Description

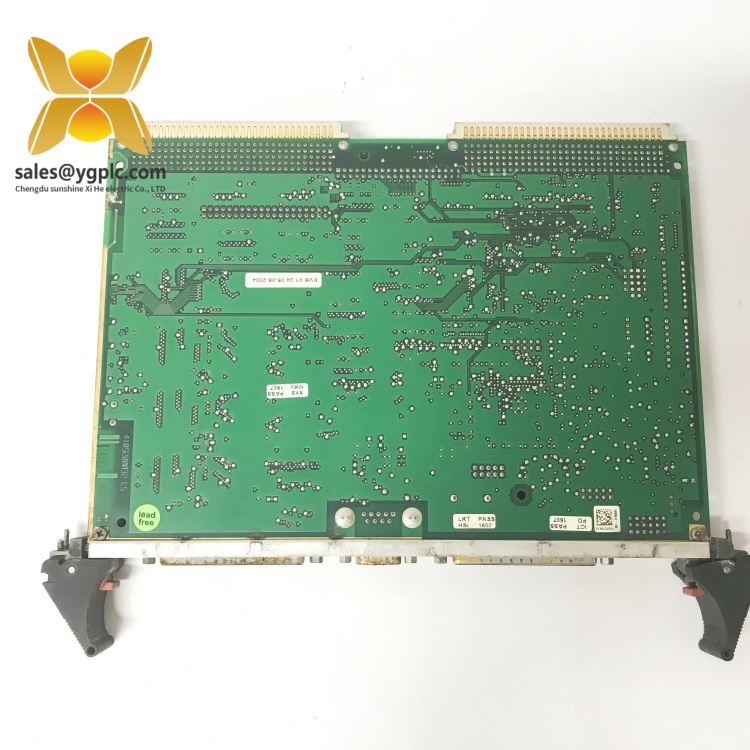

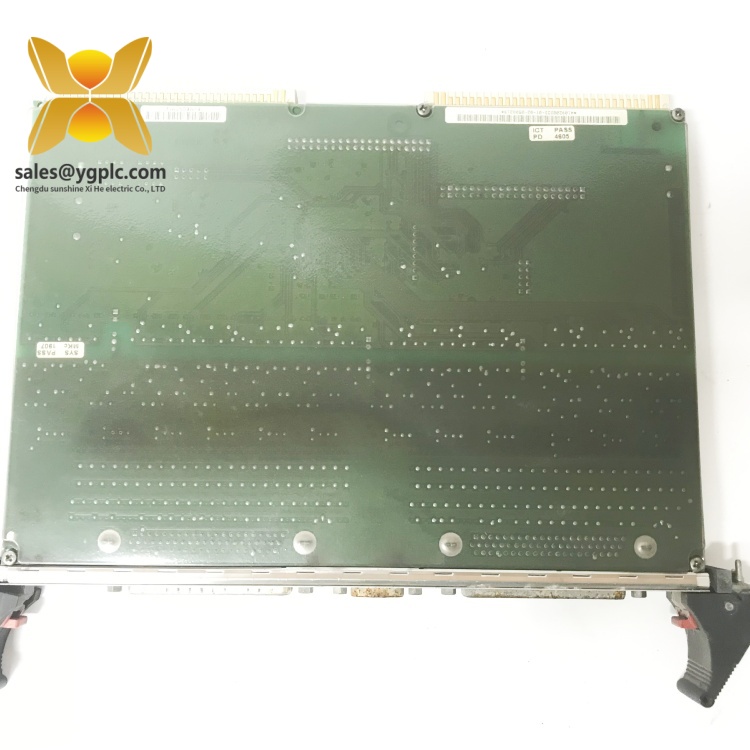

Product Overview:GE EVMECNTM13

The GE EVMECNTM13 motor control module is a high-performance industrial automation component designed to deliver precise and reliable control of electric motors in complex industrial systems. As part of GE’s Evolution Series, this module serves as a central hub for motor management, integrating seamlessly with GE’s PLCs and distributed control systems (DCS) to optimize motor performance, energy efficiency, and system safety.

Engineered for versatility, the EVMECNTM13 supports a wide range of motor types, including induction, synchronous, and DC motors, with power ratings up to 500 HP. Its core functions include start/stop control, speed regulation, overload protection, and real-time diagnostics, all managed through a user-friendly interface. The module’s dual-core processor ensures rapid response to control commands and real-time data processing, while its redundant power supply inputs (24V DC/120V AC) enhance system reliability in mission-critical applications.

In automation systems, the EVMECNTM13 plays a pivotal role in reducing downtime and operational costs. By continuously monitoring motor parameters such as current, voltage, and temperature, it enables predictive maintenance and early fault detection, minimizing unplanned outages. Its compatibility with EtherNet/IP, Modbus TCP, and Profibus DP communication protocols ensures seamless integration with both GE and third-party systems, making it an ideal solution for smart factories, power plants, and process industries seeking scalable and interoperable motor control solutions.

Technical Specifications:GE EVMECNTM13

| Parameter Name | Parameter Value |

|---|---|

| Product Model | EVMECNTM13 |

| Manufacturer | GE |

| Product Type | Motor Control Module |

| Input Voltage | 24V DC / 120V AC (dual redundant) |

| Power Rating | Up to 500 HP |

| Communication Protocols | EtherNet/IP, Modbus TCP, Profibus DP |

| Physical Dimensions | 10.2″ x 8.5″ x 4.3″ (259mm x 216mm x 109mm) |

| Weight | 5.8 lbs (2.63 kg) |

| Operating Temperature | -40°C to +60°C |

| Humidity | 5–95% non-condensing |

| Mounting Type | Panel-mounted (DIN rail compatible) |

| Certifications | UL, CE, CSA |

EVMECNTM13

Key Features and Advantages:GE EVMECNTM13

Advanced Motor Management: The EVMECNTM13 offers variable frequency control and soft-start capabilities, reducing mechanical stress on motors and connected equipment. Its built-in PID controller enables precise speed regulation, making it suitable for applications requiring tight process control, such as conveyor systems or pump stations.

Robust Protection Features: The module includes overcurrent, overvoltage, and thermal overload protection, safeguarding motors from damage and ensuring compliance with industrial safety standards. Its lockout/tagout (LOTO) functionality enhances worker safety during maintenance.

Real-Time Diagnostics: Integrated LED indicators and a LCD display provide instant visibility into motor status, fault codes, and performance metrics. The module’s historical data logging feature allows operators to analyze trends and optimize maintenance schedules.

Scalable and Interoperable: With support for multiple communication protocols, the EVMECNTM13 integrates easily with GE’s iFIX SCADA and Proficy HMI/SCADA systems, as well as third-party platforms. Its plug-and-play design minimizes installation time, while firmware updates via Ethernet ensure compatibility with evolving automation technologies.

Energy Efficiency: The module’s regenerative braking and adaptive voltage control features reduce energy consumption by up to 30%, making it an environmentally friendly choice for industries aiming to lower carbon footprints.

Application Areas:GE EVMECNTM13

The GE EVMECNTM13 motor control module is ideally suited for industries where reliable motor performance is critical:

- Manufacturing: Powers assembly lines, robotics, and CNC machines, ensuring smooth operation and precise positioning. In automotive factories, the module controls conveyor belts and robotic welders, optimizing production speed and quality.

- Power Generation: Manages pumps, fans, and turbines in power plants, enabling efficient energy production. Its redundancy features are essential for maintaining continuous operation in steam turbine systems.

- Oil & Gas: Used in refineries and offshore platforms to control compressors, mixers, and submersible pumps. The module’s rugged design withstands harsh environments, including high humidity and vibration.

- Water/Wastewater Treatment: Controls pumps and blowers in water treatment plants, ensuring consistent water flow and quality. Its PID control capabilities are critical for maintaining optimal chemical dosing rates.

- Mining: Drives conveyor belts, crushers, and ventilation systems in mining operations, enhancing safety and productivity. The module’s overload protection prevents damage from sudden mechanical stress.

EVMECNTM13

Related Products:GE EVMECNTM13 Motor Control Module

- GE EVMEDRV12 Drive Module: AMatching frequency conversion driver designed for use with the EVMECNTM13, providing variable speed control for induction motors.

- GE EVMEMON10 Monitoring Module: Enhances the EVMECNTM13 with advanced condition monitoring, including vibration analysis and thermal imaging.

- GE IC695CPU310 PLC Controller: Integrates with the EVMECNTM13 for centralized control of motor networks in large-scale automation systems.

- GE IS200TBCBH1B Terminal Block: A hardware accessory that simplifies wiring and connectivity for the EVMECNTM13 in control panels.

- GE 90-30 Series I/O Modules: Expand the input/output capabilities of the EVMECNTM13, enabling integration with sensors and actuators.

- GE EVMECNTM15 Advanced Control Module: An upgraded version with built-in cybersecurity features, suitable for industrial IoT (IIoT) applications.

- GE Proficy Machine Edition Software: A programming and configuration tool for the EVMECNTM13, supporting ladder logic and function block diagrams.

Installation and Maintenance:GE EVMECNTM13

Installation Preparation:

Before installing the EVMECNTM13, verify the power supply matches the module’s requirements (24V DC or 120V AC). Ensure the mounting panel is grounded and free of debris, then secure the module using the provided DIN rail clips or screws. Connect motor leads to the terminal blocks, ensuring proper torque specifications, and link the module to the control network via Ethernet or serial cables. Finally, configure the module’s parameters using GE’s Proficy software, setting up motor type, overload limits, and communication protocols.

Before installing the EVMECNTM13, verify the power supply matches the module’s requirements (24V DC or 120V AC). Ensure the mounting panel is grounded and free of debris, then secure the module using the provided DIN rail clips or screws. Connect motor leads to the terminal blocks, ensuring proper torque specifications, and link the module to the control network via Ethernet or serial cables. Finally, configure the module’s parameters using GE’s Proficy software, setting up motor type, overload limits, and communication protocols.

Maintenance Recommendations:

- Routine Inspections: Monthly checks should include verifying power supply voltages, inspecting for loose connections, and cleaning dust from the module’s vents to prevent overheating.

- Firmware Updates: Periodically update the module’s firmware to address security patches and enhance functionality, following GE’s official release notes.

- Component Testing: Annually test the module’s protective functions, such as overload trips and emergency stop responses, using simulated fault conditions.

- Environmental Checks: In harsh environments, increase inspection frequency to monitor for signs of corrosion or mechanical wear, particularly in mounting brackets and terminal blocks.

EVMECNTM13

Product Warranty:GE EVMECNTM13

We provide a 12-month quality warranty for the GE EVMECNTM13 motor control module, covering non-human-induced hardware defects. During the warranty period, we will replace any faulty module at no cost. For discontinued models or urgent needs, our global supply chain ensures rapid delivery of rare components, minimizing downtime for critical systems.

With 17 years of expertise in industrial control distribution, we offer competitive pricing, expedited shipping, and 24/7 technical support. Contact us to leverage the EVMECNTM13 for reliable, energy-efficient motor control in your automation system.

Note: All trademarks belong to their respective owners. This document is for informational purposes and does not substitute official technical documentation. Always refer to GE’s manuals for detailed installation and safety guidelines.

GE IS220PDIAH1A driver

GE CK11CE300 servo

GE IS200JPDMG1ACC S1AT005 programmable

GE IS200TSVCH1AED Logic controller

GE IC695CPE400-ABAB Safety system

GE SR469 469-P5-HI-A20-E Connecting module

GE IS220PDIAH1A driver

GE IS420UCSBH3A DO module

GE IS220PDIAH1A driver

GE CK11CE300 servo

GE IS200JPDMG1ACC S1AT005 programmable

GE IS200TSVCH1AED Logic controller

GE IC695CPE400-ABAB Safety system

GE SR469 469-P5-HI-A20-E Connecting module

GE IS220PDIAH1A driver

GE IS420UCSBH3A DO module

中文版

中文版

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: