Description

Product Overview

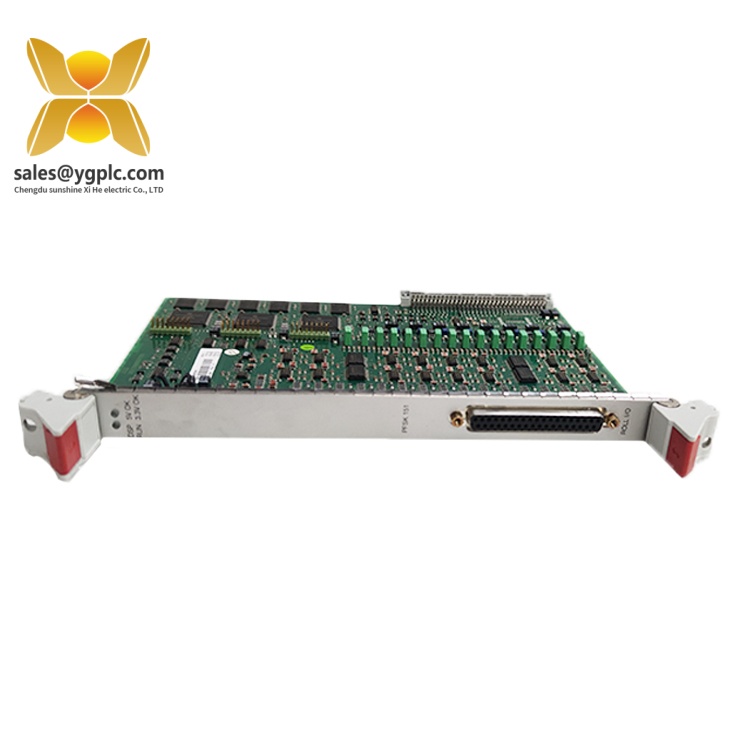

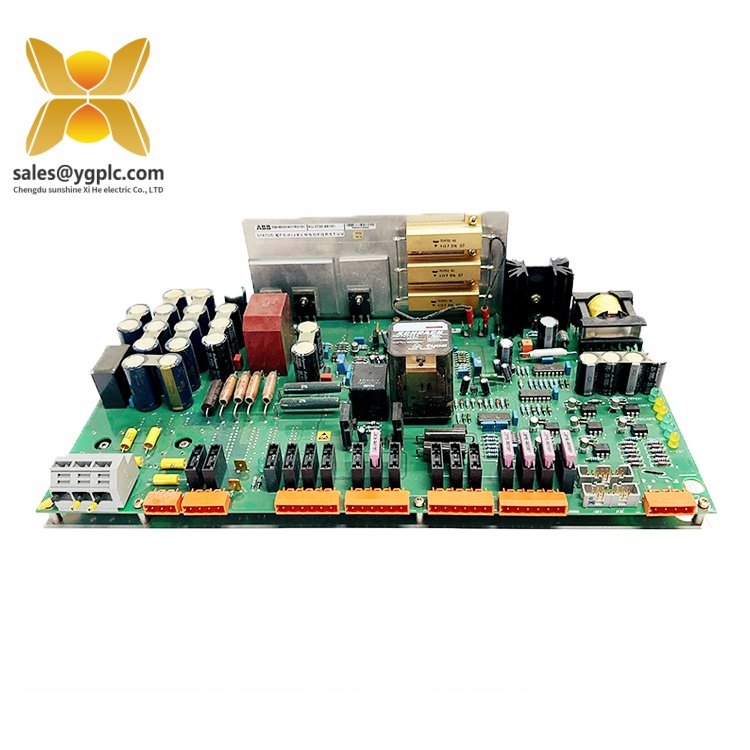

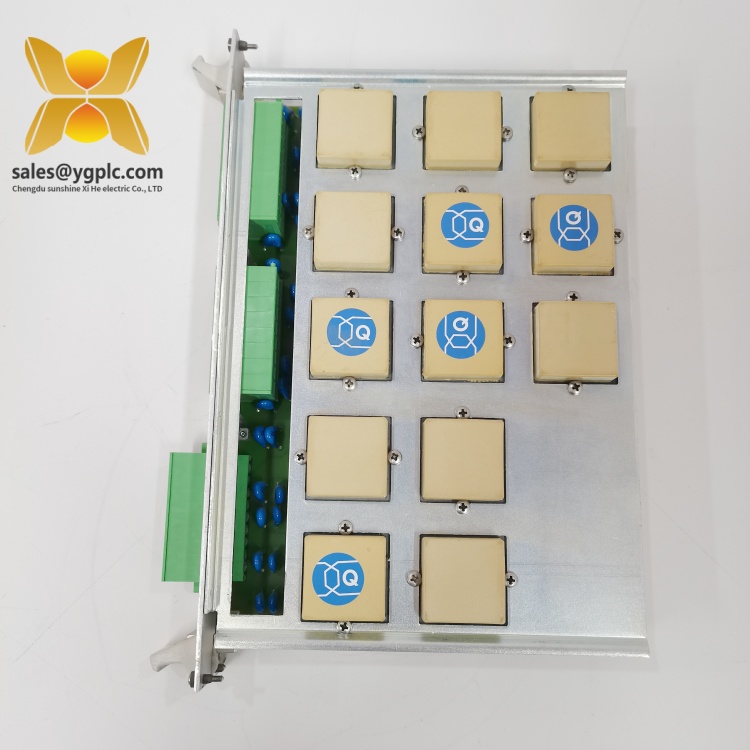

The ABB 500MTM02 1MRB150020R0712 1HDF 930512 X010 is a high-precision temperature measurement module designed to deliver accurate and reliable temperature data acquisition in industrial automation systems. As a key component of ABB’s AC500 series, this module is engineered to interface with a wide range of temperature sensors, making it an essential solution for process control, machinery monitoring, and energy management applications.

The ABB 500MTM02 1MRB150020R0712 1HDF 930512 X010 serves as a critical link between field – mounted temperature sensors and higher – level control systems, converting raw sensor signals into standardized output signals for further processing. It supports multiple sensor types, including thermocouples (TC) and resistance temperature detectors (RTD), ensuring compatibility with diverse industrial setups. With its advanced signal conditioning and digital processing capabilities, the module minimizes measurement errors and noise interference, providing users with precise temperature data essential for informed decision – making in industrial processes.Whatsapp:+86 18859254943.

Belonging to ABB’s renowned AC500 family, the 500MTM02 1MRB150020R0712 1HDF 930512 X010 is built for seamless integration into modular control systems. It acts as a foundational element in distributed control architectures, enabling real – time monitoring of temperature – sensitive processes. Whether deployed in a manufacturing plant, a power generation facility, or a chemical processing unit, this module enhances system reliability by providing consistent and accurate temperature measurements, thereby contributing to optimized process efficiency and equipment protection.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 500MTM02 1MRB150020R0712 1HDF 930512 X010 |

| Manufacturer | ABB |

| Product Type | Temperature Measurement Module (Multi – channel, Universal Input) |

| Input Types | Thermocouples (K, J, T, E, R, S, B, N), RTDs (Pt100, Pt1000, Ni100, Ni1000), Ohmic inputs (0 – 500Ω), Voltage inputs (0 – 10V, ±10V) |

| Number of Channels | 8 isolated channels |

| Resolution | 16 – bit for RTD/thermocouple inputs, 14 – bit for voltage/ohmic inputs |

| Accuracy | ±0.1% of full scale (RTD), ±0.2% of full scale (thermocouple) |

| Communication Protocols | Modbus RTU (RS485), Ethernet (TCP/IP, Modbus TCP) |

| Power Supply | 24 V DC (±10%), isolated |

| Power Consumption | ≤3 W (without load) |

| Operating Temperature | – 20°C to + 60°C (ambient, derated at high loads) |

| Storage Temperature | – 40°C to + 85°C |

| Humidity | 5% – 95% non – condensing |

| Physical Dimensions | 120 mm (W) × 110 mm (H) × 80 mm (D) |

| Mounting Method | DIN – rail mountable (35 mm, EN 60715) |

| Isolation Rating | 500 V DC between channels and power supply |

| Update Rate | 100 ms per channel (max.) |

500MTM02 1MRB150020R0712

Main Features and Advantages

Universal Input Flexibility

The ABB 500MTM02 1MRB150020R0712 1HDF 930512 X010 stands out for its ability to accept a wide array of temperature sensor inputs. It supports all common thermocouple types and RTD configurations, eliminating the need for multiple specialized modules. This versatility allows users to standardize their temperature measurement setup, reducing inventory complexity and installation costs. For example, in a chemical plant with a mix of RTDs for tank temperature monitoring and thermocouples for reactor control, the module can seamlessly handle both sensor types, simplifying system integration.

High – Precision Measurement

Engineered with advanced analog – to – digital conversion technology, the module delivers exceptional measurement precision. The 16 – bit resolution for RTD inputs ensures minimal error margins, even in low – temperature gradients, while the robust signal conditioning circuitry filters out electromagnetic interference (EMI) and radio – frequency interference (RFI). This precision is critical in applications such as pharmaceutical manufacturing, where strict temperature control is non – negotiable for product quality and safety.

Robust Industrial Design

Built to withstand harsh industrial environments, the 500MTM02 1MRB150020R0712 1HDF 930512 X010 features a rugged enclosure with conformal coating, protecting against dust, moisture, and vibrations. Its wide operating temperature range makes it suitable for extreme environments, from sub – zero industrial freezers to high – temperature furnaces. The isolated channels and 500 V DC isolation rating further enhance reliability by preventing ground loops and voltage spikes, ensuring stable operation in electrically noisy settings such as power substations or motor control centers.

Seamless System Integration

As part of the AC500 series, the module integrates effortlessly with ABB’s control platforms and third – party systems via Modbus RTU and Ethernet protocols. The Modbus TCP support enables high – speed data transfer to supervisory control and data acquisition (SCADA) systems, while the RS485 interface ensures compatibility with legacy setups. This dual – protocol capability makes it ideal for both greenfield projects and retrofitting existing infrastructure, providing future – proof connectivity for evolving industrial automation needs.

500MTM02 1MRB150020R0712

Advanced Diagnostic Capabilities

The module includes real – time diagnostics to monitor sensor health and signal integrity. LED indicators on the front panel provide instant feedback on power status, channel errors, and communication faults. Additionally, built – in self – test (BIST) functionality detects anomalies such as open circuits, short circuits, or sensor drift, enabling proactive maintenance and reducing downtime. In a power plant, for example, these diagnostics can quickly identify a failing RTD in a turbine bearing, allowing timely replacement before a critical failure occurs.Whatsapp:+86 18859254943.

Application Areas

Manufacturing Industry

In manufacturing plants, the ABB 500MTM02 1MRB150020R0712 1HDF 930512 X010 is used to monitor temperature in critical processes such as injection molding, heat treatment, and conveyor systems. For instance, in an automotive assembly plant, it can measure the temperature of mold cavities in real time, ensuring consistent part quality by detecting deviations that could lead to defects. The module’s high update rate allows for rapid response to temperature fluctuations, supporting just – in – time manufacturing demands.

Energy Sector

In power generation, the module plays a vital role in monitoring equipment health. It measures stator and rotor temperatures in generators, transformer oil temperatures, and cooling system performance in thermal, hydro, and wind power plants. In a wind turbine, for example, it can detect overheating in gearboxes or generators, triggering alarms to prevent costly breakdowns. Its compatibility with remote monitoring systems via Ethernet enables centralized control room operations, enhancing grid stability and maintenance efficiency.

Chemical and Petrochemical

Chemical processing plants rely on the 500MTM02 1MRB150020R0712 1HDF 930512 X010 to control exothermic reactions, distillation columns, and storage tanks. It accurately measures temperature profiles in reactors, ensuring safe operation within predefined limits. In a refinery, the module can monitor the temperature of crude oil during distillation, optimizing energy usage and preventing over – temperature events that could compromise product quality or safety.

500MTM02 1MRB150020R0712

Pharmaceutical and Biotechnology

In pharmaceutical manufacturing, precise temperature control is essential for processes like fermentation, lyophilization, and storage of active ingredients. The module’s high accuracy and compliance with industry standards make it suitable for monitoring autoclaves, cold storage units, and bioreactors. It ensures that temperature – sensitive processes adhere to strict regulatory requirements, such as those outlined in Good Manufacturing Practice (GMP), by providing traceable and reliable data.

Water and Wastewater Treatment

The module is used in water treatment plants to monitor temperatures in clarifiers, disinfection units, and sludge digesters. It helps optimize the performance of heating systems in wastewater treatment, ensuring efficient biological processes while preventing overheating of pumps and blowers. In desalination plants, it measures the temperature of seawater and brine streams, supporting the efficient operation of reverse osmosis membranes.

Related Products

- ABB 500MTM01 1MRB150019R0711 1HDF 930511 X010: A single – channel version of the 500MTM02 1MRB150020R0712 1HDF 930512 X010, suitable for smaller applications requiring fewer temperature measurement points while maintaining the same input flexibility and precision.

- ABB 500CTM02 1MRB150021R0713 1HDF 930513 X010: A complementary current measurement module in the AC500 series, designed to work alongside the 500MTM02 1MRB150020R0712 1HDF 930512 X010 for combined temperature and current monitoring in motor control applications.

- ABB 500COMM01 1MRB150001R0701 1HDF 930501 X010: A communication gateway module that expands the network capabilities of the 500MTM02 1MRB150020R0712 1HDF 930512 X010, supporting protocols like Profibus DP and EtherNet/IP for integration with complex industrial networks.

- ABB 500PWR01 1MRB150005R0705 1HDF 930505 X010: A dedicated 24 V DC power supply module optimized for the AC500 series, ensuring stable power delivery to the 500MTM02 1MRB150020R0712 1HDF 930512 X010 and other connected devices in harsh power environments.

- ABB 500DI08 1MRB150008R0708 1HDF 930508 X010: A digital input module that can be paired with the 500MTM02 1MRB150020R0712 1HDF 930512 X010 to capture status signals from switches and sensors, enabling comprehensive process control and monitoring.

- ABB 500AO04 1MRB150004R0704 1HDF 930504 X010: An analog output module that works in tandem with the 500MTM02 1MRB150020R0712 1HDF 930512 X010 to send control signals to actuators, forming a complete closed – loop temperature control system.

Installation and Maintenance

Installation Preparations:

Before installing the ABB 500MTM02 1MRB150020R0712 1HDF 930512 X010, ensure the power to the control system is switched off. Mount the module on a 35 mm DIN – rail in a suitable control cabinet, ensuring adequate ventilation to maintain optimal operating temperatures. Connect the power supply using shielded cables to prevent EMI interference, ensuring the 24 V DC input matches the module’s requirements. For sensor connections, use twisted – pair cables for thermocouples and RTDs to minimize noise, and terminate each channel according to the sensor type (e.g., 3 – wire for RTDs, 2 – wire for thermocouples). Finally, configure the module via ABB’s Control Builder software, selecting the appropriate input type and calibration parameters for each channel.

Before installing the ABB 500MTM02 1MRB150020R0712 1HDF 930512 X010, ensure the power to the control system is switched off. Mount the module on a 35 mm DIN – rail in a suitable control cabinet, ensuring adequate ventilation to maintain optimal operating temperatures. Connect the power supply using shielded cables to prevent EMI interference, ensuring the 24 V DC input matches the module’s requirements. For sensor connections, use twisted – pair cables for thermocouples and RTDs to minimize noise, and terminate each channel according to the sensor type (e.g., 3 – wire for RTDs, 2 – wire for thermocouples). Finally, configure the module via ABB’s Control Builder software, selecting the appropriate input type and calibration parameters for each channel.

500MTM02 1MRB150020R0712

Maintenance Recommendations:

Regularly inspect the 500MTM02 1MRB150020R0712 1HDF 930512 X010 for loose connections or physical damage, tightening terminal screws and cleaning the enclosure with a dry, static – free cloth to remove dust buildup. Monitor the LED indicators for any fault signals: a red light may indicate a sensor failure or communication error, while a blinking green light suggests a temporary anomaly. Use the module’s diagnostic software to review channel status and historical data, identifying trends such as gradual sensor drift that may require recalibration. For firmware updates, download the latest version from ABB’s support portal and follow the step – by – step guide to ensure compatibility and access to new features. In the event of a persistent fault, contact our technical support team for assistance, leveraging our expertise in industrial control hardware to resolve issues promptly.Whatsapp:+86 18859254943.

Regularly inspect the 500MTM02 1MRB150020R0712 1HDF 930512 X010 for loose connections or physical damage, tightening terminal screws and cleaning the enclosure with a dry, static – free cloth to remove dust buildup. Monitor the LED indicators for any fault signals: a red light may indicate a sensor failure or communication error, while a blinking green light suggests a temporary anomaly. Use the module’s diagnostic software to review channel status and historical data, identifying trends such as gradual sensor drift that may require recalibration. For firmware updates, download the latest version from ABB’s support portal and follow the step – by – step guide to ensure compatibility and access to new features. In the event of a persistent fault, contact our technical support team for assistance, leveraging our expertise in industrial control hardware to resolve issues promptly.Whatsapp:+86 18859254943.

Product Assurance

Our company provides a one – year quality warranty for the ABB 500MTM02 1MRB150020R0712 1HDF 930512 X010, covering all hardware failures resulting from non – human factors. During this period, if the product experiences performance irregularities or functional failures, we will promptly provide a replacement to minimize downtime. For discontinued models or urgent requirements, our global supply chain network is equipped to source and deliver scarce spare parts efficiently, leveraging 17 years of industry experience to meet even the most time – critical needs. We are committed to ensuring the reliability of your industrial systems, offering not just products but also dedicated support to keep your operations running smoothly. Trust us to be your partner in maintaining the precision and stability of your temperature monitoring and control applications, backed by our unwavering focus on quality and customer satisfaction.E-mail :sales@ygplc.com.

ABB 500BIM01 1MRB150024R0002 Card module

ABB 500BIO01 1MRB150005R0001 1MRB200060/E DCS card

ABB 500BOM01 1MRB150023R0002 DI card

ABB 500CMP04 HE401314-0001 1MRB150051R1 controller

ABB 500CPU03 1HDF700003R5122 Inverter operating panel

ABB 500TRM02 1MRB150011R1 Communication module

ABB 500AIM02 1MRB150022 R0002Y 1HDF 930412 X010 Frequency converter module

ABB 500PB101 1MRB178009R0001 1MRB200064/C System module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: