Description

Product Overview

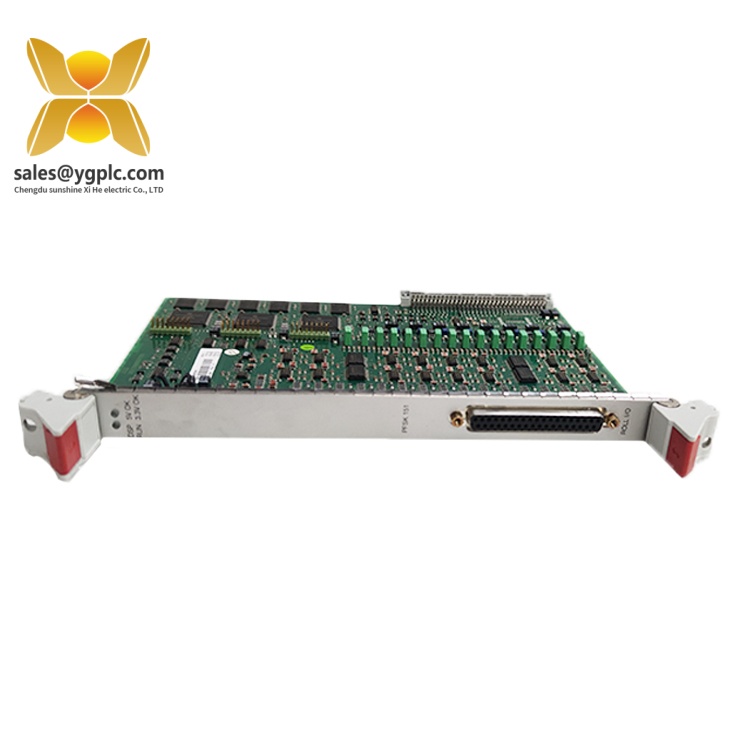

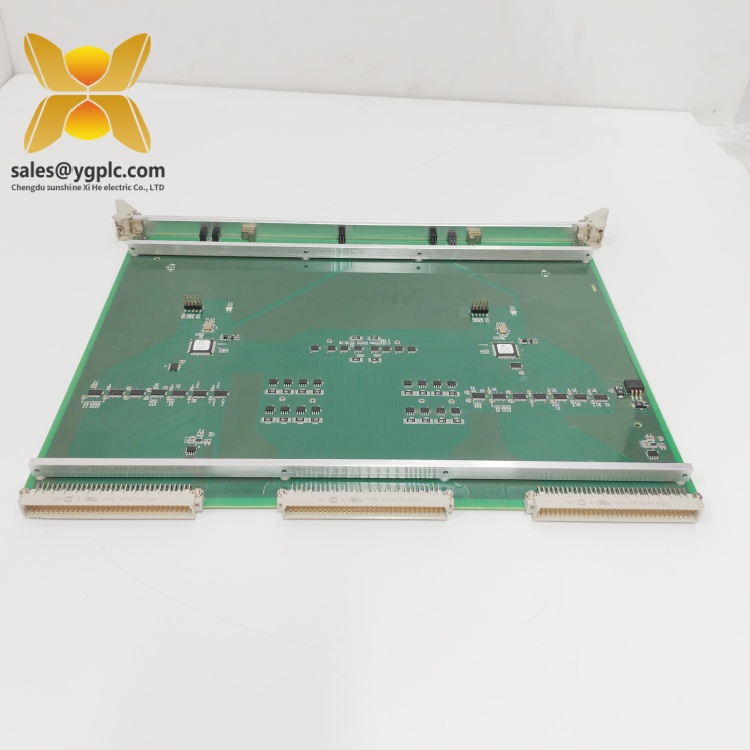

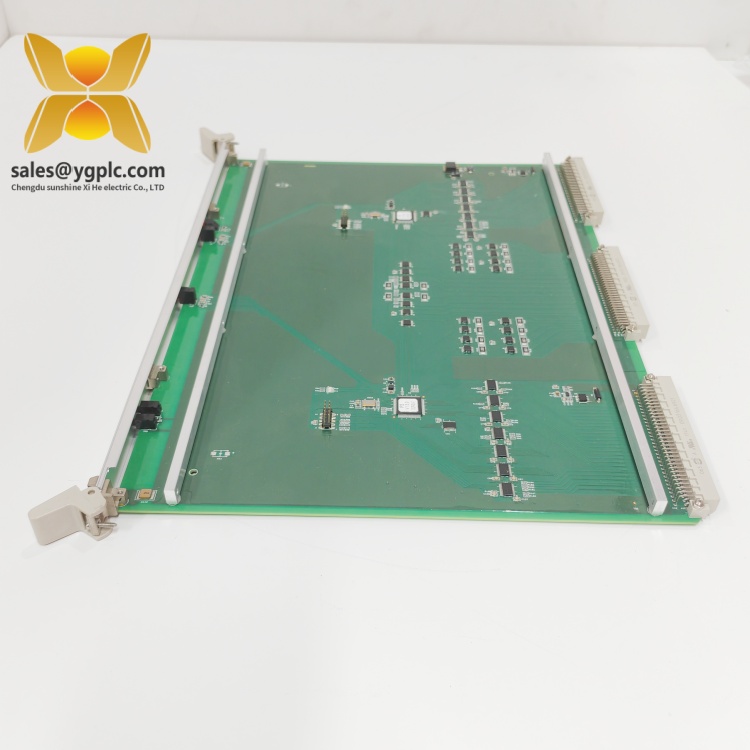

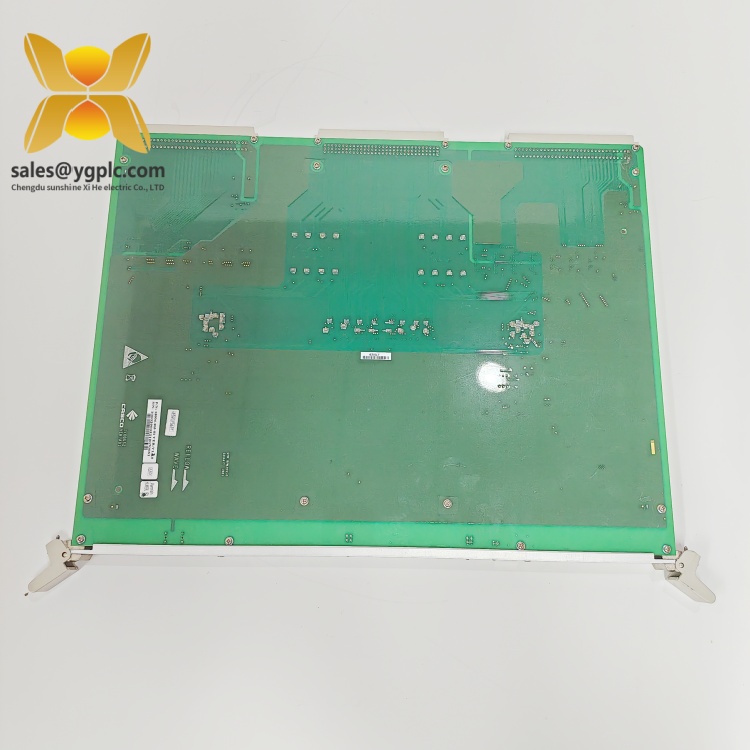

The ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 is a high-performance industrial automation module designed for critical control and monitoring applications within ALSTOM’s advanced distributed control systems (DCS). As a key component of ALSTOM’s modular I/O architecture, this module serves as a gateway for seamless integration between field devices and higher-level control systems, ensuring reliable data exchange and process optimization.

Engineered to handle diverse industrial environments, the ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 acts as an interface module, enabling bidirectional communication between analog/digital sensors/actuators and the central control unit. It supports a wide range of signal types, including 4-20mA analog inputs, discrete digital signals, and temperature measurements, making it suitable for complex process control scenarios. Belonging to ALSTOM’s robust I/O bus series, this module is optimized for compatibility with ALSTOM’s proprietary control platforms, ensuring seamless integration and interoperability.

In industrial automation systems, the ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 plays a pivotal role in bridging the gap between field-level devices and the control room. It processes raw data from sensors, converts it into actionable signals for actuators, and provides real-time diagnostics to maintain system integrity. Its high-speed data processing capabilities and redundant communication channels make it ideal for applications requiring precision and reliability, such as power generation, chemical processing, and water treatment plants. By reducing latency and enhancing data accuracy, this module contributes to improved operational efficiency and reduced downtime.Whatsapp:+86 18859254943.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 |

| Manufacturer | ALSTOM |

| Product Type | I/O Interface Module |

| Input Signal Types | Analog (4-20mA, 0-10V), Digital (TTL/Relay) |

| Output Signal Types | Analog (4-20mA, 0-10V), Digital (Relay) |

| Communication Protocol | PROFIBUS DP, MODBUS RTU, Ethernet |

| Operating Voltage | 24V DC ±10% |

| Power Consumption | ≤12W |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5%–95% non-condensing |

| Physical Dimensions | 200mm x 150mm x 80mm |

| Mounting Method | DIN-rail mountable |

| Redundancy Support | Dual-port communication |

| Channel Count | 16 inputs / 16 outputs |

I/OBUS2 12004-103-01 VER:V1.2.0

Main Features and Advantages

Multi-Protocol Compatibility

The ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 supports multiple industrial communication protocols, including PROFIBUS DP, MODBUS RTU, and Ethernet, ensuring flexibility in integrating with diverse automation systems. This versatility allows seamless interoperability with third-party devices and legacy systems, reducing the need for additional interface modules. For example, it can communicate with PLCs, HMIs, and SCADA systems, enabling centralized monitoring and control across complex industrial networks.

High Reliability and Redundancy

Designed for mission-critical applications, this module incorporates dual-port communication channels and robust error-checking mechanisms to prevent data loss or corruption. Its redundant power supply inputs and thermal protection features ensure stable operation even in harsh environments with voltage fluctuations or extreme temperatures. This reliability minimizes unplanned downtime, a critical factor in industries like power generation and oil refining where continuous operation is essential.

Flexible Signal Handling

With configurable input/output channels, the ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 accommodates a wide range of analog and digital signals. It supports hot-swappable modules, allowing maintenance without disrupting system operations. Additionally, built-in signal conditioning eliminates the need for external converters, simplifying system design and reducing costs. For instance, it can directly interface with pressure transmitters, temperature sensors, and motor starters, streamlining the integration process.

Advanced Diagnostics

The module includes real-time diagnostic capabilities that monitor signal integrity, power status, and communication health. Fault indicators and error logs help technicians quickly identify and resolve issues, minimizing troubleshooting time. This proactive approach to maintenance enhances system availability and reduces lifecycle costs by preventing minor faults from escalating into major failures.

I/OBUS2 12004-103-01 VER:V1.2.0

Application Areas

Power Generation

In thermal, hydro, and nuclear power plants, the ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 is used to monitor and control critical processes such as turbine operations, boiler feedwater regulation, and generator protection. Its high-speed data processing ensures precise synchronization of equipment, optimizing energy production and compliance with safety standards. For example, it can interface with pressure sensors in steam turbines to adjust valve positions and maintain stable output.

Chemical and Petrochemical Industries

In chemical processing plants, this module plays a vital role in managing reactor conditions, distillation columns, and safety interlocks. It processes analog signals from flow meters and pH sensors to regulate chemical dosing, ensuring product quality and operational safety. Its robust design withstands corrosive environments and high vibration, making it suitable for oil refineries and petrochemical facilities.

Water and Wastewater Treatment

The ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 is deployed in water treatment plants to control pump systems, monitor water quality parameters (e.g., turbidity, chlorine levels), and manage sludge processing. By integrating with SCADA systems, it enables remote monitoring and automation, improving efficiency and reducing manual intervention. In wastewater treatment, it ensures compliance with environmental regulations by optimizing treatment processes.Whatsapp:+86 18859254943.

Manufacturing and Process Automation

In discrete manufacturing, this module supports conveyor systems, robotic assembly lines, and quality control checkpoints. It interfaces with proximity sensors and actuators to coordinate production workflows, reduce cycle times, and enhance product consistency. Its modular design allows easy scalability, making it suitable for both small-scale production lines and large industrial complexes.

I/OBUS2 12004-103-01 VER:V1.2.0

Related Products

-

ALSTOM I/OBUS4 12004-104-01 VER:V2.0

A higher-capacity variant with 32 I/O channels, ideal for large-scale industrial applications requiring extensive signal processing. It shares the same communication protocols but offers increased throughput and redundancy. -

ALSTOM I/OBUS2-RS485 12004-103-02 VER:V1.3

A specialized version with RS485 interface support, designed for legacy systems or environments where long-distance communication is required. It complements the standard I/OBUS2 by expanding connectivity options. -

ALSTOM I/OBUS2-Ex 12004-103-03 VER:V1.1

An explosion-proof variant certified for hazardous environments, commonly used in oil and gas production. It maintains the core functionality of the I/OBUS2 while meeting stringent safety standards. -

ALSTOM I/OBUS2-PWR 12004-103-04 VER:V1.0

A power-enhanced module with integrated surge protection, suitable for applications with unstable power supplies. It ensures reliable operation in regions prone to voltage fluctuations. -

ALSTOM I/OBUS2-ETH 12004-103-05 VER:V1.4

A version optimized for Ethernet-based networks, offering high-speed data transfer and compatibility with modern industrial IoT platforms. It supports OPC UA and MQTT protocols for advanced analytics and remote monitoring.

Installation and Maintenance

Installation Preparations:

Before installing the ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0, ensure the power supply is disconnected and the DIN-rail is securely mounted. Verify the module’s compatibility with the control system’s communication protocols and configure the appropriate signal settings (e.g., analog ranges, digital logic) using ALSTOM’s proprietary software. Connect the power cables and communication buses following the wiring diagram provided in the product manual, ensuring all connections are shielded to minimize electromagnetic interference.

Before installing the ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0, ensure the power supply is disconnected and the DIN-rail is securely mounted. Verify the module’s compatibility with the control system’s communication protocols and configure the appropriate signal settings (e.g., analog ranges, digital logic) using ALSTOM’s proprietary software. Connect the power cables and communication buses following the wiring diagram provided in the product manual, ensuring all connections are shielded to minimize electromagnetic interference.

I/OBUS2 12004-103-01 VER:V1.2.0

Maintenance Recommendations:

Regularly inspect the module for physical damage, loose connections, or signs of corrosion. Clean dust and debris from the enclosure using a non-static cloth to maintain optimal thermal performance. Monitor the module’s diagnostic indicators for errors or nonormal. Perform firmware updates as recommended by ALSTOM to address security vulnerabilities and improve functionality. For preventive maintenance, replace the module’s battery (if applicable) every 3–5 years to ensure data retention during power outages.E-mail :sales@ygplc.com.

Regularly inspect the module for physical damage, loose connections, or signs of corrosion. Clean dust and debris from the enclosure using a non-static cloth to maintain optimal thermal performance. Monitor the module’s diagnostic indicators for errors or nonormal. Perform firmware updates as recommended by ALSTOM to address security vulnerabilities and improve functionality. For preventive maintenance, replace the module’s battery (if applicable) every 3–5 years to ensure data retention during power outages.E-mail :sales@ygplc.com.

Product Assurance

Our company provides a one-year quality warranty for the ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0, covering hardware failures due to non-human factors. During this period, if the product shows any performance anomalies or functional failures, we will promptly provide replacement services. For discontinued models or urgent needs, our global supply chain network enables rapid response to customers’ requests for scarce spare parts. With 17 years of experience in the industrial control industry, we are committed to ensuring that the ALSTOM I/OBUS2 12004-103-01 VER:V1.2.0 and all products we sell contribute to the stable and continuous operation of industrial systems.

ALSTOM CMP1838 TRVCO62345000 CP00005202 Power source

ALSTOM DSI1817 TRVC062335000 CP00003934 base

ALSTOM I/OBE2 12004-104-00 V1.0.0 exchange

Elmo G-TUB30-480ERSS0 Tachometer sensor

Woodward 8237-1369 modbus card

Woodward 8237-1600 Power strip

ABB 500TRM02 1MRB150011R0001 Control panel

Elmo G-TUB30-480ERSS0 Double output

GE UCSC H1 IS420UCSCH1A-B Expansion module

GE 1S420ESWBH3A RXM rack

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: