Description

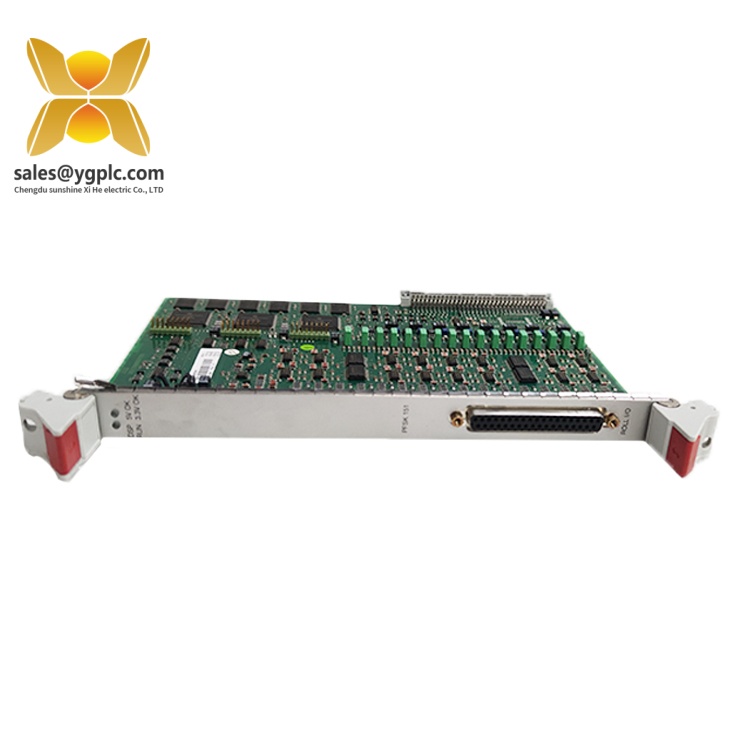

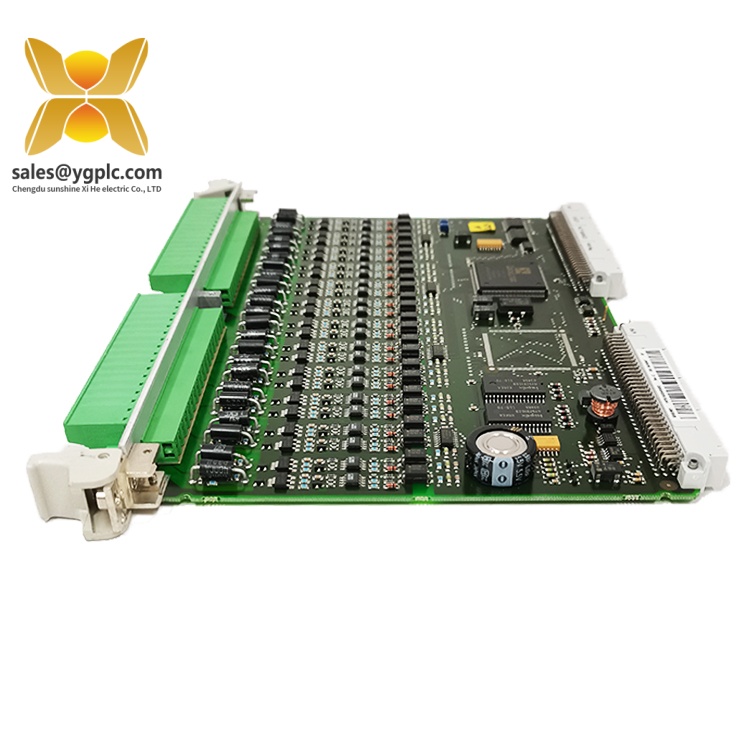

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 500BIM01 1MRB150024R0002 |

| Manufacturer | ABB |

| Product Type | Interface Module |

| Operating Voltage | 24V DC, ±10% |

| Power Consumption | Low – power design, typically ≤5W |

| Communication Protocols | Supports protocols like Modbus RTU, Profibus – DP, and Ethernet/IP |

| Number of Communication Ports | Multiple ports for versatile connectivity |

| Data Transfer Rate | High – speed data transfer, up to 20 Mbps depending on the protocol |

| Physical Dimensions (L x W x H) | [Specific dimensions in mm] |

| Mounting Method | DIN – rail mountable for easy installation |

| Operating Temperature | – 10°C to +50°C |

| Storage Temperature | – 20°C to +70°C |

| Humidity Range | 5% – 95% non – condensing |

| Input/Output Signals | Compatible with digital and analog input/output signals |

500BIM01 1MRB150024R0002

Main Features and Advantages

High – Speed Data Transfer

Multiple Communication Protocol Support

One of the standout features of this module is its compatibility with multiple communication protocols, including Modbus RTU and Profibus – DP. This versatility makes it suitable for use in diverse industrial environments, regardless of the existing communication infrastructure. In a chemical plant that has a mix of legacy and modern equipment, the 500BIM01 1MRB150024R0002 can interface with older devices that use Modbus RTU while also connecting to newer, more advanced systems that operate on Profibus – DP. This seamless integration across different protocols simplifies the overall industrial network architecture and reduces the need for complex and costly protocol converters.

500BIM01 1MRB150024R0002

Robust and Reliable Design

Easy Installation and Maintenance

Application Areas

Manufacturing Industry

In manufacturing plants, the ABB 500BIM01 1MRB150024R0002 is widely used to manage and optimize production processes. It can interface with various production equipment, such as robotic arms, conveyor belts, and automated storage and retrieval systems. In a smartphone manufacturing facility, the module can connect sensors on the robotic arms that assemble the phone components. These sensors can detect the position and orientation of the components, and the data is sent via the 500BIM01 1MRB150024R0002 to the control system. The control system can then adjust the movement of the robotic arms in real – time, ensuring accurate assembly. Additionally, the module can communicate with the conveyor belt system, controlling the speed and flow of products along the production line, maximizing efficiency and minimizing bottlenecks.

500BIM01 1MRB150024R0002

Energy Sector

Food and Beverage Industry

Water and Wastewater Treatment

Water treatment plants rely on the ABB 500BIM01 1MRB150024R0002 to control and monitor the treatment process. The module can connect sensors that measure parameters such as water quality (pH, turbidity, chlorine levels), flow rate, and pressure. In a water purification plant, sensors can detect the presence of impurities in the incoming water. The data is transmitted via the 500BIM01 1MRB150024R0002 to the control system, which can then adjust the dosing of chemicals, the operation of filters, and the flow rate of water through the treatment system. In wastewater treatment plants, the module can manage the treatment process by controlling the activation of treatment equipment, such as aerators and sludge pumps, ensuring that the wastewater is treated effectively before being discharged.

500BIM01 1MRB150024R0002

Related Products

- ABB 500BIM02 1MRB150025R0002: An upgraded version of the 500BIM01 1MRB150024R0002, offering enhanced data processing capabilities and additional communication ports. It is suitable for more complex industrial applications where a higher volume of data needs to be transferred and processed.

- ABB 500CIM01 1MRB150026R0002: A different type of interface module in the ABB product line, with a focus on providing more specialized communication interfaces, such as for specific industrial sensors or actuators. It may be used in applications where the 500BIM01 1MRB150024R0002‘s standard interfaces are not sufficient.

- ABB AC500 PLC Series: These programmable logic controllers work in tandem with the 500BIM01 1MRB150024R0002. The PLCs can receive data from the interface module and execute control algorithms based on that data. For example, the AC500 – eco PLC can be used in small – to – medium – sized industrial applications, and the 500BIM01 1MRB150024R0002 can provide it with real – time data from field devices.

- ABB Communication Cables: Specific cables designed to be used with the 500BIM01 1MRB150024R0002 to ensure reliable and high – speed data transfer. Different cables are available for different communication protocols, such as Ethernet cables for high – speed data transfer over Ethernet/IP and shielded cables for use in environments with high electromagnetic interference when using protocols like Profibus – DP.

- ABB Power Supply Modules: These modules are essential for providing a stable power source to the 500BIM01 1MRB150024R0002 and other components in the industrial control system. They come in various voltage ratings and power capacities to meet the specific requirements of different applications.

Installation and Maintenance

Installation Preparations

Maintenance Recommendations

Regularly inspect the 500BIM01 1MRB150024R0002 for any signs of physical damage. Check for cracks in the module’s enclosure, loose screws, or any visible signs of wear and tear. Clean the module periodically to remove dust and debris, as these can accumulate over time and affect the module’s performance, especially in environments with high levels of dust. Monitor the operating temperature of the module using appropriate temperature – monitoring devices. The module should operate within the specified temperature range of – 10°C to +50°C. If the temperature exceeds this range, it can cause the module to malfunction. Check the communication status of the module with other devices in the network regularly. Use diagnostic tools provided by ABB or third – party software to detect any communication errors, such as packet loss or slow data transfer rates. If any faults are detected, refer to the troubleshooting guide in the product manual. In case of persistent problems, contact ABB’s technical support or our company’s experienced technicians, who are well – versed in handling ABB industrial control products, for assistance.

500BIM01 1MRB150024R0002

Product Assurance

Our company provides a one – year quality warranty for the ABB 500BIM01 1MRB150024R0002, covering hardware failures due to non – human factors. During this period, if the product shows any performance anomalies or functional failures, we will promptly provide replacement services. For discontinued models or in case of urgent needs, our extensive global supply chain network enables us to quickly respond to customers’ requests for scarce spare parts. With 17 years of experience in the industrial control industry, we are committed to ensuring that the ABB 500BIM01 1MRB150024R0002 and all the products we sell contribute to the stable and continuous operation of industrial systems. Our team of experts is always available to provide technical support, whether it’s for installation guidance, troubleshooting, or general product – related inquiries. We strive to offer the best possible service to our customers, ensuring their satisfaction with every purchase.E-mail :sales@ygplc.com.

ABB PM803F 3BDH000530R1 monitor

ABB PFEA113-20 3BSE028144R0020 rack

ABB AO2000 LS25 Remote module

ABB SCYC51020 58052582/G Main processor

ABB PP825A 3BSE042240R3 Pulse input

ABB PPC905AE101 3BHE014070R0101 Digital quantity

ABB DSPU131 3BSE000355R1 Connection base plate

ABB 500CPU03 1HDF700003R5122 redundancy

ABB 500TRM02 1MRB150011R1 Network communication

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: