Description

GE IC697CHS790 90-70 Series Chassis

Product Overview

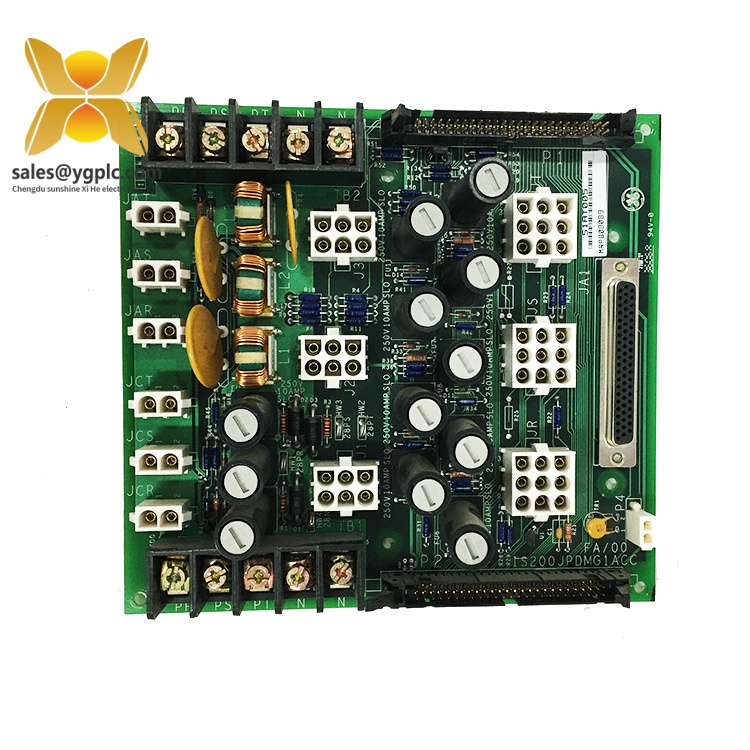

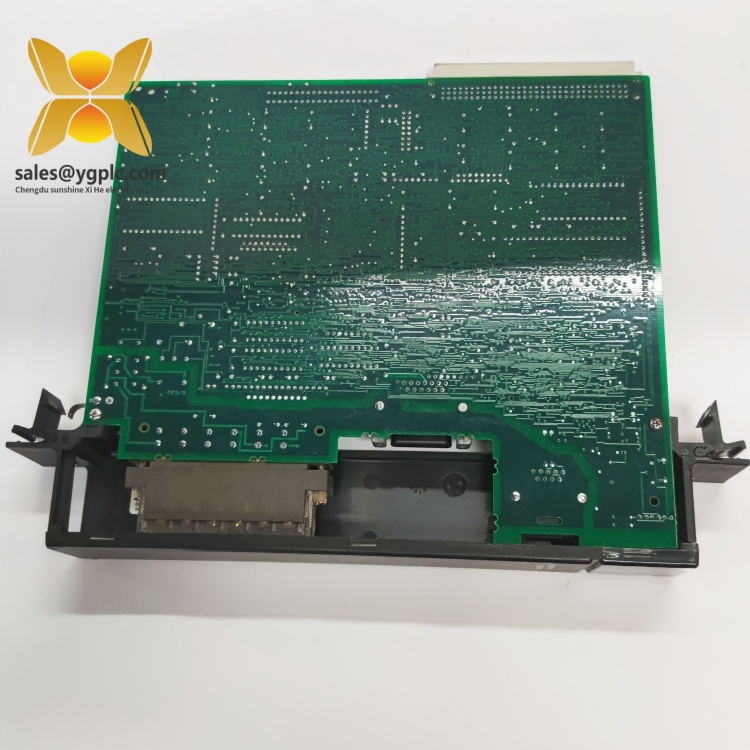

The GE IC697CHS790 is a high-reliability 90-70 Series Chassis designed to house and integrate PLC modules in industrial automation systems, serving as the physical and electrical framework for GE’s 90-70 PLC platform. Engineered to support seamless integration of CPU, I/O, and communication modules, this chassis enables the construction of robust control systems for mission-critical applications in power generation, oil & gas, and manufacturing. As part of the IC697 Series, the IC697CHS790 ensures optimal performance and reliability by providing a structured environment for module installation, power distribution, and data communication.

Featuring a rugged industrial design, the GE IC697CHS790 accommodates up to 14 modules in a standard 19-inch rack, with a modular layout that supports hot-swappable module replacement without system shutdown. Its reinforced metal enclosure and advanced cooling system maintain optimal operating temperatures for mounted modules, even in harsh environments with temperatures ranging from -40°C to +70°C. The chassis integrates redundant power supply slots, enabling dual 24 V DC inputs to enhance system resilience, while built-in backplane circuitry ensures low-latency data transfer between modules.

In automation ecosystems, the IC697CHS790 acts as the backbone of 90-70 Series PLC systems, facilitating communication between the CPU, I/O devices, and external networks. Its compatibility with GE’s Proficy Machine Edition software allows intuitive configuration and monitoring, while compliance with industry standards (e.g., IEC 61131-2) ensures reliability in demanding industrial settings. By providing a stable and scalable platform for module integration, this chassis supports the construction of complex control systems that require high availability and ease of maintenance.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697CHS790 |

| Manufacturer | GE |

| Product Type | PLC Chassis |

| Platform | 90-70 Series |

| Module Slots | 14 slots (including CPU, I/O, communication) |

| Power Supply | Dual 24 V DC inputs (19.2–28.8 V DC), redundant configuration |

| Backplane Data Rate | 10 Mbps |

| Physical Dimensions | 482.6 mm (H) × 444.5 mm (W) × 228.6 mm (D) |

| Weight | 12.7 kg |

| Operating Temperature | -40°C to +70°C |

| Mounting | 19-inch rack-mounted (standard industrial rack) |

| Certifications | CE, UL, cUL, IEC 61131-2 |

| Environmental Resistance | Vibration (IEC 60068-2-6: 5 g), shock (IEC 60068-2-27: 30 g), humidity (5–95% non-condensing) |

Key Features and Advantages

Modular Scalability: The IC697CHS790 supports up to 14 modules, allowing flexible configuration for small to large-scale control systems. This scalability enables incremental system expansion as process requirements evolve, reducing upfront investment costs.

Redundant Power Architecture: Dual power supply slots support redundant 24 V DC inputs, ensuring continuous operation during power fluctuations or supply failures. This feature is critical for mission-critical applications where downtime is not acceptable.

Hot-Swap Capability: Modules can be installed or replaced while the chassis remains powered, minimizing system downtime during maintenance or upgrades. This feature enhances operational efficiency in 24/7 industrial environments.

Robust Environmental Performance: The chassis’ metal enclosure and conformal-coated backplane withstand extreme temperatures, vibration, and electromagnetic interference, making it suitable for harsh industrial settings such as offshore platforms, refineries, and mining sites.

High-Speed Data Communication: The 10 Mbps backplane ensures low-latency data transfer between modules, enabling real-time control and monitoring of complex processes. This speed is essential for applications requiring rapid response to changing conditions.

Easy Integration and Maintenance: The chassis’ standardized design and compatibility with GE’s programming tools simplify system integration and maintenance. LED indicators for power, communication, and module status facilitate quick fault detection and troubleshooting.

Application Areas

The GE IC697CHS790 is essential for constructing reliable PLC systems across diverse industries:

- Power Generation: Houses PLC modules for controlling steam turbines, generators, and auxiliary systems in thermal, hydro, and renewable energy plants, ensuring stable power output and grid synchronization.

- Oil & Gas: Supports control systems for pipeline compression stations, refinery processes, and offshore platforms, integrating with safety instrumented systems (SIS) for emergency shutdowns and regulatory compliance.

- Manufacturing: Forms the backbone of PLC systems in automotive, pharmaceutical, and food & beverage production lines, coordinating robotic arms, conveyor systems, and quality control sensors.

- Water/Wastewater Treatment: Hosts modules for optimizing pump operations, filtration systems, and chemical dosing in water treatment plants, adapting to fluctuating demand while maintaining regulatory standards.

- Mining and Metals: Enables control of crushers, mills, and material handling systems in mining operations, ensuring efficient extraction and processing while prioritizing equipment safety.

Specific applications include:

- Complex Process Control: Integrates CPU, analog/digital I/O, and communication modules to manage multi-variable processes in chemical plants, ensuring precise control of temperature, pressure, and flow rates.

- Machine Automation: Houses modules for coordinating multi-axis robotic systems in automotive assembly lines, enabling precise motion control and error-free production.

- Building Automation: Manages heating, ventilation, and air conditioning (HVAC) systems in large facilities, optimizing energy usage and environmental conditions.

Related Products

- IC697CPU780 90-70 Series CPU Module: High-performance processor module compatible with the IC697CHS790, offering 32-bit processing for complex control logic.

- IC697PWR750 Power Supply Module: Redundant 24 V DC power supply for the IC697CHS790, ensuring uninterrupted operation during power fluctuations.

- IC697ALG392 Analog Input Module: Expands the chassis’ capabilities with high-precision analog data acquisition for process variables.

- IC697DIG360 Digital Output Module: Provides discrete output channels for driving solenoids and relays, compatible with the IC697CHS790’s backplane.

- IC697ETM710 Ethernet Module: Enables high-speed Ethernet connectivity for the chassis, supporting protocols like Modbus TCP and EtherNet/IP.

- IC697CBL701 Chassis Backplane Cable: Connects multiple IC697CHS790 chassis units for distributed control systems, expanding I/O capacity.

- IC697ACC700 Communication Module: Facilitates integration with legacy systems via serial protocols, enhancing the chassis’ interoperability.

Installation and Maintenance

Pre-installation Preparations:

Before installing modules into the GE IC697CHS790, ensure the 19-inch rack is properly grounded and ventilated. Verify the rack’s structural integrity to support the chassis’ weight (12.7 kg). Install redundant power supply modules (e.g., IC697PWR750) and connect to a stable 24 V DC power source. Use anti-static precautions when handling modules, and align them with the chassis slots to ensure secure engagement with the backplane. Configure the chassis in GE’s Proficy Machine Edition software, assigning module addresses and enabling diagnostic features.

Before installing modules into the GE IC697CHS790, ensure the 19-inch rack is properly grounded and ventilated. Verify the rack’s structural integrity to support the chassis’ weight (12.7 kg). Install redundant power supply modules (e.g., IC697PWR750) and connect to a stable 24 V DC power source. Use anti-static precautions when handling modules, and align them with the chassis slots to ensure secure engagement with the backplane. Configure the chassis in GE’s Proficy Machine Edition software, assigning module addresses and enabling diagnostic features.

Maintenance Suggestions:

- Routine Inspections: Monthly, check LED indicators on the chassis and modules for abnormal status (e.g., fault lights). Verify secure connections and clean air vents to prevent dust accumulation, which could affect thermal performance.

- Redundancy Testing: Annually test redundant power supplies by simulating a failure, ensuring seamless failover. Document test results to maintain compliance and system reliability.

- Environmental Management: Quarterly, inspect the chassis for signs of physical damage or corrosion, especially in harsh environments. Ensure the control room maintains optimal temperature (20–25°C) and humidity (40–60%) to prevent component degradation.

- Spare Parts Management: Store spare IC697CHS790 chassis units in a controlled environment to facilitate rapid replacement in case of structural damage or backplane failure.

Product Guarantee

Our company provides a 12-month quality warranty for the GE IC697CHS790, covering hardware defects under normal operating conditions. In the event of unexpected failures, such as power supply slot malfunctions or backplane issues, we offer prompt replacement services to minimize downtime. For legacy or discontinued models like the IC697CHS790, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation, configuration, and maintenance, delivering tailored solutions to maintain your control system’s integrity.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE IC693DNM200-BD Servo module

GE IC693DSM302-AE Control cabinet node unit

GE IC693MDL231 governor

GE IC695CPE400-ABAB Connecting module

GE IC695CPU315-BB driver

GE IC695CPU315-CD servo

GE IC697ALG230 Eddy current sensor

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: