GE DS200RTBAG5A Speedtronic Mark VIe Relay Output Module

Product Overview

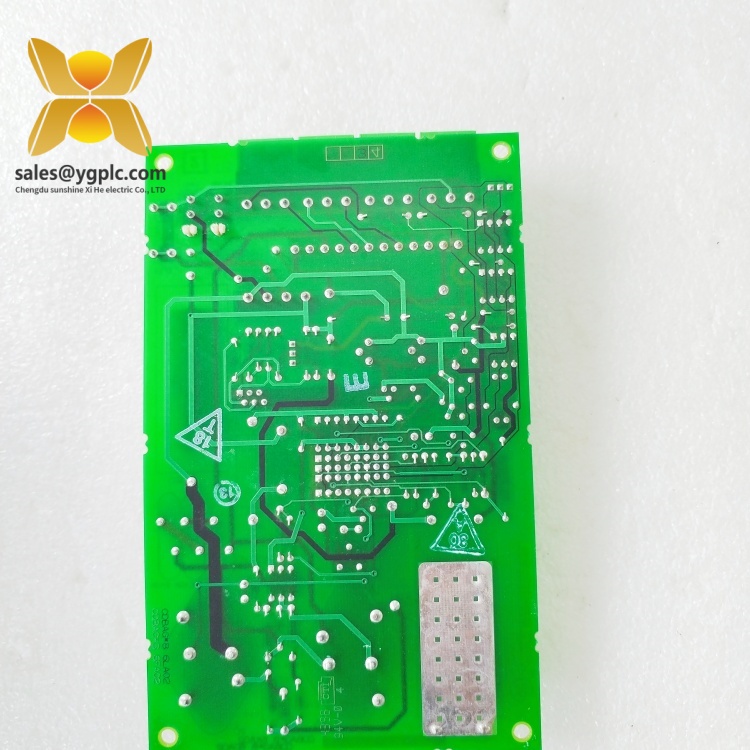

The GE DS200RTBAG5A is a high-reliability Relay Output Module designed for use in GE’s Speedtronic Mark VIe control system, a leading platform for turbine and generator control in power generation and industrial applications. Engineered to deliver precise switching commands to field devices, this module converts digital control signals from the Mark VIe controller into physical relay actions, enabling the management of critical processes such as valve actuators, motor starters, and alarm systems. As part of the DS200 Series, the DS200RTBAG5A ensures seamless integration with other Mark VIe components, providing a robust solution for mission-critical automation tasks.

The GE DS200RTBAG5A features 16 independent relay outputs, each capable of handling high-current loads up to 5 A at 250 VAC/30 VDC, making it suitable for both low-power control circuits and direct actuation of industrial equipment. Its fail-safe design includes redundant power inputs and LED status indicators for each channel, allowing real-time monitoring of relay health and contact status. The module’s compatibility with the Mark VIe’s Proficy software suite enables remote configuration, diagnostics, and firmware updates, reducing maintenance downtime and enhancing system flexibility.

In automation ecosystems, the DS200RTBAG5A serves as a critical interface between the digital control system and analog field devices, providing galvanic isolation to protect sensitive electronics from voltage spikes and electrical noise. Its rugged construction, compliant with IEC 61131-2 standards, ensures reliable operation in harsh environments with extreme temperatures, vibration, and electromagnetic interference, making it ideal for power plants, refineries, and heavy industrial facilities.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200RTBAG5A |

| Manufacturer | GE |

| Product Type | Relay Output Module |

| Platform | Speedtronic Mark VIe |

| Output Channels | 16 Form C (SPDT) electromechanical relays |

| Contact Rating | 5 A @ 250 VAC / 30 VDC |

| Switching Speed | <10 ms (typical) |

| Power Supply | 24 V DC ±10% (redundant inputs) |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.9 kg |

| Operating Temperature | -40°C to +85°C |

| Certifications | CE, UL, CSA |

| Mounting | Rack-mounted in Mark VIe enclosure |

| Communication | Proprietary Mark VIe bus |

Key Features and Advantages

High-Current Switching Capability: The DS200RTBAG5A’s 5 A contact rating allows direct control of high-power devices, eliminating the need for external relay modules in many applications. This simplifies system design, reduces component count, and lowers installation costs.

Fail-Safe Redundancy: With redundant power inputs and self-diagnostic capabilities, the module ensures continuous operation even in the event of power supply failures or internal faults. LED indicators on each channel provide visual confirmation of relay status, enabling quick troubleshooting and minimizing downtime.

Galvanic Isolation: Each relay output is isolated from the control system and other channels, protecting against electrical noise and voltage transients. This isolation enhances system reliability and safeguards sensitive control electronics from damage.

Hot-Swap Capability: The module can be replaced while the system is operational, allowing for maintenance or upgrades without interrupting critical processes. This feature is particularly valuable in 24/7 industrial environments where downtime is costly.

Scalable Integration: As part of the Mark VIe ecosystem, the DS200RTBAG5A seamlessly integrates with GE’s suite of control and monitoring tools, enabling centralized configuration and real-time status monitoring. This integration enhances system visibility and simplifies maintenance.

Rugged Industrial Design: Built to withstand harsh industrial environments, the module meets rigorous standards for vibration, shock, and temperature extremes, ensuring reliable performance in demanding applications such as power generation and oil & gas processing.

Application Areas

The GE DS200RTBAG5A is widely used in applications requiring reliable switching control:

- Power Generation: Controls turbine bypass valves, generator circuit breakers, and auxiliary equipment in thermal, hydro, and gas power plants, ensuring safe and efficient operation.

- Oil & Gas: Manages solenoid valves, pump starters, and safety shutdown systems in upstream drilling, midstream pipelines, and downstream refining operations.

- Manufacturing: Controls conveyor systems, robotic actuators, and process equipment in automotive, food & beverage, and pharmaceutical manufacturing plants.

- Water/Wastewater: Operates pumps, valves, and aeration systems in treatment facilities, ensuring proper flow control and process automation.

Specific applications include:

- Turbine Control: Provides discrete outputs for turbine lube oil pumps, turning gear engagement, and emergency shutdown systems, ensuring safe and reliable turbine operation.

- Alarm and Annunciation: Activates audible and visual alarms in response to process deviations or system faults, alerting operators to potential issues.

- Motor Control: Switches high-power motor starters in industrial applications, providing reliable on/off control for pumps, fans, and compressors.

Related Products

- DS200RTBAG1A: An earlier version of the relay output module with similar functionality, offering backward compatibility for legacy systems.

- DS200DIOLH2A: Digital input/output module that complements the DS200RTBAG5A by providing additional discrete I/O channels for Mark VIe systems.

- DS200DOLCH1A: Digital output module with solid-state relays for applications requiring faster switching speeds and higher cycle life.

- DS200ALGCG1A: Algorithm module that processes control logic and communicates with the DS200RTBAG5A to execute switching commands.

- DS200TCTGG1A: Turbine control module that works in conjunction with the DS200RTBAG5A to manage turbine operations in power generation applications.

- DS200TBCH: Terminal block module that simplifies field wiring for the DS200RTBAG5A, providing a secure and organized connection point for external devices.

- DS200PWR: Power supply module that provides redundant power to the Mark VIe rack, ensuring uninterrupted operation of the DS200RTBAG5A.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE DS200RTBAG5A, ensure the Mark VIe rack is properly grounded and powered off. Verify that the module’s part number matches the system requirements and that all required accessories (e.g., terminal blocks) are available. Use appropriate personal protective equipment (PPE) when handling the module. Mount the module in the rack, aligning it with the guide rails and securing it with the provided fasteners. Connect the redundant power inputs and field wiring to the terminal block, following the manufacturer’s wiring diagrams to ensure proper polarity and signal integrity.

Before installing the GE DS200RTBAG5A, ensure the Mark VIe rack is properly grounded and powered off. Verify that the module’s part number matches the system requirements and that all required accessories (e.g., terminal blocks) are available. Use appropriate personal protective equipment (PPE) when handling the module. Mount the module in the rack, aligning it with the guide rails and securing it with the provided fasteners. Connect the redundant power inputs and field wiring to the terminal block, following the manufacturer’s wiring diagrams to ensure proper polarity and signal integrity.

Maintenance Suggestions:

- Routine Inspections: Periodically check the module’s LED indicators to verify normal operation. Inspect terminal connections for tightness and signs of corrosion or overheating. Clean the module’s exterior to remove dust and debris that could affect heat dissipation.

- Relay Testing: Perform annual relay contact resistance tests using a multimeter to ensure contacts are within specification. Replace any relays showing signs of excessive wear or contact degradation.

- Firmware Updates: Regularly update the module’s firmware using GE’s Proficy software to incorporate bug fixes and enhancements. Follow the manufacturer’s recommended procedures to ensure a successful update.

- Spare Parts Management: Keep spare DS200RTBAG5A modules and replacement relays in a controlled environment to prevent damage from static electricity, moisture, or physical impact.

Product Guarantee

Our company provides a 12-month quality warranty for the GE DS200RTBAG5A, covering hardware defects under normal use. In the event of unexpected failures, we offer prompt replacement services to minimize downtime. For legacy or discontinued models like the DS200RTBAG5A, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, delivering tailored solutions to maintain your system’s integrity and performance.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE DS200SDCCGIAGD Output module

GE DS200SHVG1BGD High density main box

GE DS200SHVIG1BHD Remote extender module

GE DS200SHVMGIA Input pulse module

GE DS200SLCCG1ABB Digital output module

GE DS200SLCCG3ACC Digital relay output module

GE DS200SLCCG3ADC Output module digit

GE DS200TBCAG1AAB PXI module

GE DS200TBCBGIAAA Servo drive

GE DS200TBOFG1A Servo motor

GE DS200TBPAG1A Industrial keyboard

中文版

中文版