Description

Product Overview

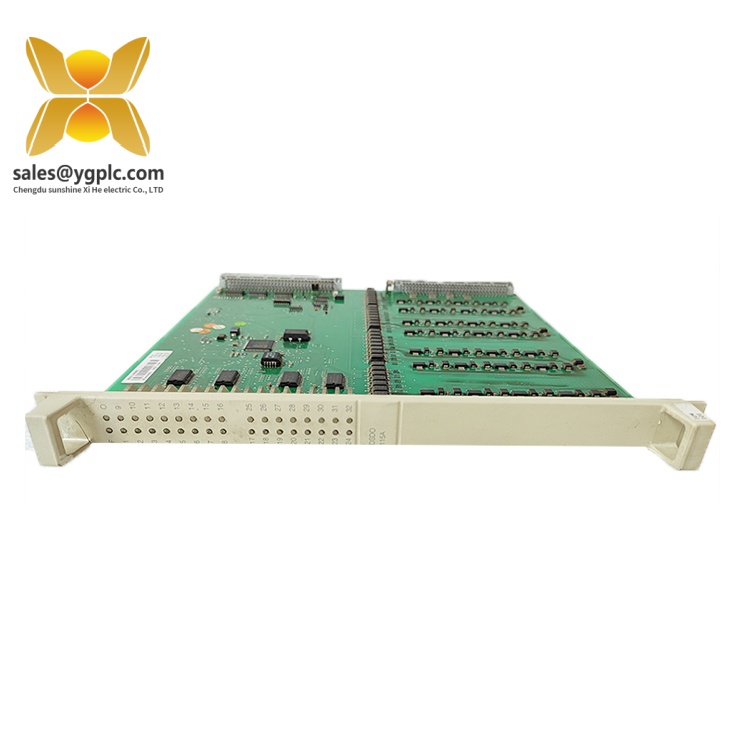

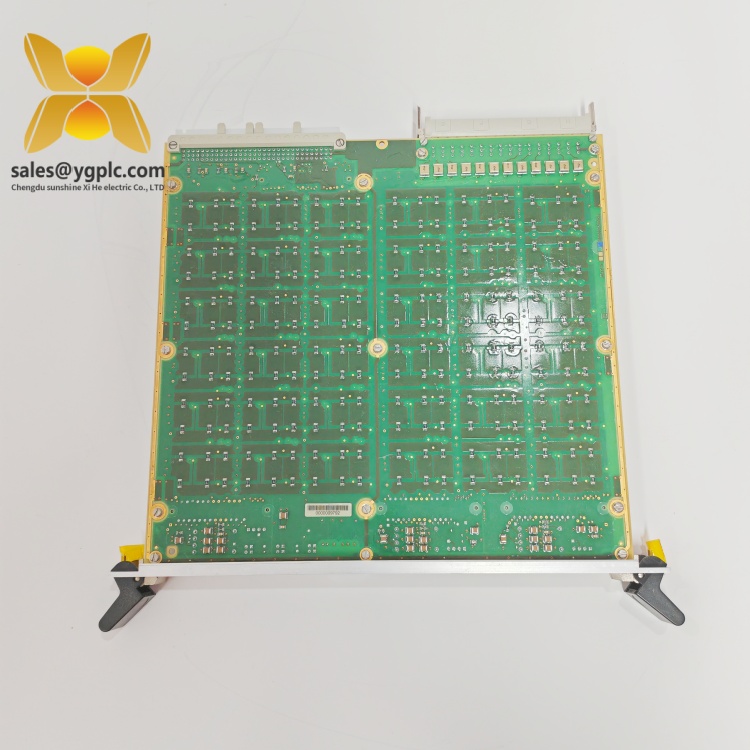

The ALSTOM DSI1817 TRVC062335000 CP00003934 is a high – reliability digital input module engineered by ALSTOM, a globally recognized leader in industrial automation and power generation solutions. As a critical component of ALSTOM’s advanced control systems, this module is designed to acquire and process digital signals from field devices, enabling precise monitoring and control in complex industrial environments. Part of ALSTOM’s modular automation platform, the DSI1817 TRVC062335000 CP00003934 is built to meet the rigorous demands of mission – critical applications, ensuring seamless integration with PLCs, DCS systems, and other control architectures.

The ALSTOM DSI1817 TRVC062335000 CP00003934 serves as a bridge between field – level devices such as switches, sensors, and relays and the higher – level control system. It features multiple isolated input channels that can detect the state of digital signals (e.g., ON/OFF, contact closure) and convert them into standardized digital data for processing. With its robust design and advanced signal conditioning, the module ensures accurate signal acquisition even in harsh environments characterized by high electromagnetic interference, vibrations, or temperature fluctuations.Whatsapp:+86 18859254943.

In industrial automation setups, the DSI1817 TRVC062335000 CP00003934 plays a pivotal role in enabling real – time monitoring of equipment status, safety interlocks, and process conditions. It supports a wide range of input voltages and signal types, making it compatible with diverse field devices. Whether used in power generation plants, manufacturing facilities, or transportation systems, this module enhances system reliability by providing stable and noise – free digital input signals, thus contributing to efficient control strategies and proactive maintenance practices.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DSI1817 TRVC062335000 CP00003934 |

| Manufacturer | ALSTOM |

| Product Type | Digital Input Module |

| Input Channels | 16 isolated channels |

| Input Signal Types | 24 V DC (TTL/CMOS compatible), dry contact (contact closure) |

| Signal Detection | Voltage level detection (active high/low), contact state monitoring |

| Isolation Level | 2.5 kV AC galvanic isolation between channels and system ground |

| Power Supply | 24 V DC ±15% (wide range for stable operation) |

| Power Consumption | ≤5 W (low power design for energy efficiency) |

| Communication Interface | Profibus DP, Modbus RTU, Ethernet/IP (optional with communication module) |

| Operating Temperature | – 40°C to + 70°C (extended range for harsh environments) |

| Storage Temperature | – 40°C to + 85°C |

| Humidity Resistance | 0%–95% non – condensing |

| Physical Dimensions | 100 mm (W) × 150 mm (H) × 80 mm (D) (compact design for space – efficient installations) |

| Mounting Method | DIN – rail mountable (EN 60715 standard) |

| Diagnostic Features | LED indicators for power, channel status, and fault detection; built – in self – test (BIST) |

| Compliance Standards | CE, UL, IEC 61131 – 2, IEC 61000 – 6 – 2 (EMC immunity), IEC 61000 – 6 – 3 (EMC emission) |

DSI1817 TRVC062335000 CP00003934

Main Features and Advantages

High – Integrity Signal Acquisition

The ALSTOM DSI1817 TRVC062335000 CP00003934 ensures precise detection of digital signals with its 16 isolated input channels, each capable of handling both voltage – based and contact – based signals. The galvanic isolation of 2.5 kV AC protects the control system from ground loops and transient voltage spikes, a critical feature in industrial settings where electrical noise is prevalent. This isolation not only safeguards the module but also enhances the overall reliability of the control system by minimizing signal distortion and interference.

Versatile Signal Compatibility

Supporting both 24 V DC signals and dry contact inputs, the module adapts to a wide range of field devices, from proximity sensors and limit switches to safety relays and pushbuttons. This versatility eliminates the need for multiple specialized modules, simplifying inventory management and reducing integration complexity. The module’s ability to distinguish between active high/low states and contact closure/opening provides detailed status information, enabling accurate monitoring of equipment operations and process conditions.Whatsapp:+86 18859254943.

Robust Industrial Design

Engineered for durability, the DSI1817 TRVC062335000 CP00003934 operates reliably across an extreme temperature range of – 40°C to + 70°C, making it suitable for outdoor installations, offshore platforms, and industrial zones with significant thermal variations. Its rugged enclosure resists dust, moisture, and mechanical vibrations, while conformal coating on the circuit board protects against corrosive atmospheres. These features ensure consistent performance in harsh environments where equipment failure could lead to costly downtime.

Advanced Diagnostic Capabilities

Built – in diagnostic functions, including LED indicators for each channel and a self – test feature, allow for quick identification of faults such as open circuits, short circuits, or power anomalies. The module continuously monitors its operational status and communicates diagnostic information to the control system, enabling proactive maintenance and reducing troubleshooting time. This predictive capability is invaluable in mission – critical applications where system availability is paramount.

Seamless System Integration

With support for multiple communication protocols such as Profibus DP, Modbus RTU, and Ethernet/IP (via optional modules), the ALSTOM DSI1817 TRVC062335000 CP00003934 integrates effortlessly with both legacy and modern control systems. Its plug – and – play design and standardized interface simplify configuration, while the modular architecture of ALSTOM’s automation platform allows for easy expansion or replacement without disrupting ongoing operations. This flexibility makes it an ideal choice for retrofitting existing systems or building new automation setups from scratch.

DSI1817 TRVC062335000 CP00003934

Application Areas

Power Generation

In thermal, hydro, and nuclear power plants, the ALSTOM DSI1817 TRVC062335000 CP00003934 monitors the status of circuit breakers, valves, and safety interlocks. It captures digital signals from turbine control systems, generator protective relays, and switchgear, providing real – time data to the plant’s distributed control system (DCS). This enables operators to monitor equipment health, detect abnormal states, and initiate protective actions, ensuring the safe and efficient operation of power generation units.

Manufacturing and Process Industries

In manufacturing facilities, the module detects the position of robotic arm end – effectors, the status of conveyor belt sensors, and the activation of safety guards. It integrates with PLCs to control production lines, ensuring that each stage of the process (e.g., material handling, quality inspection) operates in sync. In chemical and petrochemical plants, it monitors the state of pumps, valves, and emergency shutdown (ESD) systems, contributing to the safe handling of hazardous materials and compliance with strict safety standards.

Transportation and Logistics

For railway systems, the DSI1817 TRVC062335000 CP00003934 acquires signals from train door sensors, trackside switches, and signaling devices, enabling real – time monitoring of train movements and infrastructure status. In automated warehouses, it detects the presence of goods on conveyor belts, the position of automated guided vehicles (AGVs), and the status of storage system locks, facilitating seamless integration with warehouse management systems for optimized material flow.

Oil and Gas

In upstream and downstream oil and gas facilities, the module monitors the status of wellhead valves, pipeline pressure switches, and gas detection sensors. It provides critical input to safety instrumented systems (SIS), ensuring that protective measures are activated promptly in the event of leaks, overpressure, or other abnormal conditions. Its rugged design is particularly suited for offshore platforms and refineries, where exposure to saltwater, high humidity, and extreme temperatures is common.

DSI1817 TRVC062335000 CP00003934

Related Products

- ALSTOM DSO1817 TRVC062336000 CP00003935: A complementary digital output module with 16 isolated channels, designed to work in tandem with the DSI1817 TRVC062335000 CP00003934 to form a complete input/output solution for control systems. It converts digital control signals into physical outputs to drive relays, solenoids, and other actuators.

- ALSTOM AI1815 TRVC062332000 CP00003932: An analog input module that expands the system’s data acquisition capabilities by processing voltage/current signals from sensors such as thermocouples and pressure transmitters. It pairs with the DSI1817 to create a mixed – signal control solution.Whatsapp:+86 18859254943.

- ALSTOM CM1820 TRVC062340000 CP00003938: A communication module that enhances the DSI1817’s connectivity by supporting advanced protocols like Profinet or EtherCAT, enabling high – speed data exchange with industrial Ethernet networks.

- ALSTOM PM1801 TRVC062301000 CP00003930: A power supply module optimized for ALSTOM’s modular system, providing stable 24 V DC power to the DSI1817 and other connected modules, with built – in surge protection for reliable operation.

- ALSTOM FTA1800 TRVC062305000 CP00003931: A field termination assembly that simplifies wiring between the DSI1817 and field devices, offering secure terminal connections and cable management for enhanced installation efficiency.

- ALSTOM DSI1816 TRVC062334000 CP00003933: A lower – channel variant with 8 isolated input channels, suitable for smaller – scale applications or distributed control setups where fewer inputs are required, while maintaining the same rugged design as the DSI1817.

Installation and Maintenance

Installation Preparations:

Before installing the ALSTOM DSI1817 TRVC062335000 CP00003934, ensure all power sources to the control system are disconnected to prevent electrical hazards. Verify the module’s compatibility with the target control system, including voltage requirements, communication protocols, and software drivers. Mount the module securely on a 35 mm DIN – rail in a suitable control cabinet, ensuring adequate ventilation to dissipate heat. Connect field device cables to the terminal blocks, following the wiring diagram to differentiate between input signals and power connections. Finally, configure the module’s address and communication parameters using the dedicated software tool, ensuring seamless integration with the control system network.

Before installing the ALSTOM DSI1817 TRVC062335000 CP00003934, ensure all power sources to the control system are disconnected to prevent electrical hazards. Verify the module’s compatibility with the target control system, including voltage requirements, communication protocols, and software drivers. Mount the module securely on a 35 mm DIN – rail in a suitable control cabinet, ensuring adequate ventilation to dissipate heat. Connect field device cables to the terminal blocks, following the wiring diagram to differentiate between input signals and power connections. Finally, configure the module’s address and communication parameters using the dedicated software tool, ensuring seamless integration with the control system network.

Maintenance Recommendations:

Regularly inspect the DSI1817 TRVC062335000 CP00003934 for physical damage, loose connections, or dust accumulation, which can affect signal integrity. Clean the module’s exterior with a dry, static – free cloth to maintain optimal heat dissipation. Monitor the LED indicators for any fault signals: a steady green light indicates normal operation, while a blinking red light may signal a channel error or power issue. Use the control system’s diagnostic software to periodically check for firmware updates, which can improve performance and add new features. In the event of a persistent fault, replace the module with a spare unit following the shutdown and isolation procedures outlined in the user manual. For advanced troubleshooting, contact ALSTOM’s technical support or our experienced service team, who can provide remote assistance or on – site maintenance as needed.

Regularly inspect the DSI1817 TRVC062335000 CP00003934 for physical damage, loose connections, or dust accumulation, which can affect signal integrity. Clean the module’s exterior with a dry, static – free cloth to maintain optimal heat dissipation. Monitor the LED indicators for any fault signals: a steady green light indicates normal operation, while a blinking red light may signal a channel error or power issue. Use the control system’s diagnostic software to periodically check for firmware updates, which can improve performance and add new features. In the event of a persistent fault, replace the module with a spare unit following the shutdown and isolation procedures outlined in the user manual. For advanced troubleshooting, contact ALSTOM’s technical support or our experienced service team, who can provide remote assistance or on – site maintenance as needed.

DSI1817 TRVC062335000 CP00003934

Product Assurance

Our company provides a one – year quality warranty for the ALSTOM DSI1817 TRVC062335000 CP00003934, covering all hardware failures resulting from non – human factors. During the warranty period, we will promptly replace any module that exhibits performance anomalies or functional defects, ensuring minimal disruption to your operations. For discontinued models or urgent requirements, our global supply chain network is optimized to source and deliver scarce spare parts quickly, leveraging our 17 years of expertise in industrial control distribution. We understand the critical role that reliable input modules play in maintaining system stability, and our commitment to customer satisfaction drives us to provide consistent, high – quality service. Trust us to support your industrial automation needs with the ALSTOM DSI1817 TRVC062335000 CP00003934, backed by our extensive inventory and dedicated technical support.

AMAT 0010-23716 driver

PACIFIC 33VM52-000-29 Eddy current sensor

Nabtesco BTC-304 monitor

Elmo G-TUB30-480ERSS0 rack

Woodward 8237-1369 Remote module

Woodward 8237-1600 Main processor

ALSTOM CMP1838 TRVCO62345000 CP00005202 Pulse input

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: