Description

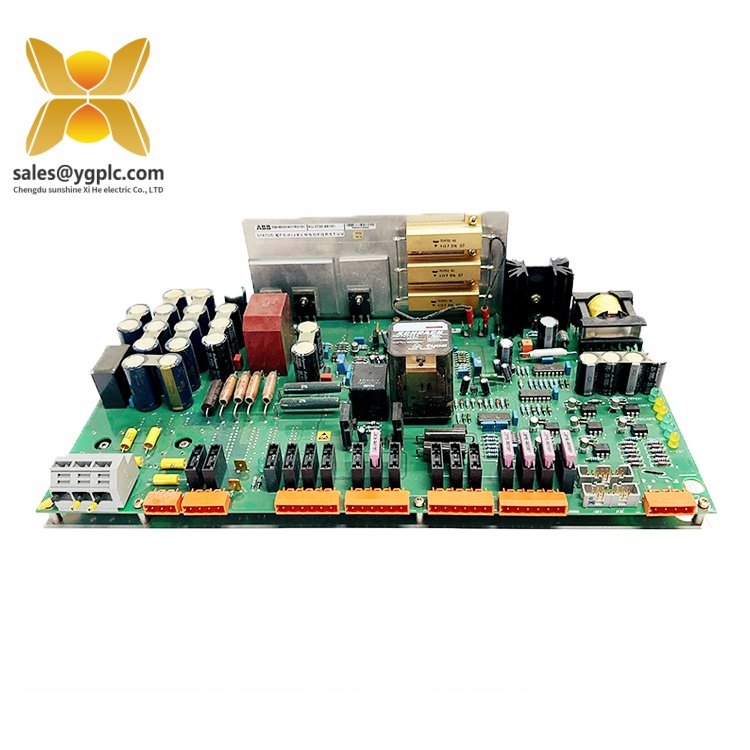

Product Overview :ABB PM511V16 3BSE011181R1

Technical Specifications :ABB PM511V16 3BSE011181R1

| Parameter Name | Parameter Value |

|---|---|

| Product Model | PM511V16 3BSE011181R1 |

| Manufacturer | ABB |

| Product Type | PLC Module (Central Processing Unit) |

| Processor | 32-bit RISC CPU |

| User Memory | 16 MB (expandable via SD card) |

| I/O Capacity | Up to 10,000 points (via expansion modules) |

| Communication Ports | 2 × Ethernet (10/100 Mbps), 1 × RS-485 |

| Power Supply | 24 V DC ±20% (with reverse polarity protection) |

| Physical Dimensions | 100 mm (H) × 160 mm (W) × 80 mm (D) |

| Weight | 0.8 kg |

| Operating Temperature | -25°C to +70°C |

| Mounting | DIN rail (35 mm) |

| Certifications | CE, UL, IEC 61131-2, ATEX (for hazardous areas) |

PM511V16 3BSE011181R1

Key Features and Advantages :ABB PM511V16 3BSE011181R1

Redundancy Support: While the PM511V16 3BSE011181R1 is designed for standalone operation, it can be paired with a redundant CPU module (e.g., PM590-ETH) to create fail-safe systems, ensuring continuous operation in mission-critical applications like power generation or oil refining.

PM511V16 3BSE011181R1

Application Areas :ABB PM511V16 3BSE011181R1

- Manufacturing: Controls assembly lines, packaging machines, and quality inspection systems, ensuring precision and consistency in automotive, food & beverage, and electronics production. For example, it can manage robotic pick-and-place operations, monitor machine status via IoT sensors, and trigger alarms for maintenance needs.

- Energy & Utilities: Manages power distribution systems, renewable energy inverters, and water treatment plants. In solar farms, the module coordinates inverter outputs, monitors grid connectivity, and initiates shutdown protocols during faults. In wastewater facilities, it controls pump sequences and monitors chemical dosing for compliance with environmental standards.

- Oil & Gas: Optimizes wellhead operations, pipeline monitoring, and refinery processes. The PM511V16 3BSE011181R1 can integrate with pressure sensors, flow meters, and safety interlocks, ensuring safe and efficient extraction, transportation, and refining of hydrocarbons.

- Transportation: Powers automation in smart logistics hubs, including conveyor networks, baggage handling systems, and tunnel ventilation controls. Its reliability is critical for 24/7 operations in airports and freight terminals.

- Machine Automation: Controlling CNC machines, presses, and robotic arms, with real-time feedback from encoders and vision systems.

- Building Automation: Managing HVAC systems, lighting controls, and energy management in commercial buildings, optimizing energy use and occupant comfort.

- Process Control: Orchestrating batch processes in chemical plants, such as reactor temperature regulation and valve sequencing, while maintaining compliance with safety standards.

PM511V16 3BSE011181R1

Related Products :ABB PM511V16 3BSE011181R1

- PM510V16 3BSE011180R1: A lower-cost variant with 8 MB memory, suitable for smaller-scale applications requiring basic logic control.

- PM590-ETH 3BSE066192R1: A redundant CPU module that pairs with the PM511V16 3BSE011181R1 to create high-availability systems for critical infrastructure.

- DI521 3BSE018190R1: A digital input module (16 channels, 24 V DC) for expanding the module’s discrete signal acquisition capabilities.

- DO521 3BSE018191R1: A digital output module (16 channels, 24 V DC/2 A) for controlling actuators and relays.

- AI523 3BSE018200R1: An analog input module (8 channels, 0–10 V/4–20 mA) for process variable monitoring, such as temperature or pressure.

- CM578-ETH 3BSE050105R1: A communication module supporting Profibus DP, enabling integration with legacy systems.

- PS501 3BSE018167R1: A redundant 24 V DC power supply for the AC 500 Series, ensuring stable power delivery to the PM511V16 3BSE011181R1.

- TB521 3BSE018184R1: A terminal block module for simplifying field wiring connections to I/O modules.

Installation and Maintenance :ABB PM511V16 3BSE011181R1

Before installing the ABB PM511V16 3BSE011181R1, ensure the DIN rail is securely mounted in a grounded control panel. Verify the power supply (24 V DC) meets voltage and ripple requirements, and use shielded cables for communication and I/O connections to minimize electromagnetic interference. Mount the module vertically, leaving 20 mm of clearance on all sides for heat dissipation. Configure the module’s IP address and communication parameters using Control Builder PM before powering it on.

- Routine Inspections: Monthly checks should include verifying LED status indicators (power, communication, error), tightening terminal connections, and cleaning dust from the enclosure using a static-free cloth.

- Firmware Updates: Periodically update the module’s firmware via Control Builder PM to access new features and security patches. Back up project files before updating to prevent data loss.

- Spare Parts Management: Maintain a spare PM511V16 3BSE011181R1 in a controlled environment (10–30°C, 20–80% RH) with anti-static packaging. Regularly test spare modules to ensure functionality.

- System Backups: Weekly backups of the module’s program and configuration data are essential for rapid recovery in case of hardware failure. Use the module’s SD card slot for offline backups.

PM511V16 3BSE011181R1

Product Warranty :ABB PM511V16 3BSE011181R1

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

ABB UDD406A FIM card

ABB PPC905AE101 3BHE014070R0101 Communication input interface component

ABB SA811F Communication output interface component

ABB REM610 Module connector

ABB CS513 3BSE000435R1 Double output

ABB 3ASC25H204 DAPU100 DCS module

ABB 3ASC25H219B DATX133 AO card

ABB 3BDH000741R1 CTI 21-P EX Digital input terminal board

ABB APBU-44C 64669982 Universal digital input terminals

ABB SC520 3BSE003816R1 Control panel

ABB 216DB61 HESG324063R100/J Control processor

ABB 216EA62 1MRB150083R1/F 1MRB178066R1/F Switch quantity input card

ABB UFC718AE101 HIEE300936R0101 Enhanced intelligent communication module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: