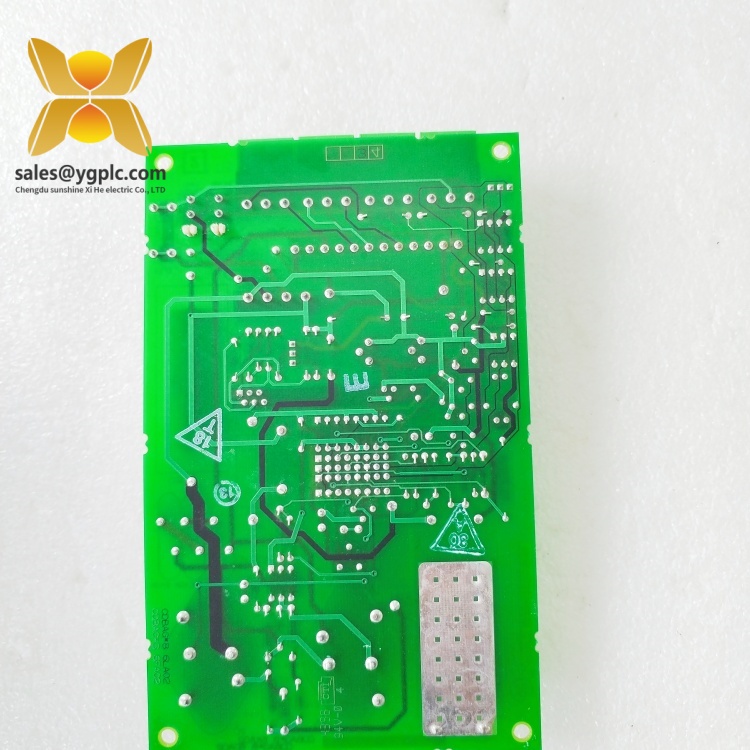

GE DS200PCCAG6A Mark VIe Processor Module

Product Overview

The GE DS200PCCAG6A is a high-performance Processor Module designed as the central control unit for GE’s Mark VIe distributed control system (DCS). Engineered to deliver real-time processing and deterministic control for critical industrial applications, this module serves as the brain of power generation, oil & gas, and manufacturing systems, managing complex algorithms and communication protocols with precision. As part of the DS200 Series, the DS200PCCAG6A integrates seamlessly with GE’s Proficy software suite, enabling advanced automation, diagnostics, and predictive maintenance across diverse industrial environments.

Featuring a redundant architecture and hot-swappable design, the GE DS200PCCAG6A ensures continuous operation even during module replacement or firmware updates, minimizing downtime in mission-critical processes. Its 32-bit RISC processor executes control logic at speeds up to 100 milliseconds, supporting high-speed I/O scanning and closed-loop control for applications such as turbine governors, boiler control, and compressor management. The module’s extensive communication capabilities include Ethernet, Serial, and GE’s proprietary MarkNet protocol, facilitating integration with legacy systems and modern industrial networks.

In automation ecosystems, the DS200PCCAG6A orchestrates data flow between field devices, I/O modules, and human-machine interfaces (HMIs), ensuring cohesive system operation. Its fault-tolerant design includes dual-channel communication paths and redundant power supplies, meeting stringent reliability requirements for industries where system failures can result in safety hazards or significant financial losses. By combining robust hardware with intelligent software, this module optimizes process efficiency, reduces maintenance costs, and extends the lifecycle of industrial control systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200PCCAG6A |

| Manufacturer | GE |

| Product Type | Processor Module |

| Platform | Mark VIe |

| Processor | 32-bit RISC, 100 MHz |

| Memory | 128 MB RAM, 128 MB Flash |

| Communication Interfaces | 2 Ethernet ports (10/100 Mbps), 2 Serial ports (RS-232/485), MarkNet protocol |

| I/O Scanning Rate | Up to 100 ms |

| Redundancy | Hot-swappable, redundant capable |

| Power Supply | 24 V DC ±10%, redundant inputs |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.6 kg |

| Operating Temperature | -40°C to +85°C |

| Certifications | IEC 61131-2, UL, CSA, CE |

| Mounting | Rack-mounted in Mark VIe enclosure |

Key Features and Advantages

High-Speed Processing: The DS200PCCAG6A’s 100 MHz RISC processor delivers rapid execution of control algorithms, enabling precise regulation of critical processes such as turbine speed control and boiler combustion management. This speed ensures minimal latency in responding to process changes, enhancing system stability.

Redundant Architecture: Designed for fail-safe operation, the module supports redundant configurations, where a standby processor seamlessly takes over in the event of a primary processor failure. This redundancy eliminates single points of failure, ensuring continuous operation in safety-critical applications.

Hot-Swappable Design: The ability to replace the DS200PCCAG6A without shutting down the system reduces maintenance downtime and allows for scheduled upgrades during normal operations, minimizing disruption to production.

Comprehensive Communication: With multiple Ethernet and serial ports, the module supports diverse communication protocols, including Modbus, Profibus, and OPC, facilitating integration with third-party devices and legacy systems. This flexibility simplifies system expansion and modernization.

Advanced Diagnostics: Built-in self-test capabilities continuously monitor processor health, memory usage, and communication integrity. Real-time diagnostic data is available via the Mark VIe operator interface, enabling proactive maintenance and reducing mean time to repair (MTTR).

Rugged Industrial Construction: Engineered to withstand harsh environments, the module resists vibration, shock, and extreme temperatures, ensuring reliable performance in demanding industrial settings such as offshore platforms, refineries, and power plants.

Application Areas

The GE DS200PCCAG6A is critical for applications requiring high-reliability control and automation:

- Power Generation: Manages steam and gas turbines, hydroelectric generators, and boiler control systems, ensuring efficient power production and grid stability.

- Oil & Gas: Controls pipeline compressors, refining processes, and offshore platform systems, maintaining safe and efficient operations in high-risk environments.

- Manufacturing: Orchestrates production lines, robotic systems, and material handling equipment, optimizing throughput and product quality in automotive, chemical, and food processing industries.

- Water/Wastewater: Automates pumping stations, treatment processes, and distribution networks, ensuring reliable water supply and environmental compliance.

Specific applications include:

- Turbine Control: Executes governor algorithms to regulate turbine speed and load, maintaining synchronization with the electrical grid and preventing overspeed conditions.

- Boiler Management: Monitors and controls combustion processes, steam pressure, and temperature, optimizing energy efficiency and reducing emissions.

- Process Automation: Coordinates complex sequences in chemical plants, such as reactor temperature control and batch processing, ensuring precise execution and product consistency.

Related Products

- DS200TCTGG1A (Turbine Control Module): Works in tandem with the DS200PCCAG6A to provide specialized turbine control algorithms and I/O interfaces for power generation applications.

- DS200AADA (Digital Input Module): Provides discrete input signals to the DS200PCCAG6A, enabling monitoring of switches, sensors, and status indicators in industrial processes.

- DS200AASA (Analog Output Module): Converts digital control signals from the DS200PCCAG6A into analog outputs for regulating valves, actuators, and other continuous-control devices.

- DS200COMM (Communication Module): Extends the DS200PCCAG6A’s connectivity options, supporting additional Ethernet or serial protocols for integration with SCADA systems or enterprise networks.

- DS200PWR (Power Supply Module): Supplies redundant power to the Mark VIe rack, ensuring uninterrupted operation of the DS200PCCAG6A and other modules during power fluctuations.

- DS200TBCH (Terminal Block Module): Simplifies field wiring for I/O modules connected to the DS200PCCAG6A, providing a centralized and organized connection point for field devices.

- DS200ALG (Algorithm Module): Enhances the DS200PCCAG6A’s processing capabilities by executing specialized control algorithms, such as PID loops and advanced math functions, for complex process control.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE DS200PCCAG6A, ensure the Mark VIe rack is properly grounded and powered down. Verify that the rack’s power supplies are functioning correctly and configured for redundant operation. Use GE’s Proficy software to configure the processor’s communication settings, I/O addresses, and control logic. Carefully insert the module into the designated slot, ensuring proper alignment and engagement of the locking mechanisms. Reconnect all communication cables and power connections, following GE’s recommended torque specifications to prevent loose connections.

Before installing the GE DS200PCCAG6A, ensure the Mark VIe rack is properly grounded and powered down. Verify that the rack’s power supplies are functioning correctly and configured for redundant operation. Use GE’s Proficy software to configure the processor’s communication settings, I/O addresses, and control logic. Carefully insert the module into the designated slot, ensuring proper alignment and engagement of the locking mechanisms. Reconnect all communication cables and power connections, following GE’s recommended torque specifications to prevent loose connections.

Maintenance Suggestions:

- Regular Inspections: Conduct monthly visual inspections to check for loose connections, overheating, or physical damage to the module. Monitor LED indicators for status updates and fault alerts, addressing any anomalies immediately.

- Firmware Management: Periodically update the DS200PCCAG6A’s firmware using Proficy software to incorporate bug fixes, performance improvements, and new features. Follow GE’s validation procedures to ensure seamless integration with existing system configurations.

- Redundancy Testing: Annually test the redundancy functionality by simulating a processor failure and verifying that the standby module assumes control without disrupting operations. Document test results for compliance audits.

- Spare Parts Storage: Store spare DS200PCCAG6A modules in a static-free environment with controlled temperature and humidity. Rotate inventory periodically to ensure component viability and availability for emergency replacements.

Product Guarantee

Our company provides a 12-month quality warranty for the GE DS200PCCAG6A, covering hardware defects under normal operating conditions. In the event of unexpected failures, we offer prompt replacement services to minimize downtime. For legacy or discontinued models like the DS200PCCAG6A, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, delivering tailored solutions to maintain your Mark VIe system’s reliability and performance.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE DS200QTBAG1ABB Gas turbine card

GE DS200QTBAG1ACB FIM card

GE DS200QTBAG1ADC Communication input interface component

GE DS200RTBAG4A Communication output interface component

GE DS200RTBAG5A Interface component

GE DS200SDCCG1AEC DCS card module

GE DS200SDCCG1AHD Data acquisition module

GE DS200SDCCG4AFD probe

GE DS200SDCCG4AGD regulator

GE DS200SDCCG5A I/O board

GE DS200SDCCGIAGD Power strip

GE DS200SHVG1BGD Power source

GE DS200SHVIG1BHD base

中文版

中文版