Description

Product Overview

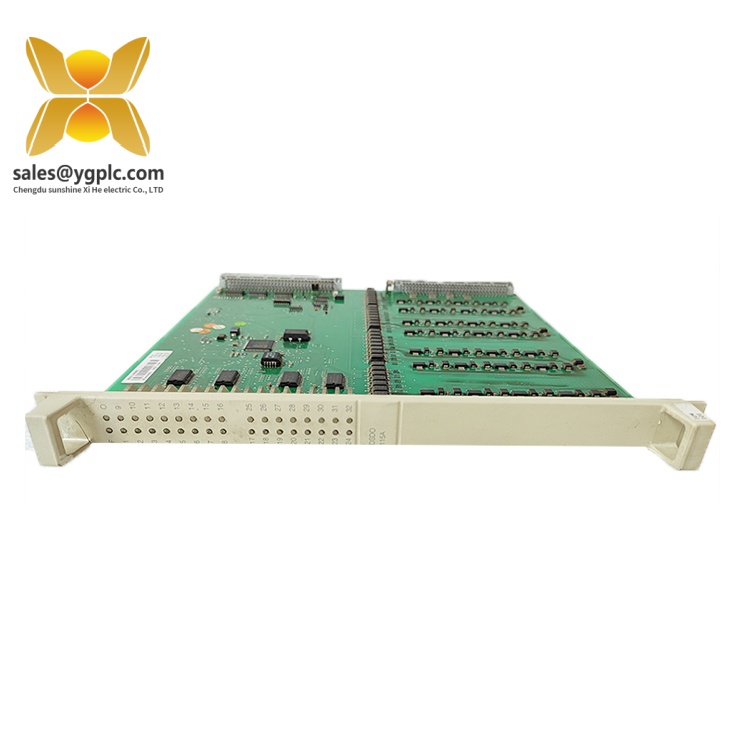

The ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 is a high-reliability input/output (I/O) bus interface module designed for critical railway signaling systems and industrial automation applications. Engineered by ALSTOM, a global leader in transportation and power solutions, this module serves as a core component of the iLOCK® computer-based interlocking system, ensuring seamless communication between control systems and field devices in safety-critical environments.

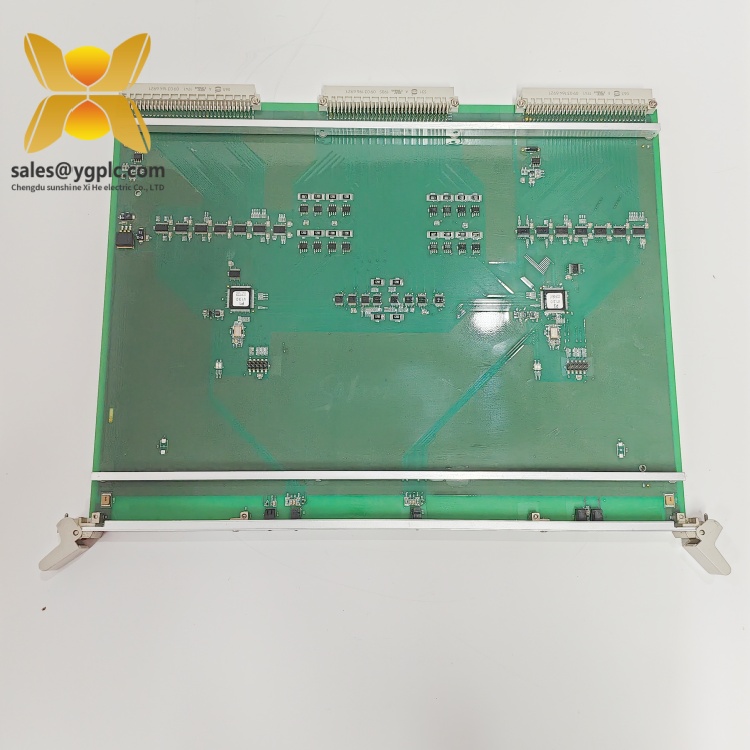

As part of ALSTOM’s advanced signaling portfolio, the I/OBUS2 12004-103-01 VER:V1.2.0 acts as a bridge between the Vehicle Logic Evaluation (VLE) board and input/output (I/O) boards, enabling real-time data exchange and synchronization of control commands . It supports dual-redundant communication paths, ensuring continuous operation even in the event of a single-channel failure. The module is specifically designed for railway interlocking systems, where precision, speed, and fail-safe operation are paramount, making it ideal for applications such as station interlocking, level crossing control, and train routing management.

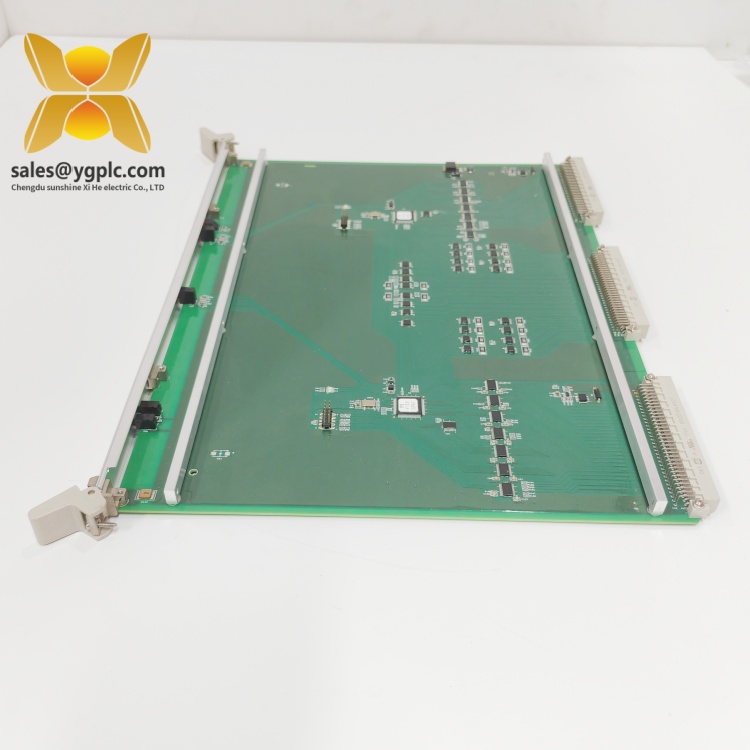

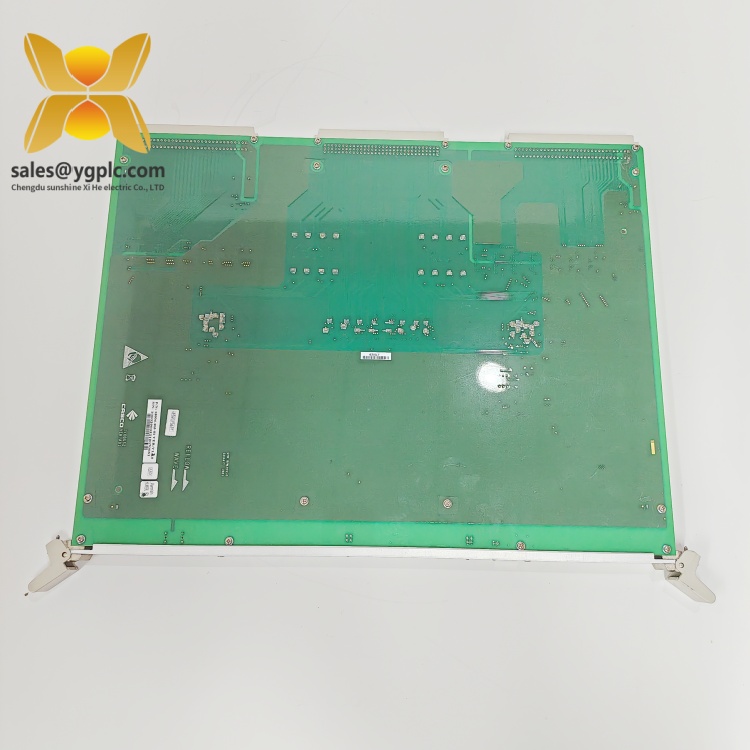

The I/OBUS2 12004-103-01 VER:V1.2.0 features a modular design that allows for flexible integration with ALSTOM’s iLOCK® system components, including the I/OBE2 (I/O Bus Extension) board for differential signal transmission. It provides secure storage for test data and port verification information, while its embedded logic and timing circuits ensure accurate control of output port validation cycles . With compliance to EN 50155 (railway electronic equipment standards) and IEC 61131-3 programming guidelines, the module guarantees reliable performance across a wide range of operating conditions, from harsh outdoor environments to high-vibration railway installations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | I/OBUS2 12004-103-01 VER:V1.2.0 |

| Manufacturer | ALSTOM |

| Product Type | Input/Output Bus Interface Module |

| System Compatibility | iLOCK® Computer-Based Interlocking System |

| Communication Protocol | Proprietary ALSTOM iLOCK® Bus Protocol (dual-redundant) |

| I/O Channels | 32 bi-directional channels (configurable for digital input/output) |

| Input Voltage | 24 V DC (±10%) |

| Power Consumption | ≤8 W (typical) |

| Signal Isolation | 500 V DC between field and system |

| Operating Temperature | -40°C to +70°C |

| Humidity Resistance | 5%–95% non-condensing |

| Physical Dimensions | 160 mm (W) × 100 mm (H) × 80 mm (D) |

| Mounting Method | DIN-rail (35 mm) or panel mount with shock-absorbing brackets |

| Protection Class | IP20 (front panel), IP54 with optional enclosure |

| Redundancy Features | Dual-redundant communication channels, self-diagnostic monitoring |

| Diagnostic Indicators | LED status for power, communication, and channel health; fault logging via iLOCK® system software |

Main Features and Advantages

High-Speed Redundant Communication

The ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 incorporates dual-redundant communication channels, ensuring uninterrupted data transfer between the VLE board and I/O modules. This redundancy minimizes downtime risks, critical for railway signaling systems where even a brief interruption could compromise safety. For example, in a metro station, the module can simultaneously transmit control commands to multiple points and signals through both channels, with automatic failover to the secondary path if a fault is detected .

Fail-Safe Design for Railway Applications

Compliant with EN 50129 (Railway Applications – Communication, Signaling, and Processing Systems), the module employs fail-safe principles to ensure that any component failure results in a safe state. Its built-in self-diagnostic capabilities continuously monitor signal integrity, power supply stability, and thermal conditions, triggering alarms or initiating protective actions when anomalies are detected. This level of safety is essential for applications like level crossing control, where system reliability directly impacts public safety.

Modular Flexibility and Scalability

The I/OBUS2 12004-103-01 VER:V1.2.0 supports seamless integration with ALSTOM’s iLOCK® system modules, including the I/OBE2 (I/O Bus Extension) board for extended signal transmission. Its 32 configurable I/O channels can be dynamically allocated to meet specific project requirements, such as monitoring track circuits, controlling point machines, or interfacing with train detection systems. This flexibility allows the module to adapt to both small-scale railway stations and large, complex interlocking systems.

Rugged Industrial Construction

Designed for harsh railway environments, the module withstands extreme temperatures (-40°C to +70°C), high vibrations (up to 5 g), and electromagnetic interference (EMI). Its compact, shock-resistant enclosure and conformal coating protect against dust, moisture, and corrosion, ensuring long-term reliability in outdoor installations or high-traffic railway yards. The DIN-rail mounting design simplifies installation and maintenance, while hot-swappable capabilities enable module replacement without disrupting system operation.

Advanced Diagnostic Capabilities

The module provides real-time diagnostic feedback via LED indicators and iLOCK® system software, offering detailed insights into channel status, communication health, and fault conditions. For instance, a flickering red LED might indicate a communication timeout with a specific I/O board, prompting maintenance teams to investigate and resolve the issue proactively. This proactive approach reduces mean time to repair (MTTR) and enhances overall system availability.

Application Areas

Railway Signaling Systems

The ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 is a cornerstone of ALSTOM’s iLOCK® interlocking system, widely used in metro networks, freight railways, and high-speed rail lines. It controls point machines, signals, and level crossings, ensuring safe and efficient train routing. For example, in a high-speed rail hub, the module coordinates the movement of multiple trains by transmitting commands to switch points and signaling systems, while monitoring track occupancy and train speed.

Industrial Automation and Power Plants

Beyond railways, the module finds applications in industrial automation systems requiring high-reliability I/O communication. It interfaces with PLCs, SCADA systems, and distributed control systems (DCS) to manage critical processes in power plants, oil refineries, and manufacturing facilities. For instance, in a power plant, the I/OBUS2 12004-103-01 VER:V1.2.0 can monitor turbine status, control generator synchronization, and manage emergency shutdown systems.

Safety-Critical Infrastructure

Given its fail-safe design, the module is ideal for safety-critical infrastructure such as nuclear power plants and defense installations. It ensures secure communication between safety systems and field devices, adhering to strict regulatory standards. In a nuclear reactor control room, the module might transmit shutdown commands to cooling systems while monitoring radiation levels, maintaining a safe operational envelope.

Mass Transit Systems

In metro and light rail systems, the I/OBUS2 12004-103-01 VER:V1.2.0 supports automatic train operation (ATO) and automatic train protection (ATP) systems. It interfaces with onboard computers, trackside equipment, and passenger information systems, enabling seamless integration of signaling and passenger services. For example, in an automated metro line, the module can synchronize platform screen doors with train arrival/departure signals, enhancing passenger safety and operational efficiency.

Related Products

- ALSTOM I/OBE2 12004-104-01 VER:V1.1.0: A complementary I/O bus extension module that extends the communication range of the I/OBUS2 12004-103-01 VER:V1.2.0 using differential signaling, ideal for long-distance signal transmission in railway yards.

- ALSTOM VLE3 12004-105-01 VER:V2.0.0: The Vehicle Logic Evaluation board that pairs with the I/OBUS2 to execute interlocking logic, providing real-time control and diagnostics for railway signaling systems.

- ALSTOM VIIB 12004-106-01 VER:V1.3.0: A dual-channel safety input board that interfaces with the I/OBUS2 to collect signals from track circuits and train detection sensors, ensuring accurate status monitoring.

- ALSTOM VOOB 12004-107-01 VER:V1.4.0: A safety output board that works with the I/OBUS2 to drive point machines, signals, and other actuators, featuring dual-redundant control for fail-safe operation.

- ALSTOM PWR 12004-108-01 VER:V1.0.0: A redundant power supply module that provides stable 24 V DC power to the I/OBUS2 and other iLOCK® components, ensuring uninterrupted system operation during voltage fluctuations.

- ALSTOM SDM 12004-109-01 VER:V1.5.0: A system diagnostic module that integrates with the I/OBUS2 to provide centralized monitoring, fault logging, and remote maintenance capabilities for railway signaling systems.

Installation and Maintenance

Installation Preparations:

Before installing the ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0, ensure the iLOCK® system is powered off and the DIN rail is securely mounted. Verify the 24 V DC power supply meets the module’s requirements (18–31.2 V DC) and use shielded cables to minimize EMI interference. Mount the module using the provided brackets, leaving adequate space for airflow. Connect the dual-redundant communication cables to the VLE board and I/O modules, following ALSTOM’s wiring diagrams to ensure correct pin assignments. Configure the module’s address and communication parameters via the iLOCK® system software, ensuring compatibility with the overall system architecture.

Before installing the ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0, ensure the iLOCK® system is powered off and the DIN rail is securely mounted. Verify the 24 V DC power supply meets the module’s requirements (18–31.2 V DC) and use shielded cables to minimize EMI interference. Mount the module using the provided brackets, leaving adequate space for airflow. Connect the dual-redundant communication cables to the VLE board and I/O modules, following ALSTOM’s wiring diagrams to ensure correct pin assignments. Configure the module’s address and communication parameters via the iLOCK® system software, ensuring compatibility with the overall system architecture.

Maintenance Recommendations:

Regularly inspect the module for physical damage, loose connections, or dust accumulation, particularly in high-vibration environments. Clean the enclosure with a dry, static-free cloth and check LED indicators for fault signals—e.g., a steady red light may indicate a communication failure. Perform quarterly firmware updates to access the latest security patches and system optimizations. For diagnostic purposes, use ALSTOM’s iLOCK® Maintenance Toolkit to monitor channel status, log faults, and perform loopback tests. In case of persistent issues, contact our technical support team for remote troubleshooting or module replacement. For preventive maintenance, schedule annual checks of communication cables and power supply integrity to ensure long-term reliability.

Regularly inspect the module for physical damage, loose connections, or dust accumulation, particularly in high-vibration environments. Clean the enclosure with a dry, static-free cloth and check LED indicators for fault signals—e.g., a steady red light may indicate a communication failure. Perform quarterly firmware updates to access the latest security patches and system optimizations. For diagnostic purposes, use ALSTOM’s iLOCK® Maintenance Toolkit to monitor channel status, log faults, and perform loopback tests. In case of persistent issues, contact our technical support team for remote troubleshooting or module replacement. For preventive maintenance, schedule annual checks of communication cables and power supply integrity to ensure long-term reliability.

Product Assurance

Our company provides a one-year quality warranty for the ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0, covering hardware failures due to non-human factors. During the warranty period, we will promptly replace any defective components at no additional cost. For discontinued models or urgent requirements, our global supply chain network leverages extensive inventory and strategic partnerships to fulfill orders within tight timelines, even for hard-to-find spare parts. With 17 years of expertise in industrial control distribution, we ensure that your systems benefit from the I/OBUS2 12004-103-01 VER:V1.2.0’s advanced capabilities, backed by our commitment to reliable service and technical support. Trust us to deliver solutions that enhance your operational efficiency and maintain the highest standards of railway signaling and industrial automation.

ALSTOM I/OBE2 12004-104-00 V1.0.0 Control board terminal

ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 Dual output module

ALSTOM POS1846 TRVC062333000 CP00000310 External control board terminates

ALSTOM STO1726KO1 Digital input terminal panel

ALSTOM VIIB16-C 12011-105-00 V1.0.0 board card

ALSTOM VOOB8-B 12004-106-04 VER:V1.0.0 DO card

ALSTOM VPS 12004-102-03 V1.0.0 Data collector

ALSTOM DSI1817 TRVC062335000 CP00003934 DCS/ Distributed control system

ALSTOM I/OBE2 12004-104-00 V1.0.0 Control board terminal

ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 Dual output module

ALSTOM POS1846 TRVC062333000 CP00000310 External control board terminates

ALSTOM STO1726KO1 Digital input terminal panel

ALSTOM VIIB16-C 12011-105-00 V1.0.0 board card

ALSTOM VOOB8-B 12004-106-04 VER:V1.0.0 DO card

ALSTOM VPS 12004-102-03 V1.0.0 Data collector

ALSTOM DSI1817 TRVC062335000 CP00003934 DCS/ Distributed control system

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: