Description

Product Overview

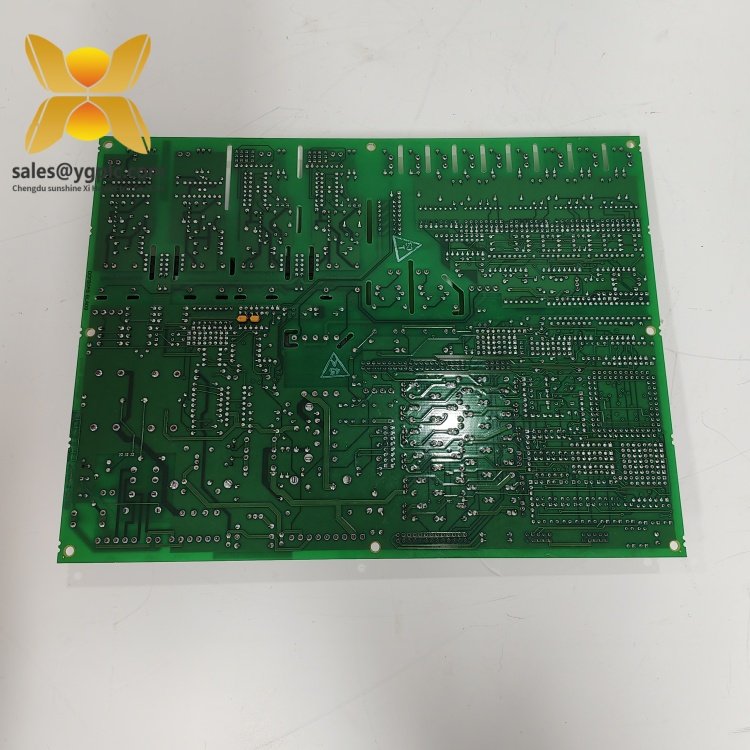

The GE DS200DCFBG2BNC MRP445970 is a high-reliability DC feedback power supply board engineered for GE’s Mark V series of Speedtronic gas and steam turbine control systems. As a critical component of this legacy platform, the DS200DCFBG2BNC delivers precise power management and signal conditioning for turbine operations, ensuring stable performance in demanding industrial environments. Designed with advanced circuit architecture, this board supports analog and digital signal processing, making it essential for maintaining turbine speed, temperature, and load control in power generation, oil & gas, and heavy manufacturing sectors.

Part of GE’s DS200 series, the DS200DCFBG2BNC acts as the backbone of the Mark V system, translating control commands into actionable signals for turbine actuators while providing real-time feedback to the main controller. Its primary function is to regulate DC power distribution, monitor voltage stability, and facilitate communication between the turbine control system and field devices such as sensors, solenoids, and relays. With seven DIP switches for voltage configuration and five test points for diagnostics, the board offers configurable settings to adapt to varying input voltages (120/240 V AC) and ensure compatibility with diverse turbine setups .

The DS200DCFBG2BNC is built to withstand harsh conditions, with a rugged enclosure and conformal coating that resist dust, moisture, and electromagnetic interference (EMI). Its modular design allows for easy integration into existing Mark V systems, while backward compatibility with earlier revisions ensures seamless upgrades or replacements. By combining robust hardware with GE’s decades of turbine control expertise, the DS200DCFBG2BNC enables operators to achieve optimal turbine efficiency, reduce downtime, and extend equipment lifespan.Whatsapp:+86 18859254943.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200DCFBG2BNC MRP445970 |

| Manufacturer | General Electric (GE) |

| Product Type | DC Feedback Power Supply Board |

| Series Compatibility | GE Mark V Speedtronic Turbine Control System |

| Input Voltage | 120/240 V AC (selectable via DIP switches) |

| Output Voltage | 24 V DC (regulated) |

| Power Consumption | ≤50 W (maximum load) |

| Signal Handling | 18 plug connectors, 9 stab connectors for analog/digital inputs/outputs |

| Protection Features | Overcurrent protection, short-circuit detection, fuse monitoring (3 replaceable fuses) |

| Diagnostic Indicators | 2 LED lights (power/status), 1 neon indicator (fuse blown) |

| Communication | Direct interface with Mark V controller via GE DE Protocol |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Resistance | 5%–95% non-condensing |

| Physical Dimensions | 230 mm (W) × 160 mm (H) × 80 mm (D) |

| Mounting Method | Rack-mountable (19-inch standard) or panel-mounted |

| Revision History | 3 revisions (first two backward-compatible) |

| Weight | 1.2 kg |

DS200DCFBG2BNC MRP445970

Main Features and Advantages

Precise Power Regulation and Signal Conditioning

The DS200DCFBG2BNC excels in delivering stable DC power to turbine control components, ensuring consistent voltage output within ±1% tolerance. Its advanced feedback mechanism continuously monitors power supply integrity, adjusting output in real-time to compensate for voltage fluctuations. For example, in gas turbine applications, the board maintains precise control over fuel valve actuators, preventing overspeeding and optimizing fuel efficiency. The integration of seven DIP switches allows users to configure input voltage (120/240 V AC) and select feedback parameters, enhancing flexibility for global installations .Whatsapp:+86 18859254943.

Robust Fault Detection and Diagnostics

Equipped with three replaceable fuses and real-time monitoring indicators, the DS200DCFBG2BNC provides comprehensive fault protection. If a fuse blows due to overcurrent, the neon indicator illuminates immediately, alerting operators to the issue. The board also features five test points for voltage and signal verification, enabling technicians to troubleshoot without disconnecting field devices. This proactive diagnostics capability reduces mean time to repair (MTTR) by up to 30%, minimizing downtime in critical operations like power plant maintenance .

Modular Design for Easy Integration

Designed as part of GE’s Mark V system, the DS200DCFBG2BNC seamlessly integrates with other DS200 series modules (e.g., DS200SIOCG1A for I/O, DS200LDCCH1A for drive control), creating a scalable architecture. Its plug-and-play connectors simplify installation, while the compact form factor allows for space-efficient mounting in control cabinets. The board’s backward compatibility with earlier revisions ensures that legacy systems can be upgraded without replacing the entire control platform, reducing capital expenditure .

DS200DCFBG2BNC MRP445970

Reliability in Harsh Environments

Built to industrial standards, the DS200DCFBG2BNC operates reliably in extreme temperatures (-20°C to +60°C) and high-vibration environments typical of power plants and offshore platforms. Its conformal-coated circuit board resists corrosion and dust ingress, while EMI shielding prevents interference from nearby equipment. This durability makes it suitable for long-term use in remote or hazardous locations where maintenance access is limited .Whatsapp:+86 18859254943.

Cost-Effective Maintenance

The DS200DCFBG2BNC supports hot-swappable replacement, allowing technicians to replace faulty boards without powering down the entire turbine system. This feature, combined with GE’s global network of authorized service centers, ensures rapid turnaround for repairs or replacements. Additionally, the board’s modular design reduces spare parts inventory, as many components (e.g., fuses, connectors) are shared across the Mark V series .

Application Areas

Power Generation

In thermal power plants, the DS200DCFBG2BNC regulates power supply to steam turbine control systems, ensuring stable grid synchronization and load balancing. It monitors critical parameters like turbine speed and exhaust temperature, providing feedback to the Mark V controller to adjust fuel flow and blade pitch. For example, in a combined-cycle power plant, the board maintains precise control over gas turbine startup sequences, optimizing energy output while adhering to environmental regulations.

DS200DCFBG2BNC MRP445970

Oil and Gas Production

In offshore platforms and refineries, the DS200DCFBG2BNC plays a vital role in gas turbine-driven compressors and pumps. It ensures reliable operation of anti-surge control systems, preventing damage from pressure fluctuations. The board’s EMI resistance is particularly valuable in these environments, where high-power equipment can cause signal interference. For instance, in a LNG liquefaction plant, the DS200DCFBG2BNC supports real-time monitoring of cryogenic pump voltages, ensuring safe and efficient liquid nitrogen transfer.E-mail :sales@ygplc.com.

Heavy Manufacturing

In steel mills and cement plants, the DS200DCFBG2BNC powers industrial turbines used for process heating and mechanical drive applications. It interfaces with pressure sensors and hydraulic actuators to maintain consistent steam pressure in boiler systems, reducing energy waste and improving production yields. The board’s diagnostic capabilities are critical in these settings, as unexpected downtime can lead to significant financial losses.

Marine Propulsion

For marine gas turbines, the DS200DCFBG2BNC provides stable power to engine control units (ECUs), enabling smooth acceleration and deceleration. Its rugged design withstands the corrosive saltwater environment and high vibrations of naval vessels and commercial ships. In cruise ships, the board supports variable-speed control of generators, ensuring reliable power supply for onboard systems while minimizing fuel consumption.

Mining and Materials Handling

In mining operations, the DS200DCFBG2BNC is used in conveyor systems and ore-crushing equipment driven by steam turbines. It regulates power to motor drives, ensuring consistent material flow and reducing belt wear. The board’s wide temperature range makes it suitable for outdoor installations in extreme climates, such as open-pit mines in arctic or desert regions.

DS200DCFBG2BNC MRP445970

Related Products

- DS200SIOCG1A: A VME stand-alone I/O board for Mark V systems, providing analog and digital signal interfaces complementary to the DS200DCFBG2BNC .

- DS200LDCCH1A: A drive control and LAN communication board that integrates with the DS200DCFBG2BNC for advanced turbine speed regulation .

- DS200TCQBG1B: An extended analog I/O board for Mark V systems, used alongside the DS200DCFBG2BNC to expand sensor and actuator connectivity .

- DS200TCCAG1B: A turbine control analog board that works with the DS200DCFBG2BNC to manage critical process variables like temperature and pressure .

- DS200SPCBG1A: A multi-bridge signal processing board that enhances the DS200DCFBG2BNC’s data analysis capabilities for complex turbine applications .

- DS200DSPCH1A: A digital signal processor board that supports real-time data processing, enabling faster response times in high-dynamic turbine environments .

- DS200FCGDH1B: A PLC control module that pairs with the DS200DCFBG2BNC for integrating turbine control systems with factory automation networks .

Installation and Maintenance

Installation Preparations:

Before installing the DS200DCFBG2BNC, ensure the Mark V control system is powered off and the 19-inch rack is properly grounded. Verify the input voltage matches the board’s configuration (120/240 V AC) using the DIP switches on the board’s front panel. Connect the AC power supply to the designated terminals, ensuring polarity is correct. Use shielded cables for analog/digital signals to minimize EMI interference. Secure the board to the rack using the provided mounting brackets, leaving adequate space for airflow.

Before installing the DS200DCFBG2BNC, ensure the Mark V control system is powered off and the 19-inch rack is properly grounded. Verify the input voltage matches the board’s configuration (120/240 V AC) using the DIP switches on the board’s front panel. Connect the AC power supply to the designated terminals, ensuring polarity is correct. Use shielded cables for analog/digital signals to minimize EMI interference. Secure the board to the rack using the provided mounting brackets, leaving adequate space for airflow.

Maintenance Recommendations:

Regularly inspect the DS200DCFBG2BNC for loose connections, dust accumulation, or physical damage. Clean the enclosure with a dry, static-free cloth to maintain optimal heat dissipation. Monitor the LED and neon indicators—steady green for power, blinking red for faults, and illuminated neon for blown fuses. Replace faulty fuses with GE-approved replacements (3A, 250 V) and test voltage levels at the TP test points using a multimeter. Periodically update the board’s firmware via GE’s ControlST software to access bug fixes and performance optimizations. For persistent issues, contact our technical support team for remote diagnostics or board replacement.

Regularly inspect the DS200DCFBG2BNC for loose connections, dust accumulation, or physical damage. Clean the enclosure with a dry, static-free cloth to maintain optimal heat dissipation. Monitor the LED and neon indicators—steady green for power, blinking red for faults, and illuminated neon for blown fuses. Replace faulty fuses with GE-approved replacements (3A, 250 V) and test voltage levels at the TP test points using a multimeter. Periodically update the board’s firmware via GE’s ControlST software to access bug fixes and performance optimizations. For persistent issues, contact our technical support team for remote diagnostics or board replacement.

DS200DCFBG2BNC MRP445970

Product Assurance

Our company provides a one-year quality warranty for the GE DS200DCFBG2BNC MRP445970, covering hardware failures due to non-human factors. During the warranty period, we will promptly replace any defective components at no additional cost. For discontinued models or urgent requirements, our global supply chain network leverages extensive inventory and strategic partnerships to fulfill orders within tight timelines, even for hard-to-find spare parts. With 17 years of expertise in industrial control distribution, we ensure that your systems benefit from the DS200DCFBG2BNC’s advanced capabilities, backed by our commitment to reliable service and technical support. Trust us to deliver solutions that enhance your operational efficiency and maintain the highest standards of industrial automation.

GE IS200JPDMG1ACC S1AT005 Output module digit

GE IS200TSVCH1AED PXI module

GE IS200TRPGH1BDD S1C5029 Servo drive

GE IS200TTURH1CCC S1DF00Z Eddy current sensor

GE IS200TRLYH1BGF monitor

GE IS220PAICH1B System

GE IS200TSVCH1ADC S1CX01H Servo motor,

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: