Description

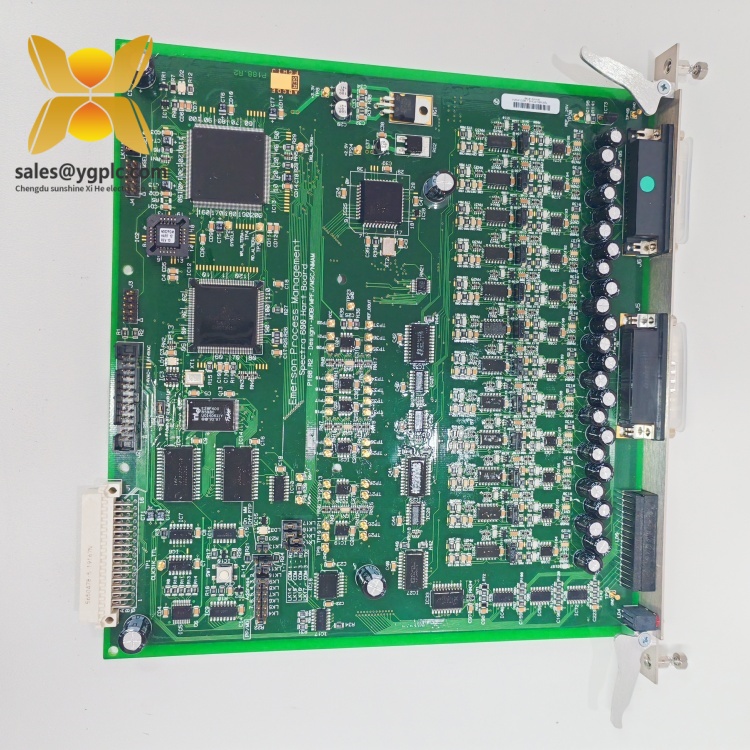

EMERSON P188.R2 Pressure Transmitter

Product Overview:EMERSON P188.R2

The EMERSON P188.R2 is a high-precision Pressure Transmitter designed for industrial process control applications, offering reliable measurement of gauge, absolute, or differential pressure in demanding environments. As part of Emerson’s Rosemount 3051 Series, this transmitter combines advanced sensor technology with rugged construction to deliver accurate and stable performance across industries such as oil & gas, chemical processing, and power generation. The P188.R2 features a modular design that supports field-configurable parameters, enabling seamless integration into existing automation systems while reducing downtime and maintenance costs.

Key functionalities of the EMERSON P188.R2 include real-time pressure conversion, digital signal processing, and compatibility with multiple communication protocols (e.g., HART, FOUNDATION Fieldbus). Its silicon resonant sensor technology ensures high accuracy (±0.075% of span) and long-term stability, making it ideal for critical processes requiring precise pressure monitoring. The transmitter’s compact form factor (140 mm height × 90 mm width) and lightweight design (1.8 kg) facilitate easy installation in both new and retrofitted systems, while its corrosion-resistant 316L stainless steel wetted parts ensure durability in harsh media applications.

In automation ecosystems, the P188.R2 serves as a critical interface between process variables and control systems, converting physical pressure inputs into standardized electrical signals (4–20 mA or digital outputs). Its built-in diagnostic capabilities monitor sensor health, power supply status, and process conditions, enabling predictive maintenance and reducing unplanned outages. Whether deployed in standalone configurations or integrated with DCS/PLC platforms, this transmitter enhances operational efficiency by providing reliable data for process optimization and safety interlocking.

Technical Specifications:EMERSON P188.R2

| Parameter Name | Parameter Value |

|---|---|

| Product Model | P188.R2 |

| Manufacturer | Emerson |

| Product Type | Pressure Transmitter |

| Measurement Range | Gauge pressure: 0–3.5 kPa to 0–414 MPa |

| Output Signal | 4–20 mA DC with HART protocol (optional FOUNDATION Fieldbus) |

| Power Supply | 10–30 V DC (two-wire system) |

| Accuracy | ±0.075% of span (standard), ±0.05% of span (high-precision option) |

| Physical Dimensions | 140 mm (H) × 90 mm (W) × 70 mm (D) |

| Weight | 1.8 kg |

| Wetted Materials | 316L stainless steel, Hastelloy C-276 (optional) |

| Operating Temperature | -40°C to +104°C |

| Process Connection | 1/2″ NPT male, DIN 11851, or flange-mounted (optional) |

| Certifications | CE, ATEX, IECEx, UL, CSA |

EMERSON P188.R2

Key Features and Advantages:EMERSON P188.R2

Advanced Sensor Technology: The P188.R2 utilizes Emerson’s silicon resonant sensor, which provides superior stability and repeatability, minimizing drift over time and reducing calibration frequency. This technology ensures reliable measurements even in high-temperature, high-pressure, or corrosive environments.

Flexible Communication Options: With native support for HART 7 and optional FOUNDATION Fieldbus protocols, the transmitter enables seamless integration with modern control systems. Its digital communication capability allows remote configuration, diagnostics, and asset management, enhancing operational flexibility.

Rugged Industrial Design: Built with a weatherproof enclosure (IP67 rating) and corrosion-resistant materials, the P188.R2 withstands harsh conditions, including vibration, shock, and exposure to chemicals. Its modular design allows easy replacement of components without recalibrating the entire system, reducing maintenance complexity.

Enhanced Diagnostics: The transmitter’s built-in self-diagnostics monitor sensor performance, signal integrity, and power supply, providing early warnings of potential failures. This proactive approach to maintenance helps prevent process disruptions and ensures compliance with industry safety standards.

Easy Installation and Configuration: The P188.R2 features a user-friendly interface and field-configurable parameters, allowing technicians to adjust measurement ranges, units, and output signals without specialized tools. Its compact size and multiple mounting options (wall, pipe, or panel) simplify installation in tight spaces.

EMERSON P188.R2

Application Areas:EMERSON P188.R2

The EMERSON P188.R2 is widely used in industries requiring precise and reliable pressure measurement:

- Oil & Gas: Monitoring wellhead pressure, pipeline flow, and storage tank levels in upstream, midstream, and downstream operations. The transmitter’s explosion-proof certification (ATEX/IECEx) makes it suitable for hazardous areas.

- Chemical and Petrochemical: Measuring pressure in reactors, distillation columns, and heat exchangers, where accuracy and corrosion resistance are critical. The optional Hastelloy C-276 wetted parts ensure compatibility with aggressive media.

- Power Generation: Optimizing boiler operations, steam turbine control, and condenser vacuum monitoring in thermal and combined-cycle power plants. The transmitter’s high-temperature tolerance supports direct installation in harsh boiler environments.

- Water/Wastewater: Monitoring pump discharge pressure, filter differential pressure, and tank levels in water treatment facilities. Its hygienic design (optional) meets standards for food and beverage applications.

Specific applications include:

- Level Measurement: Converting hydrostatic pressure into 液位 (liquid level) data for open or closed tanks, eliminating the need for separate level sensors.

- Flow Measurement: Pairing with orifice plates or flow nozzles to calculate flow rates via differential pressure measurements.

- Process Control: Providing real-time pressure data to PID controllers for automated regulation of valves, pumps, and compressors.

Related Products:EMERSON P188.R2

- P188.R1: A lower-range variant of the P188.R2, optimized for low-pressure applications (0–10 kPa) with the same sensor technology and communication capabilities.

- P188.R3: A high-pressure model supporting ranges up to 690 MPa, suitable for deep-well oil & gas applications and industrial hydraulic systems.

- P188.RA: An absolute pressure version of the transmitter, designed for measuring pressure relative to a perfect vacuum, ideal for vacuum distillation and semiconductor manufacturing.

- P188.D2: A differential pressure transmitter in the same series, used for measuring pressure differences across filters, heat exchangers, or flow elements.

- Rosemount 3051S Series: A next-generation platform offering enhanced digital capabilities, including wireless connectivity and advanced predictive diagnostics, as an upgrade path for the P188.R2.

- Rosemount 2051 Pressure Transmitter: A cost-effective alternative for basic pressure monitoring in non-critical applications, sharing the same mechanical interface but with reduced accuracy specifications.

- EMERSON PX300 Pressure Transmitter: A compact, general-purpose model for light industrial use, suitable for applications where the ruggedness of the P188.R2 is not required.

- Rosemount X-well Environmental Enclosure: A complementary product designed to protect the P188.R2 in extreme weather conditions, providing additional thermal insulation and physical protection.

EMERSON P188.R2

Installation and Maintenance:EMERSON P188.R2

Installation Preparation:

Before installing the EMERSON P188.R2, verify the process conditions (pressure range, temperature, and media compatibility) to ensure the transmitter is correctly configured. Clean the process connection and install appropriate isolation valves to facilitate maintenance without depressurizing the system. Mount the transmitter vertically or horizontally using the provided brackets, ensuring proper alignment with the process line. Connect the power supply and communication cables, following polarity guidelines to avoid damage. Use Emerson’s AMS Device Manager software to configure settings such as measurement units, damping, and alarm thresholds.

Before installing the EMERSON P188.R2, verify the process conditions (pressure range, temperature, and media compatibility) to ensure the transmitter is correctly configured. Clean the process connection and install appropriate isolation valves to facilitate maintenance without depressurizing the system. Mount the transmitter vertically or horizontally using the provided brackets, ensuring proper alignment with the process line. Connect the power supply and communication cables, following polarity guidelines to avoid damage. Use Emerson’s AMS Device Manager software to configure settings such as measurement units, damping, and alarm thresholds.

Maintenance Recommendations:

- Routine Inspections: Periodically check the transmitter’s LED indicators for fault signals and verify that the displayed pressure reading matches expected values. Inspect the enclosure for signs of damage, corrosion, or water ingress, especially in outdoor installations.

- Calibration: Perform calibration at least annually using a certified pressure source and Emerson’s calibration tools. For critical applications, consider semi-annual calibration to maintain accuracy. Document all calibration results for compliance and traceability.

- Software Updates: Regularly update the transmitter’s firmware to access new features, security patches, and protocol enhancements. Ensure backups of existing configurations before initiating updates to prevent data loss.

- Spare Parts Management: Store spare P188.R2 transmitters in a controlled environment (temperature: 15–25°C, humidity: 30–60% RH) to ensure quick replacement in case of failure. Keep spare seals and gaskets on hand for routine maintenance tasks.

EMERSON P188.R2

Product Warranty:EMERSON P188.R2

Our company provides a 12-month quality warranty for the EMERSON P188.R2, covering defects in materials and workmanship under normal use. If the transmitter exhibits abnormal performance or functional failure within the warranty period, we will promptly replace it at no additional cost. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of hard-to-find components, minimizing downtime and supporting continuous industrial operations. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, ensuring reliable performance throughout the product’s lifecycle.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

EMERSON A6210 Digital relay output module

EMERSON A6410 Output module digit

EMERSON A6740 PXI module

EMERSON KJ2221X1-BA1 Servo drive

EMERSON SLS1508 Servo motor

ABB GJR5252300R3101 07AC91F FIM card

ABB TVOC-2-240 1SFA664001R1001 Communication input interface component

ABB 07KT92 CS31 rack

ABB AC900F PM904F 3BDH001002R0001 AI/AO/DI/DO module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: