves in water/wastewater plants, ensuring consistent flow and chemical dosing while complying with environmental standards.

- Marine Engineering: Used in ship propulsion systems to monitor engine performance and adjust fuel injection, enhancing fuel efficiency and reducing emissions.

Related Products: GE IS200ERIOH1AAA

- GE IS200ESELH1AAA (Selector Module): Works with the IS200ERIOH1AAA to manage redundant signal paths in Mark VIe systems.

- GE IS200ETVOH1AAA (Terminal Block): Provides physical connectivity for field wires, complementing the IS200ERIOH1AAA in module installations.

- GE IS200EVIOH1AAA (V/O Module): A variant with enhanced voltage handling, suitable for high-voltage industrial setups.

- GE IS200ERDOH1AAA (Relay Output Module): Extends the IS200ERIOH1AAA by adding relay-based switching for safety interlocks.

- GE IS200ERIIH1AAA (Input Module): A dedicated analog input module for systems requiring higher input channel density.

- GE IS200ERETH1AAA (Ethernet Module): Enables network connectivity for the IS200ERIOH1AAA, supporting remote monitoring via Modbus TCP/IP.

Installation and Maintenance: GE IS200ERIOH1AAA

Pre-installation Preparations:

Before installing the IS200ERIOH1AAA, verify the Mark VIe chassis is powered off and properly grounded. Clean the rack slot and ensure the module aligns with the backplane connectors. Secure the module using the provided brackets, then connect field wires to the terminal block, following GE’s wiring diagram to avoid polarity errors. After wiring, power on the system and use Proficy software to configure channel parameters (e.g., signal type, scaling).

Before installing the IS200ERIOH1AAA, verify the Mark VIe chassis is powered off and properly grounded. Clean the rack slot and ensure the module aligns with the backplane connectors. Secure the module using the provided brackets, then connect field wires to the terminal block, following GE’s wiring diagram to avoid polarity errors. After wiring, power on the system and use Proficy software to configure channel parameters (e.g., signal type, scaling).

Maintenance Recommendations:

- Routine Checks: Monthly visual inspections for loose connections, damaged cables, or overheating. Use the module’s LED indicators to verify operational status (green for normal, red for fault).

- Calibration: Annually calibrate analog channels using a certified signal source to ensure measurement accuracy. Reference GE’s calibration procedures for step-by-step guidance.

- Firmware Updates: Periodically update firmware via the Mark VIe controller to access new features and bug fixes, ensuring compatibility with evolving system requirements.

- Spare Parts Management: Keep a spare IS200ERIOH1AAA on hand, leveraging our global supply chain for quick replacement of discontinued or urgent components.

Product Guarantee: GE IS200ERIOH1AAA

Our company provides a 12-month quality warranty for the GE IS200ERIOH1AAA I/O module, covering hardware defects from non-human causes. During the warranty period, we will replace any module with abnormal signal output, communication failures, or physical damage at no cost. For urgent needs or discontinued models, our extensive inventory and global logistics network ensure prompt fulfillment, minimizing downtime and supporting continuous industrial operation.

With 17 years of expertise in industrial control distribution, we are committed to reliable products and exceptional service. The IS200ERIOH1AAA exemplifies our dedication to quality, offering robust I/O capabilities for critical turbine control systems. Contact us today to optimize your automation setup with this advanced module.

Note: All product names, logos, and brands are property of their owners. This document is informational and does not substitute for GE’s official technical manuals.

Whatsapp:+86 18859254943

E-mail :sales@ygplc.com

E-mail :sales@ygplc.com

GE IC660BBD101 CPU module

GE IC660BBD110 Pulse input (PI) module

GE IC660TBA026 Digital input module

GE IC660TBD024 Digital 24VDC output module

GE IC660BBD101 Logic controller

GE IC660BBD110 Control panel

GE IC660EBD020 Double output

GE IC660EBD025 Expansion module

GE IC660ELB912 RXM rack

GE IC660ELB912G Thermoelectric couple

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: