Description

BENTLY 3300/16-14-01-03-00-00-01 Product Specification

Product Overview

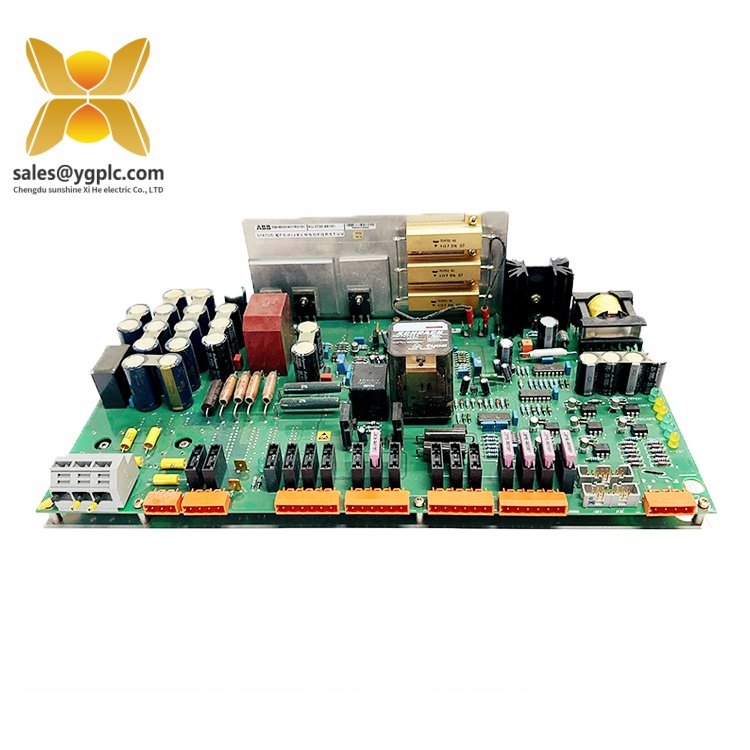

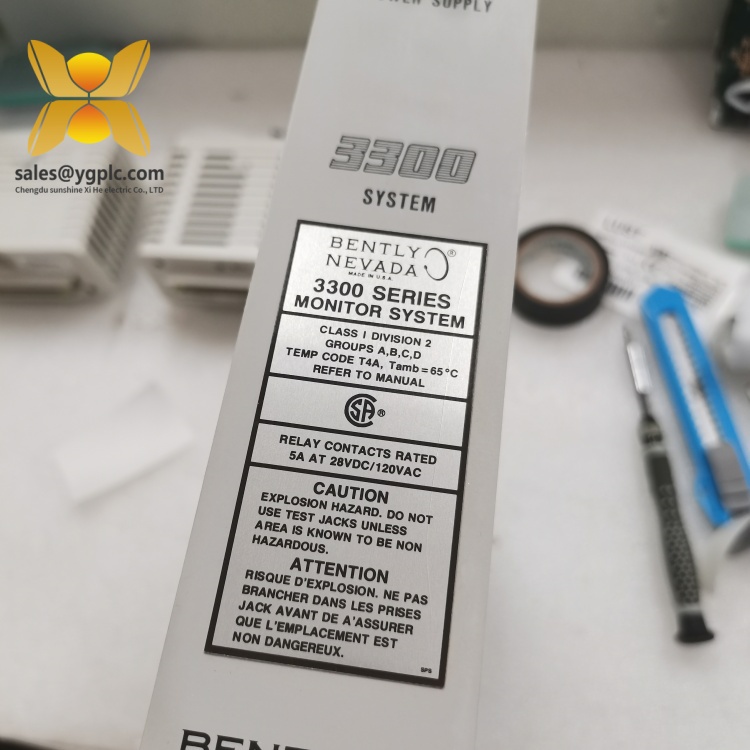

The BENTLY 3300/16-14-01-03-00-00-01 is a high-reliability 16-slot rack frame designed for BENTLY’s 3300 Series Machinery Protection System. Engineered to serve as the physical and electrical backbone of industrial monitoring systems, this rack frame provides a robust platform for integrating various 3300 Series modules, such as vibration monitors, temperature controllers, and communication gateways. The BENTLY 3300/16-14-01-03-00-00-01 features a 19″ rack-mount design with 16 module slots, enabling comprehensive machinery health monitoring in industries like oil and gas, power generation, and manufacturing.

Constructed with a rugged steel enclosure, the BENTLY 3300/16-14-01-03-00-00-01 ensures stable mechanical and electrical performance in harsh environments. It supports hot-swappable module installation, allowing maintenance without system shutdowns, and integrates dual redundant power supplies for uninterrupted operation. The frame’s backplane architecture enables high-speed data transfer between modules, ensuring real-time communication for critical machinery protection. With its standardized design, the BENTLY 3300/16-14-01-03-00-00-01 simplifies system expansion and compatibility with existing 3300 Series components.

In automation systems, the BENTLY 3300/16-14-01-03-00-00-01 acts as the central hub for machinery protection, providing a structured framework for installing and interconnecting monitoring modules. Its modular design allows engineers to configure systems based on specific application needs, from basic vibration monitoring to complex multi-channel machinery health management. By ensuring reliable mechanical support and electrical connectivity, the frame enhances the overall reliability and maintainability of industrial monitoring setups.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY 3300/16-14-01-03-00-00-01 |

| Manufacturer | BENTLY NEVADA |

| Product Type | 16-Slot Rack Frame for 3300 Series |

| Number of Slots | 16 slots (14 primary + 2 auxiliary) |

| Physical Dimensions | 482.6 mm (W) × 133.4 mm (H) × 304.8 mm (D) [19″ × 5.25″ × 12″] |

| Weight | 7.5 kg |

| Mounting | 19″ rack-mount (EIA-310 compliant) |

| Power Supply | Dual redundant 24 VDC inputs (10–30 VDC range) |

| Backplane Data Rate | 10 Mbps (parallel communication) |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5–95% non-condensing |

| Vibration Resistance | 5–500 Hz, 2 g (IEC 60068-2-6) |

| Certifications | CE, UL, CSA |

Main Features and Advantages

Modular 16-Slot Design: The BENTLY 3300/16-14-01-03-00-00-01 accommodates up to 14 primary modules and 2 auxiliary modules, enabling flexible configuration for diverse monitoring needs. This scalability allows systems to grow from basic setups to complex multi-channel configurations without replacing the frame.

Redundant Power Architecture: Dual redundant power supplies ensure continuous operation even during power fluctuations, minimizing downtime in critical applications. The frame’s power management system automatically switches to the backup supply in case of failure, enhancing system reliability.

Hot-Swap Capability: Modules can be inserted or removed while the frame is powered, allowing maintenance and upgrades without shutting down the system. This feature is invaluable in 24/7 industrial environments where downtime is costly.

Rugged Industrial Construction: The steel enclosure and reinforced backplane withstand harsh conditions, including vibration, temperature extremes, and electromagnetic interference (EMI). This durability ensures long-term reliability in oil refineries, power plants, and manufacturing facilities.

Standardized Interface: Compatible with all 3300 Series modules, the frame ensures seamless integration of vibration monitors, speed controllers, and communication gateways. This standardization simplifies inventory management and reduces training requirements for maintenance teams.

Application Areas

The BENTLY 3300/16-14-01-03-00-00-01 is essential in industries requiring robust machinery protection systems:

-

Oil and Gas:

- Installed in offshore platforms and refineries to host vibration monitoring modules for compressors and pumps, preventing catastrophic failures in critical fluid transfer systems.

- Supports emergency shutdown (ESD) systems by integrating safety-rated modules for real-time fault detection.

-

Power Generation:

- Houses turbine monitoring modules in power plants, enabling real-time analysis of shaft vibration, temperature, and speed in steam and gas turbines.

- Facilitates condition-based maintenance by hosting modules that collect data for predictive analytics, reducing unplanned outages.

-

Manufacturing:

- Manages high-speed rotating machinery in automotive and pharmaceutical plants, ensuring production continuity by monitoring motor bearings and conveyor systems.

- Integrates with SCADA systems to provide real-time health data for quality control and process optimization.

-

Water/Wastewater Treatment:

- Hosts modules for monitoring pumps and blowers in treatment facilities, maintaining consistent water flow and quality by detecting early signs of equipment degradation.

- Hosts modules for monitoring pumps and blowers in treatment facilities, maintaining consistent water flow and quality by detecting early signs of equipment degradation.

Related Products

- BENTLY 3300/10-01-01-01-00-00-01: A 10-slot rack frame for smaller setups, suitable for basic monitoring needs where fewer modules are required.

- BENTLY 3300/20-14-01-03-00-00-01: A 20-slot frame for large-scale systems, offering higher module density than the BENTLY 3300/16-14-01-03-00-00-01.

- BENTLY 3300/16-24-01-03-00-00-01: A variant with 24 VAC power input, suitable for environments where DC power is not available.

- BENTLY 3300/95 129411-01: A redundant power supply module compatible with the frame, enhancing power system reliability.

- BENTLY 3300/22M 146031-01: A vibration monitoring module that installs in the frame, providing real-time vibration analysis for rotating equipment.

Installation and Maintenance

Pre-installation Preparation:

Before installing the BENTLY 3300/16-14-01-03-00-00-01, ensure the following:

Before installing the BENTLY 3300/16-14-01-03-00-00-01, ensure the following:

- Verify the installation site meets environmental requirements (-25°C to +60°C temperature, <95% humidity) and that the 19″ rack is properly grounded.

- Prepare the power supply: connect dual 24 VDC sources to the frame’s redundant power inputs, ensuring polarity is correct to avoid damage.

- Plan module placement based on functionality (e.g., vibration monitors in central slots for optimal heat dissipation) and refer to BENTLY’s configuration guidelines for slot assignments.

Maintenance Recommendations:

- Routine Inspections: Monthly checks for loose connections, damaged cables, or overheating, using the frame’s status LEDs to identify anomalies. Clean dust from ventilation slots to maintain optimal airflow.

- Power Supply Testing: Quarterly verification of redundant power supplies using a multimeter to ensure voltage stability. Replace batteries in backup power units as recommended.

- Firmware Management: Periodically update frame and module firmware via BENTLY’s software tools to access new features and security patches, ensuring compatibility with the latest monitoring algorithms.

- Module Health Checks: Annually test module functionality using BENTLY’s diagnostic tools, replacing any faulty modules promptly to maintain system integrity.

Product Warranty

Our company provides a one-year quality warranty for the BENTLY 3300/16-14-01-03-00-00-01, covering hardware failures due to non-human factors. During the warranty period, we will replace the frame if it exhibits structural defects or electrical malfunctions. For discontinued models like the BENTLY 3300/16-14-01-03-00-00-01, our global supply chain ensures rapid fulfillment of urgent orders. We also offer post-warranty technical support, including repair services and compatibility advice, to help maintain your machinery protection system’s reliability over its lifecycle.

Contact Information:

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

Note: This document is based on technical data from BENTLY’s official specifications and industry applications. For detailed installation guides, refer to the BENTLY 3300/16-14-01-03-00-00-01 user manual or contact our technical support team.

BENTLY 3500/92 136180-01 Servo motor,

BENTLY 3500/92 136188-01 Industrial keyboard

BENTLY 3500/94 145988-01 encoder

BENTLY 3500/22M 138607-01 Expansion rack

BENTLY 3500/94 147663-01 Switch quantity input card

BENTLY 350022 288055-01 programmable

BENTLY 135489-02 Logic controller

BENTLY 3500/45 176449-04 S100

BENTLY 3500/65 145988-02 I/O

BENTLY 330876-03-50-00-00 S200

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: