Description

Product Overview

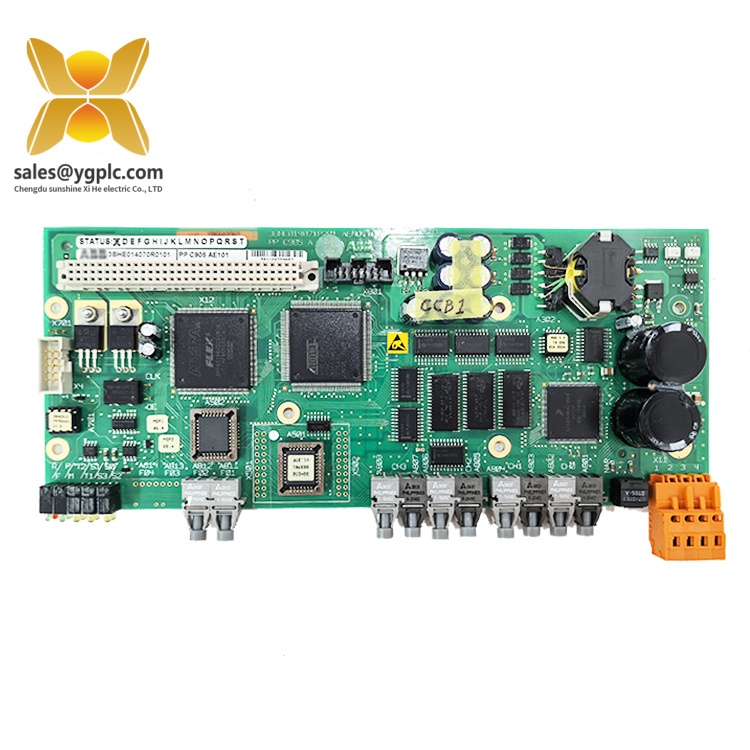

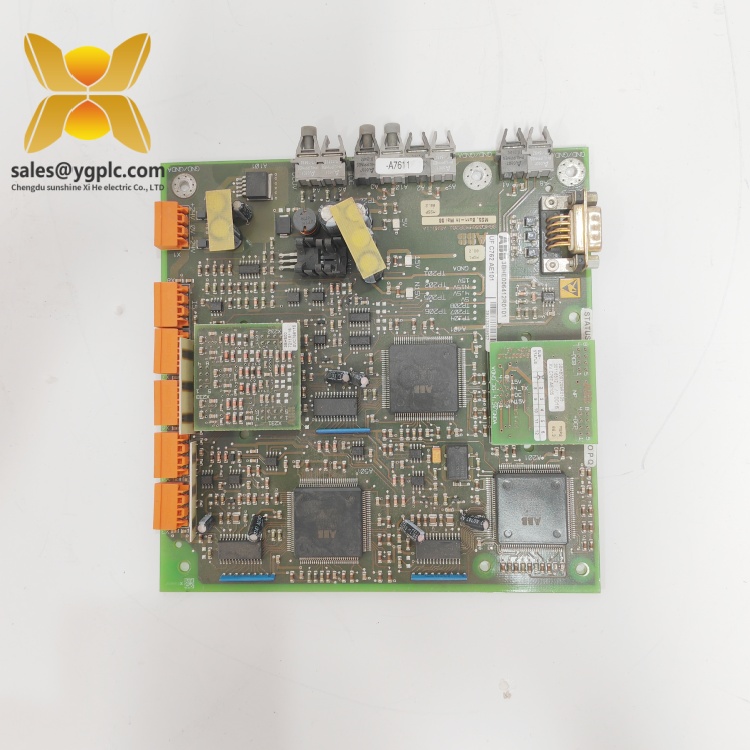

The ABB 3BHE006412R0101 UFC762AE101 is a high – performance motor control module designed for industrial variable speed drives, engineered by ABB—a global leader in power and automation technologies. As a critical component of ABB’s advanced drive systems, this module is part of the ACS800 series, renowned for its reliability and efficiency in managing motor operations across diverse industrial applications.

The 3BHE006412R0101 UFC762AE101 serves as the control heart of variable frequency drives, enabling precise regulation of motor speed, torque, and direction. It processes input signals from sensors and control systems, translating them into optimized output commands for motors, ensuring smooth operation and energy efficiency. With its robust design and advanced digital signal processing capabilities, this module can handle complex motor control algorithms, making it suitable for both simple and sophisticated drive applications.Whatsapp:+86 18859254943.

In industrial automation, the ABB 3BHE006412R0101 UFC762AE101 plays a pivotal role in integrating motor drives into larger control systems. It supports seamless communication with PLCs, DCS networks, and human – machine interfaces (HMIs), enabling real – time monitoring and adjustment of motor performance. By minimizing energy consumption, reducing mechanical stress on motors, and enhancing system reliability, this module delivers significant operational and cost benefits, positioning it as an essential component for industries where precise motor control is non – negotiable.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3BHE006412R0101 UFC762AE101 |

| Manufacturer | ABB |

| Product Type | Motor Control Module (Variable Frequency Drive Controller) |

| Input Voltage Range | 24 V DC (control power), 380–480 V AC (main power, depending on drive configuration) |

| Output Frequency | 0–500 Hz (adjustable via software) |

| Control Techniques | Vector control, direct torque control (DTC), sensorless control |

| Communication Protocols | Profibus DP, Modbus TCP, Ethernet/IP, DeviceNet |

| Power Rating | Suitable for motors up to 500 kW (dependent on drive model integration) |

| Operating Temperature | -10°C to +50°C (with derating at higher temperatures) |

| Storage Temperature | -40°C to +70°C |

| Humidity Resistance | 5%–95% non – condensing |

| Physical Dimensions | 200 mm (W) × 300 mm (H) × 150 mm (D) |

| Mounting Method | Rack – mountable (for drive cabinets) |

| Input/Output Channels | 8 digital inputs, 4 analog inputs, 6 relay outputs, 2 analog outputs |

| Diagnostic Features | Real – time fault monitoring, thermal protection, overload detection |

| Compliance Standards | CE, UL, cUL, IEC 61800 – 3 |

3BHE006412R0101 UFC762AE101

Main Features and Advantages

Advanced Control Algorithms

The ABB 3BHE006412R0101 UFC762AE101 incorporates ABB’s proprietary direct torque control (DTC) technology, delivering precise motor control with fast response times. This technology eliminates the need for speed sensors, reducing system complexity while maintaining high accuracy in torque and speed regulation. Whether applied to pumps, fans, or high – performance motors in manufacturing, this module ensures smooth acceleration, deceleration, and load handling, minimizing mechanical stress and extending motor lifespan.

Flexible Communication Capabilities

With support for multiple industrial communication protocols, the module integrates seamlessly into any automation network. It enables real – time data exchange with higher – level systems, allowing operators to monitor motor performance, adjust parameters remotely, and troubleshoot issues proactively. For example, in a smart factory setup, it can communicate with a PLC to optimize motor speed based on real – time production demands, enhancing overall process efficiency.

Rugged Industrial Design

Engineered for harsh environments, the 3BHE006412R0101 UFC762AE101 features a robust enclosure that resists dust, moisture, and electromagnetic interference. Its wide operating temperature range and humidity tolerance make it suitable for use in challenging settings such as offshore platforms, steel mills, and chemical plants. The module’s thermal management design ensures stable operation even under continuous high – load conditions, reducing the risk of overheating and unplanned downtime.

Easy Integration and Maintenance

The module’s plug – and – play design simplifies installation within drive cabinets, with standardized interfaces for power, signals, and communication. ABB’s intuitive commissioning software allows engineers to configure parameters quickly, while built – in diagnostic tools provide real – time feedback on module health. In the event of a fault, clear fault codes and status indicators enable rapid troubleshooting, minimizing maintenance time and costs.

Energy Efficiency Optimization

By precisely controlling motor speed and torque, the ABB 3BHE006412R0101 UFC762AE101 helps reduce energy consumption by up to 30% compared to fixed – speed systems. This not only lowers operational costs but also contributes to sustainability goals, making it an ideal choice for industries aiming to enhance their energy efficiency.Whatsapp:+86 18859254943.

Application Areas

Manufacturing Industry

In manufacturing plants, the 3BHE006412R0101 UFC762AE101 is used to control conveyor belts, pumps, and robotic arm motors. For instance, in an automotive assembly line, it ensures smooth speed adjustments for conveyor systems, synchronizing material flow with production rates. In textile mills, it enables precise control of spinning and weaving machines, improving product quality by maintaining consistent motor speeds.

Energy and Power Generation

In power plants, this module regulates motors in cooling systems, steam turbines, and generator exciters. It optimizes the performance of pumps and fans in thermal power plants, adjusting their speed based on load requirements to reduce energy waste. In renewable energy sectors, such as wind farms, it controls the pitch and yaw motors of wind turbines, maximizing energy capture and ensuring safe operation in varying wind conditions.

Water and Wastewater Treatment

For water management systems, the 3BHE006412R0101 UFC762AE101 controls pumps and blowers, adjusting their speed to match water demand or treatment process requirements. In wastewater plants, it optimizes the operation of aeration systems, ensuring efficient oxygen transfer while reducing energy consumption. Its ability to handle variable loads makes it suitable for both small – scale pumping stations and large – scale treatment facilities.Whatsapp:+86 18859254943.

3BHE006412R0101 UFC762AE101

Oil and Gas

In the oil and gas industry, the module is used in pumps, compressors, and offshore drilling equipment. It ensures reliable motor control in harsh offshore environments, withstanding salt corrosion and extreme temperatures. For example, it regulates the speed of subsea pumps, maintaining stable fluid flow while adapting to changing well pressures, critical for safe and efficient extraction operations.

Mining and Minerals

Mining operations rely on the 3BHE006412R0101 UFC762AE101 to control conveyor belts, crushers, and ventilation systems. It handles the high – torque demands of mining equipment, providing smooth start – stop operations to reduce mechanical wear. In underground mines, its rugged design ensures reliable performance in dusty and humid conditions, essential for maintaining continuous production.

Related Products

- ABB 3BHE006413R0101 UFC762AE201: An upgraded version with enhanced processing power and additional communication ports, suitable for large – scale industrial drives requiring higher computational capabilities.

- ABB ACS880 – 01 – 02A3 – 3: A complete variable speed drive system that integrates the 3BHE006412R0101 UFC762AE101 module, designed for low – voltage applications up to 400 kW.

- ABB PP836A: A communication interface module that works with the 3BHE006412R0101 UFC762AE101 to enable Profinet or Ethernet/IP connectivity, expanding network integration options.

- ABB UNITROL 5000: A generator excitation system that pairs with the module for precise control in power generation applications, ensuring stable voltage and frequency regulation.

- ABB S800 I/O Modules: Complementary input/output modules that expand the signal processing capabilities of the 3BHE006412R0101 UFC762AE101, supporting additional sensors and actuators.

- ABB PS501A: A redundant power supply module designed to provide stable 24 V DC power to the 3BHE006412R0101 UFC762AE101, enhancing system reliability in critical applications.

- ABB PM866A: A processor module that integrates with the motor control module in complex automation systems, enabling advanced algorithm processing and system coordination.

Installation and Maintenance

Installation Preparations:

Before installing the ABB 3BHE006412R0101 UFC762AE101, ensure all power sources to the drive system are disconnected and the cabinet is properly grounded. Verify the module’s compatibility with the drive model and system voltage requirements. Mount the module securely on the drive cabinet’s rack, ensuring proper alignment and tight fastening to prevent vibrations. Connect the control power cable (24 V DC) and main power cables according to the wiring diagram, ensuring all connections are shielded to minimize electromagnetic interference. Finally, configure the communication parameters using ABB’s DriveWindow software to match the network protocol and address settings.

Before installing the ABB 3BHE006412R0101 UFC762AE101, ensure all power sources to the drive system are disconnected and the cabinet is properly grounded. Verify the module’s compatibility with the drive model and system voltage requirements. Mount the module securely on the drive cabinet’s rack, ensuring proper alignment and tight fastening to prevent vibrations. Connect the control power cable (24 V DC) and main power cables according to the wiring diagram, ensuring all connections are shielded to minimize electromagnetic interference. Finally, configure the communication parameters using ABB’s DriveWindow software to match the network protocol and address settings.

3BHE006412R0101 UFC762AE101

Maintenance Recommendations:

Regularly inspect the 3BHE006412R0101 UFC762AE101 for loose connections, dust accumulation, or signs of thermal stress. Clean the module’s exterior with a dry, static – free cloth to maintain optimal heat dissipation. Monitor the drive system’s diagnostic interface for fault codes, which may indicate issues such as overvoltage, overcurrent, or communication errors. Periodically update the module’s firmware using ABB’s official software to access the latest features and security patches. In case of persistent faults, replace the module with a verified spare part and consult ABB’s technical documentation for troubleshooting guidance.

Regularly inspect the 3BHE006412R0101 UFC762AE101 for loose connections, dust accumulation, or signs of thermal stress. Clean the module’s exterior with a dry, static – free cloth to maintain optimal heat dissipation. Monitor the drive system’s diagnostic interface for fault codes, which may indicate issues such as overvoltage, overcurrent, or communication errors. Periodically update the module’s firmware using ABB’s official software to access the latest features and security patches. In case of persistent faults, replace the module with a verified spare part and consult ABB’s technical documentation for troubleshooting guidance.

Product Assurance

Our company provides a one – year quality warranty for the ABB 3BHE006412R0101 UFC762AE101, covering hardware failures due to non – human factors. During the warranty period, we will promptly replace any module that exhibits performance anomalies or functional failures, ensuring minimal disruption to your operations. For discontinued models or urgent requirements, our global supply chain network allows us to source and deliver scarce spare parts quickly, leveraging our 17 years of expertise in industrial control distribution. We are committed to supporting your system’s reliability, offering technical assistance and product assurance that meets the rigorous demands of industrial automation. Trust us to be your partner in maintaining efficient, safe, and sustainable operations with the 3BHE006412R0101 UFC762AE101 and our comprehensive range of industrial control solutions.E-mail :sales@ygplc.com.

ABB 500B0M01 1MRB150023R0002 PLC module card

ABB 500MBA02 1MRB150003R000B Digital output card

ABB 500MBA02 1MRB150003R0003 1MRB200053M Dual digital output module

ABB 500PB101 1MRB178009R0001 1MRB200064/C convertor

ABB SC520 3BSE003816R1 Control panel

ABB CS513 3BSE000435R1 Double output

ABB 216DB61 HESG324063R100/J Control processor

ABB 216EA62 1MRB150083R1/F 1MRB178066R1/F Switch quantity input card

ABB UFC718AE101 HIEE300936R0101 Enhanced intelligent communication module

ABB 500B0M01 1MRB150023R0002 PLC module card

ABB 500MBA02 1MRB150003R000B Digital output card

ABB 500MBA02 1MRB150003R0003 1MRB200053M Dual digital output module

ABB 500PB101 1MRB178009R0001 1MRB200064/C convertor

ABB SC520 3BSE003816R1 Control panel

ABB CS513 3BSE000435R1 Double output

ABB 216DB61 HESG324063R100/J Control processor

ABB 216EA62 1MRB150083R1/F 1MRB178066R1/F Switch quantity input card

ABB UFC718AE101 HIEE300936R0101 Enhanced intelligent communication module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: