Description

ABB 500CIM05 1MRB150077R1B Communication Interface Module

Product Overview:ABB 500CIM05 1MRB150077R1B

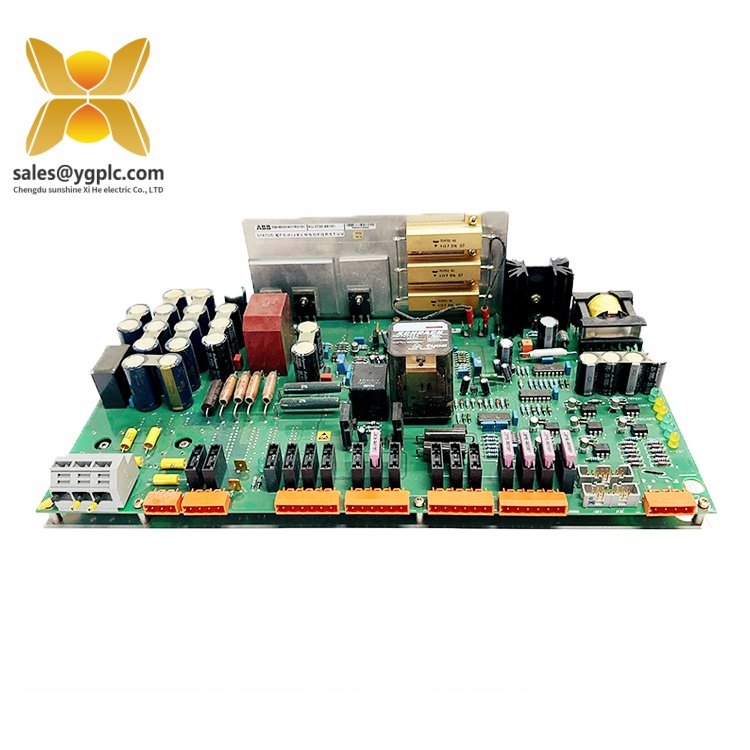

The ABB 500CIM05 1MRB150077R1B is a high-performance Communication Interface Module designed for industrial automation systems, serving as a critical link in ABB’s AC500 Series programmable logic controller (PLC) platform. Engineered to facilitate seamless data exchange between PLCs, human-machine interfaces (HMIs), and higher-level control systems, this module enables real-time communication in complex industrial environments. As part of the AC500 ecosystem, the 500CIM05 1MRB150077R1B supports multiple communication protocols, including Ethernet/IP, Profibus DP, and Modbus RTU, making it versatile for integrating with diverse field devices and supervisory control and data acquisition (SCADA) systems.

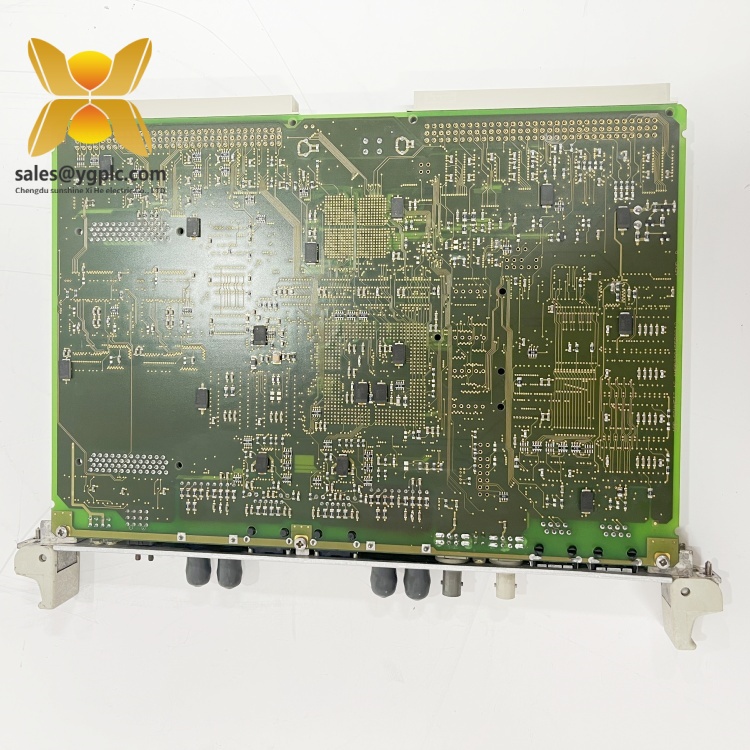

Key functionalities of the ABB 500CIM05 1MRB150077R1B include protocol conversion, data buffering, and fault tolerance. Its dual-port Ethernet interface allows for redundant network configurations, minimizing downtime in mission-critical applications. The module’s compact design (100 mm × 160 mm × 60 mm) and DIN rail mounting ensure easy integration into control panels, while its rugged construction (IP20 rating) protects against dust, moisture, and electromagnetic interference. By enabling real-time monitoring and remote diagnostics, the 500CIM05 1MRB150077R1B enhances system efficiency and reduces maintenance costs across industries such as manufacturing, energy, and water treatment.

In automation architectures, the 500CIM05 1MRB150077R1B acts as a bridge between the AC500 PLC and external devices, ensuring reliable transmission of control commands and process data. Its support for hot-swappable functionality allows for module replacement without powering down the system, improving operational continuity. Whether deployed in standalone machines or large-scale distributed control systems, this module delivers consistent performance, making it an essential component for modern industrial digitization and Industry 4.0 initiatives.

Technical Specifications:ABB 500CIM05 1MRB150077R1B

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 500CIM05 1MRB150077R1B |

| Manufacturer | ABB |

| Product Type | Communication Interface Module |

| Platform | AC500 Series |

| Communication Protocols | Ethernet/IP, Profibus DP, Modbus RTU, CANopen |

| Interface Ports | 2 × Ethernet (10/100 Mbps), 1 × Profibus DP, 1 × RS-485 |

| Power Supply | 24 V DC ±20% (redundant inputs) |

| Physical Dimensions | 100 mm (H) × 160 mm (W) × 60 mm (D) |

| Weight | 0.5 kg |

| Operating Temperature | -25°C to +70°C |

| Mounting | DIN rail (35 mm) |

| Certifications | CE, UL, IEC 61131-2 |

| Data Transfer Rate | Up to 100 Mbps (Ethernet), 12 Mbps (Profibus) |

ABB 500CIM05 1MRB150077R1B

Key Features and Advantages:ABB 500CIM05 1MRB150077R1B

Multi-Protocol Compatibility: The 500CIM05 1MRB150077R1B supports a wide range of industrial communication protocols, eliminating the need for multiple interface modules and simplifying system integration. This flexibility allows it to connect legacy devices and modern smart sensors within a single network.

Redundant Network Design: With dual Ethernet ports, the module enables ring or star network topologies, providing redundancy to prevent communication failures. This feature is critical for maintaining uninterrupted operation in applications where downtime is costly, such as oil refineries or automotive assembly lines.

Hot-Swap Capability: The module’s hot-swappable design allows for replacement while the system is running, reducing maintenance time and minimizing disruptions to production processes. This feature is particularly valuable in 24/7 operational environments.

Compact and Rugged Design: Measuring just 100 mm × 160 mm × 60 mm, the 500CIM05 1MRB150077R1B optimizes space in control panels, making it suitable for small-to-medium-sized automation systems. Its rugged enclosure and conformal coating ensure reliable performance in harsh industrial environments with high vibration or humidity.

Advanced Diagnostics: Built-in LED indicators and diagnostic tools provide real-time feedback on network status, power supply health, and data transmission errors. This proactive monitoring enables quick troubleshooting and reduces mean time to repair (MTTR).

Seamless Integration with AC500 Series: As part of ABB’s AC500 platform, the module integrates seamlessly with AC500 CPU modules (e.g., PM590) and I/O modules, allowing for unified programming and configuration via ABB’s Automation Builder software. This ecosystem compatibility streamlines system setup and reduces training costs.

ABB 500CIM05 1MRB150077R1B

Application Areas:ABB 500CIM05 1MRB150077R1B

The ABB 500CIM05 1MRB150077R1B is widely applied in industries requiring reliable and flexible communication solutions:

- Manufacturing: Connects PLCs with robotic systems, conveyors, and HMIs in automotive, food and beverage, and electronics production lines, enabling real-time process optimization and quality control.

- Energy and Utilities: Facilitates data exchange between power plant control systems and SCADA networks, supporting remote monitoring of generators, transformers, and renewable energy installations.

- Water and Wastewater Treatment: Integrates pumps, valves, and analytical instruments into a unified control network, ensuring efficient management of water distribution and wastewater treatment processes.

- Oil and Gas: Used in offshore platforms and refineries to connect field devices (e.g., flow meters, pressure sensors) with central control systems, enabling safe and efficient production monitoring.

Specific applications include:

- Remote Equipment Monitoring: Transmits real-time data from production machines to cloud-based platforms for predictive maintenance, reducing unplanned downtime.

- Process Automation in Batch Operations: Coordinates multiple machines in batch processes, such as chemical synthesis or pharmaceutical manufacturing, ensuring precise timing and sequence control.

- SCADA System Integration: Acts as a gateway between local PLCs and enterprise-level SCADA systems, providing aggregated data for management reporting and compliance tracking.

ABB 500CIM05 1MRB150077R1B

Related Products:ABB 500CIM05 1MRB150077R1B

- ABB PM590-ETH AC500 CPU Module: A high-performance CPU module that pairs with the 500CIM05 1MRB150077R1B to form a complete PLC system, offering advanced control logic and data processing capabilities.

- ABB 500I/O01 1MRK001010R0001 Digital I/O Module: Expands the input/output capabilities of the AC500 system, complementing the communication module in complex automation setups.

- ABB 500CPS02 Power Supply Module: Provides redundant 24 V DC power to the AC500 system, ensuring stable operation of the 500CIM05 1MRB150077R1B and other modules.

- ABB 500COM03 Communication Module: A complementary module supporting additional protocols like Profinet, enabling hybrid network environments with the 500CIM05 1MRB150077R1B.

- ABB TB521 Terminal Base: Simplifies wiring for field devices, providing a standardized connection point for the 500CIM05 1MRB150077R1B and reducing installation complexity.

- ABB 500DIO04 Digital Output Module: Enables control of actuators and relays, working in tandem with the communication module to execute commands from the PLC.

- ABB 500AI06 Analog Input Module: Acquires continuous process variables (e.g., temperature, pressure) and transmits data via the 500CIM05 1MRB150077R1B for centralized processing.

- ABB Automation Builder Software: Design software for configuring the 500CIM05 1MRB150077R1B and other AC500 components, supporting ladder logic, function block diagrams, and structured text programming.

Installation and Maintenance:ABB 500CIM05 1MRB150077R1B

Installation Preparation:

Before installing the ABB 500CIM05 1MRB150077R1B, ensure the DIN rail is securely mounted and grounded. Verify that the power supply (24 V DC) matches the module’s requirements and that network cables are shielded to minimize interference. Mount the module on the DIN rail using the provided clips, ensuring proper spacing for heat dissipation. Connect the Ethernet and Profibus cables to the respective ports, and use ABB’s Automation Builder software to configure network parameters, such as IP address and baud rate.

Before installing the ABB 500CIM05 1MRB150077R1B, ensure the DIN rail is securely mounted and grounded. Verify that the power supply (24 V DC) matches the module’s requirements and that network cables are shielded to minimize interference. Mount the module on the DIN rail using the provided clips, ensuring proper spacing for heat dissipation. Connect the Ethernet and Profibus cables to the respective ports, and use ABB’s Automation Builder software to configure network parameters, such as IP address and baud rate.

Maintenance Recommendations:

- Routine Inspections: Conduct monthly visual checks to ensure all connections are secure and LED indicators are functioning correctly. Clean the module’s vents with compressed air to prevent dust accumulation that could affect heat dissipation.

- Firmware Updates: Periodically update the module’s firmware via Automation Builder to access new features, protocol enhancements, and security patches. Always back up existing configurations before initiating an update.

- Redundancy Testing: Perform quarterly tests of redundant network paths and power supplies to ensure failover mechanisms work as intended. Document test results for maintenance records.

- Spare Parts Management: Store spare 500CIM05 1MRB150077R1B modules in a static-free environment with controlled temperature (10–30°C) and humidity (20–80%), ensuring quick replacement during unexpected failures.

ABB 500CIM05 1MRB150077R1B

Product Warranty:ABB 500CIM05 1MRB150077R1B

Our company provides a 12-month quality warranty for the ABB 500CIM05 1MRB150077R1B, covering hardware defects under normal operational conditions. In the event of a malfunction, we offer prompt replacement services to minimize downtime. For discontinued or hard-to-find models, our global supply chain network is equipped to source rare industrial control components, ensuring timely support for urgent needs. Our technical team is available 24/7 to assist with installation, troubleshooting, and system optimization, delivering reliable solutions to keep your automation systems running efficiently.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

ABB PM511V16 3BSE011181R1 Analog output module

ABB S-093H 3BHB009885R0004 display

ABB PFSK152 3BSE018877R1 Relay output

ABB SR511 3BSE000863R0001 Optical isolation module

ABB XUD194 3BHE018137R0001 AC800PEC transformer

ABB XUD194 XUD194A 3BHC018137R0001 Digital output module

ABB HS810 3BDH000305R0101 Control system power supply

ABB UNITROL1020 UNS0119A-Z,V1 3BHE030579R0001 Pressure transmitter

ABB AO2040 Main frame

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: