Description

Main Features and Advantages

High – Speed Data Transmission: The ABB 500TRM02 1MRB150011R1 is engineered to offer high – speed data transfer capabilities. This is of utmost importance in industrial applications where real – time monitoring and control are critical. For example, in a fast – paced manufacturing line, quick data transmission ensures that any changes in the production process can be immediately detected and addressed. The module’s ability to transfer data at high speeds enables operators to respond promptly to any anomalies, minimizing the risk of production delays or quality issues.

Reliable Connectivity: It provides reliable connectivity between diverse industrial devices. In an industrial environment filled with various types of equipment, from sensors that detect temperature and pressure to actuators that control machinery, the 500TRM02 1MRB150011R1 ensures that all these devices can communicate effectively. This reliability is achieved through its robust design and advanced communication technology, which can withstand the harsh conditions often found in industrial settings, such as electrical interference and vibrations.

Flexible Configuration: The coupler module offers flexible configuration options. Users can adapt it to different industrial setups based on their specific requirements. Whether it is a small – scale industrial operation or a large – scale plant with multiple production lines, the ABB 500TRM02 1MRB150011R1 can be configured to support the necessary number of devices and communication protocols. This flexibility not only makes it suitable for a wide range of applications but also allows for easy expansion or modification of the industrial automation system as the business grows or the production process changes.

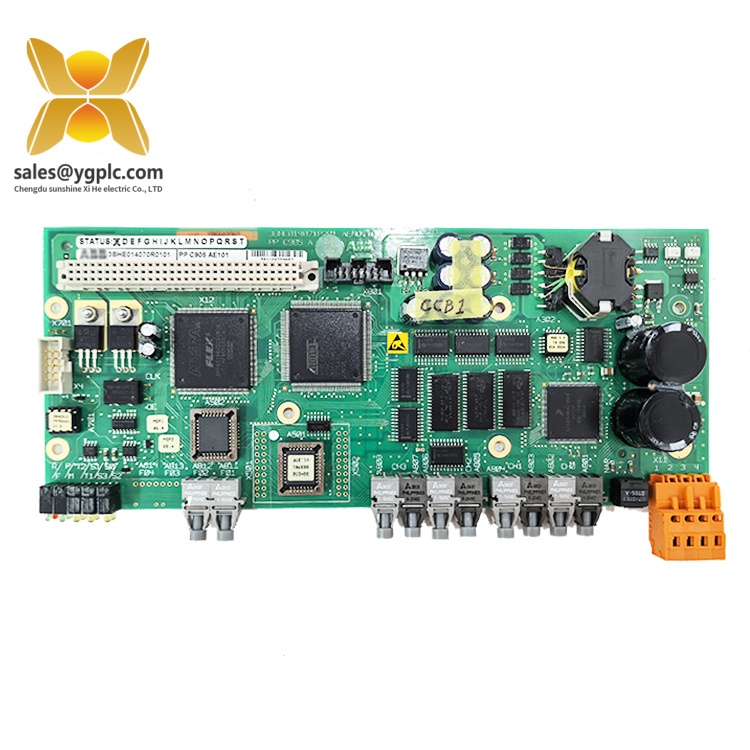

500TRM02 1MRB150011R1

Compatibility: It is highly compatible with other ABB products as well as many third – party industrial devices. This compatibility simplifies the integration process in industrial networks. For instance, when upgrading an existing industrial automation system, the 500TRM02 1MRB150011R1 can be easily incorporated without major re – engineering efforts. It can work seamlessly with ABB’s DCS components, as well as with sensors and actuators from other manufacturers that follow standard industrial communication protocols.

Application Areas

Manufacturing Industry: In manufacturing plants, the ABB 500TRM02 1MRB150011R1 is extensively used. It connects the programmable logic controllers (PLCs) to various sensors and actuators on the production line. For example, in an automotive manufacturing plant, it can link the PLC that controls the assembly process to sensors that detect the position of car parts during assembly. This ensures that the assembly robots can accurately pick and place the parts, leading to a smooth and efficient production process. In a food and beverage manufacturing facility, the module can be used to connect the control system to sensors that monitor the filling levels of bottles, ensuring accurate filling and minimizing product waste.

Process Control Industry: In industries such as oil and gas, chemical, and power generation, process control is of vital importance. The 500TRM02 1MRB150011R1 is used to connect different control devices in the process control system. In an oil refinery, it can link the distributed control system to sensors that measure the temperature, pressure, and flow rate of oil and gas streams. Based on the data received, the control system can adjust the operation of pumps, valves, and other equipment to optimize the refining process. In a power generation plant, the module helps in connecting the control system to sensors that monitor the performance of turbines and generators, ensuring stable power generation.

Smart Buildings: In smart building applications, the ABB 500TRM02 1MRB150011R1 can be used to integrate different building management systems. It can connect the heating, ventilation, and air – conditioning (HVAC) system to sensors that detect temperature, humidity, and occupancy levels in different areas of the building. This allows for intelligent control of the HVAC system, reducing energy consumption. Additionally, it can be used to connect security systems, such as cameras and access control devices, to the overall building management system, providing a comprehensive and integrated solution for building management.

500TRM02 1MRB150011R1

Related Products

- ABB 500SCM01 1MRB150004R1: This is also a coupler module from ABB, similar to the 500TRM02 1MRB150011R1. However, it may have different communication capabilities or be better suited for specific types of industrial networks. It can be used as an alternative or in combination with the 500TRM02 1MRB150011R1 depending on the complexity and requirements of the automation system.

- ABB 1KHL015502R0004 (N4BDTEBIT): Another coupler module with its own unique features. It might have different power requirements or be designed to work with a specific subset of industrial devices. It can be considered for applications where the 500TRM02 1MRB150011R1 may not fully meet the specific communication or compatibility needs.

- ABB DCS Input/Output Modules: These modules work in tandem with the 500TRM02 1MRB150011R1. They provide the interface for connecting sensors and actuators to the DCS. For example, digital input modules can receive signals from switches and relays, while analog output modules can send control signals to devices like variable – speed drives.

- ABB Communication Interface Modules: Modules such as those for PROFINET or EtherCAT communication. They can be added to the system along with the 500TRM02 1MRB150011R1 to expand the communication capabilities, enabling connection to a wider range of industrial devices that use these specific communication protocols.

- ABB Power Supply Modules: Essential for providing a stable power source to the 500TRM02 1MRB150011R1 and other components in the system. Different power supply modules can offer various voltage outputs and power ratings, ensuring compatibility with the overall system requirements.

Installation and Maintenance

Installation Preparations: Before installing the ABB 500TRM02 1MRB150011R1, ensure that the power to the entire industrial automation system is switched off. Check the DIN – rail where it will be mounted to ensure it is in good condition and has enough space to accommodate the module. Verify the compatibility of the module with other components in the system, including the power supply and communication interfaces. Follow the wiring diagram provided in the product manual meticulously when connecting the power cables and communication lines. Make sure all connections are secure to prevent any loose connections that could lead to communication failures or power – related issues.

500TRM02 1MRB150011R1

Maintenance Recommendations: Regularly inspect the 500TRM02 1MRB150011R1 for any signs of physical damage, such as cracks in the enclosure or loose screws. Clean the module periodically to remove dust and debris, as these can affect its performance, especially in high – temperature environments. Monitor the operating temperature of the module and ensure it remains within the specified range. Check the communication status with other devices in the network regularly to detect any potential communication problems. If any faults are detected, refer to the troubleshooting guide in the product manual. In case of persistent issues, contact ABB’s technical support or our company’s experienced technicians for assistance.

Product Assurance

Our company provides a one – year quality warranty for the ABB 500TRM02 1MRB150011R1, covering hardware failures due to non – human factors. During this period, if the product shows any performance anomalies or functional failures, we will promptly provide replacement services. For discontinued models or in case of urgent needs, our extensive global supply chain network enables us to quickly respond to customers’ requests for scarce spare parts. With 17 years of experience in the industrial control industry, we are committed to ensuring that the ABB 500TRM02 1MRB150011R1 and all the products we sell contribute to the stable and continuous operation of industrial systems.

ABB 500B0M01 1MRB150023R0002 governor

ABB 500MBA02 1MRB150003R000B Input module

ABB PM864AK01 3BSE01816R1 Servo valve

ABB 500CPU03 1HDF700003R5122 Analog input

ABB 500AIM02 1MRB150022 R0002Y 1HDF 930412 X010 governor

ABB 500B0M01 1MRB150023R0002 governor

ABB 500MBA02 1MRB150003R000B Input module

ABB PM864AK01 3BSE01816R1 Servo valve

ABB 500CPU03 1HDF700003R5122 Analog input

ABB 500AIM02 1MRB150022 R0002Y 1HDF 930412 X010 governor

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: