Product Overview

The GE DS200SDCCG1AEC is a high-performance control module engineered by General Electric (GE) as part of its renowned Speedtronic series, designed to deliver precision control and reliability in critical industrial automation systems. This advanced module serves as a core component in turbine control systems, particularly for steam and gas turbines, where it manages speed, load, and process variables with exceptional accuracy. As a key player in GE’s portfolio of industrial control solutions, the GE DS200SDCCG1AEC integrates seamlessly with distributed control systems (DCS) and programmable logic controllers (PLCs), enabling seamless coordination between mechanical and electrical components in power generation, oil and gas, and heavy manufacturing environments.

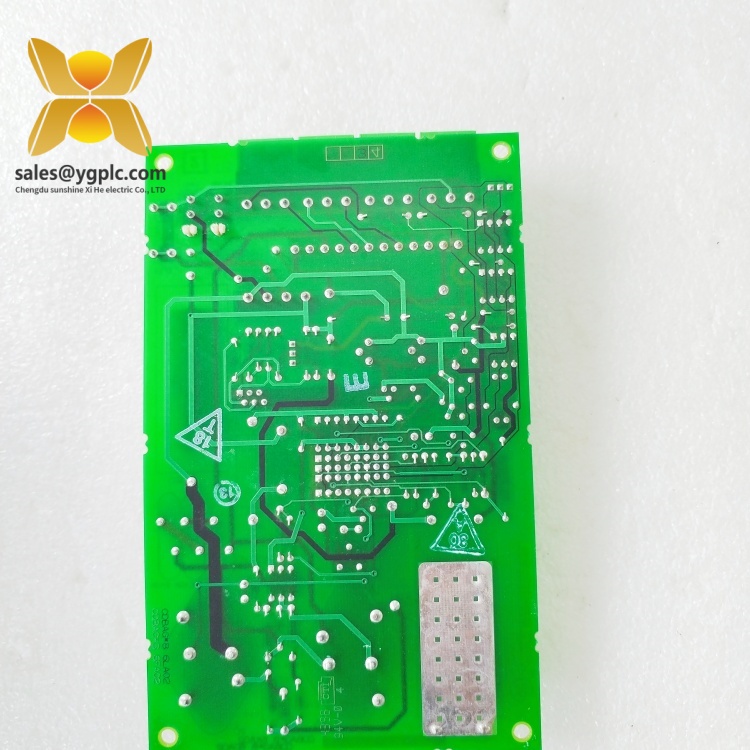

Featuring a robust design and state-of-the-art microprocessor technology, the GE DS200SDCCG1AEC excels in processing real-time data, executing complex control algorithms, and communicating with external devices to ensure optimal system performance. Its modular architecture allows for easy integration into existing setups, while built-in diagnostic capabilities minimize downtime by identifying and alerting operators to potential issues. Positioned as a mission-critical component in safety-critical systems, this module enhances operational efficiency by reducing energy consumption, improving response times, and supporting predictive maintenance strategies. For industries reliant on continuous, high-stakes operations, the GE DS200SDCCG1AEC embodies GE’s commitment to innovation, providing a durable and future-proof solution that withstands harsh industrial conditions while driving operational excellence.

Technical Specifications

| Parameter Name | Parameter Values |

|---|---|

| Manufacturer | General Electric (GE) |

| Product Type | Turbine Control Module |

| Electrical Specifications | Input Voltage: 24 V DC ±10%, Power Consumption: 50 W max |

| Physical Dimensions | 10.5 in (266.7 mm) x 8.25 in (209.6 mm) x 3.5 in (88.9 mm) |

| Weight | 4.8 lbs (2.18 kg) |

| Origin | United States |

| Interface Type | RS-485, Ethernet (10/100 Mbps), Analog/Digital I/O |

| Communication Protocol | Modbus TCP, Profibus DP, GE Genius Bus |

| Working Temperature | -40°C to 70°C (-40°F to 158°F) |

| Humidity Range | 5% to 95% non-condensing |

| Installation Type | Rack-mounted (DIN rail compatible) |

Main Features and Advantages

The GE DS200SDCCG1AEC stands out for its advanced control capabilities and rugged design, making it an ideal choice for industries demanding uncompromising performance. One of its primary strengths is its real-time data processing power, which enables precise regulation of turbine speed and load through adaptive control algorithms. This ensures stable operation even in fluctuating grid conditions or varying process demands, reducing wear and tear on mechanical components and extending equipment lifespan.

Another key advantage is the module’s comprehensive diagnostic suite, which continuously monitors internal functions and external connections. Built-in self-test routines and fault detection mechanisms identify anomalies such as communication failures, voltage fluctuations, or sensor discrepancies, allowing maintenance teams to address issues proactively. This predictive capability minimizes unplanned outages and supports lean maintenance strategies, ultimately lowering operational costs.

The GE DS200SDCCG1AEC also excels in interoperability, with multiple communication interfaces that facilitate seamless integration with legacy and modern control systems. Its support for industry-standard protocols like Modbus and Profibus ensures compatibility with a wide range of devices, while the GE Genius Bus interface enables efficient data exchange within GE’s ecosystem of automation products. This flexibility makes the module suitable for retrofitting older systems or deploying in cutting-edge smart industrial setups.

Additionally, the module’s robust construction ensures reliability in harsh environments. Rated for operation in extreme temperatures and high-humidity conditions, it features reinforced circuitry and anti-vibration mounting, making it suitable for use in power plants, refineries, and other industrial settings where environmental challenges are common. Its compliance with international safety standards further underscores its suitability for safety-instrumented systems (SIS), providing peace of mind in applications where failure tolerance is critical.

Application Fields

The GE DS200SDCCG1AEC finds wide-ranging applications in industries reliant on turbine-driven power generation and process control. In power plants, it serves as a central component in steam turbine control systems, managing speed governors and load sharing to ensure consistent electricity supply. Its ability to interface with boiler control systems and grid management networks makes it indispensable for balancing power output with demand, optimizing fuel efficiency, and reducing emissions in combined-cycle power plants.

In the oil and gas sector, the module is deployed in gas turbine-driven compressor stations, where it regulates turbine speed to maintain optimal pressure and flow rates in pipelines. Its rugged design and resistance to electromagnetic interference make it suitable for offshore platforms and remote installations, where reliability is non-negotiable. Additionally, the GE DS200SDCCG1AEC supports emergency shutdown (ESD) systems, providing rapid response to safety incidents and ensuring compliance with stringent industry regulations.

Heavy manufacturing industries, such as steel and chemical production, leverage the module’s precision control capabilities in steam turbine-driven machinery. It enables precise adjustment of process variables like temperature and pressure in refining and distillation units, enhancing product quality and reducing waste. The module’s diagnostic features also play a crucial role in predictive maintenance programs, helping manufacturers avoid costly downtime and maintain production schedules.

Furthermore, the GE DS200SDCCG1AEC is well-suited for combined heat and power (CHP) systems, where it optimizes energy recovery and distribution in industrial and commercial settings. By integrating with building automation systems, it ensures efficient use of thermal energy, supporting sustainability goals and reducing carbon footprints.

Related Products

- GE DS200TCTGG1A (Turbine Control Module): A predecessor model in GE’s Speedtronic series, offering basic control functions for simpler turbine setups.

- GE DS3800NPCC1B (Network Processor Module): Works in tandem with the GE DS200SDCCG1AEC to manage network communications in distributed control systems.

- GE IS200TBDBH1B (Turbine Bearing Diagnostic Module): Complementary module for monitoring bearing health, enhancing the predictive maintenance capabilities of the system.

- GE DS200SLCCG1A (Speed/Load Control Module): Focused on speed and load regulation, ideal for applications requiring basic control without advanced diagnostics.

- GE DS4000 Series: Upgraded control modules with enhanced processing power and connectivity, suitable for modernization projects replacing older GE DS200SDCCG1AEC systems.

- GE IS200TCCBH1B (Turbine Control Circuit Board): Spare component designed for maintenance and replacement in GE turbine control systems.

- GE DS200DCFBG1A (Digital Control Feedback Module): Provides feedback control for digital systems, enhancing the accuracy of the GE DS200SDCCG1AEC.

- GE Speedtronic Mark VIe: A comprehensive control platform that integrates with the GE DS200SDCCG1AEC for advanced turbine management.

Installation and Maintenance

Pre-installation Preparations: Before installing the GE DS200SDCCG1AEC, ensure the control cabinet is properly grounded and free of dust or debris. Verify that the power supply matches the module’s electrical specifications (24 V DC ±10%) and that all communication cables are shielded to prevent interference. Plan the rack mounting layout to allow adequate airflow for cooling, as the module operates optimally within a specified temperature range. Connect all input/output signals according to the wiring diagram provided in the product manual, ensuring secure connections to sensors, actuators, and network devices.

Maintenance Suggestions: Regular maintenance of the GE DS200SDCCG1AEC involves periodic inspections of connection terminals for looseness or corrosion, particularly in high-humidity environments. Clean the module’s exterior with a dry, static-free cloth to prevent dust accumulation that could affect heat dissipation. Use the built-in diagnostic software to run self-tests at scheduled intervals, checking for firmware updates or error codes that may indicate component wear. For firmware upgrades, follow GE’s recommended procedures to avoid data loss or system instability. In the event of a fault, replace the module with a certified spare part and retain the faulty unit for professional repair or analysis.

Product Guarantee

Our company, a leading industrial control solutions provider established in 2007, stands behind the GE DS200SDCCG1AEC with a comprehensive one-year quality warranty. This warranty covers hardware malfunctions arising from manufacturing defects, excluding damage caused by improper installation, misuse, or natural disasters. During the warranty period, we will promptly replace any defective module to minimize disruption to your operations. Beyond warranty services, our global supply chain network enables us to source hard-to-find and obsolete industrial control parts, including discontinued models like the GE DS200SDCCG1AEC, ensuring rapid response to urgent procurement needs.

As an import-export distribution company specializing in industrial control spare parts, we maintain a large inventory of genuine components, including rare and legacy models, to support our clients’ maintenance and modernization projects. Our team of technical experts provides pre-sales consulting and after-sales support, assisting with system integration, troubleshooting, and firmware updates. Whether you require a single module or a complete control system upgrade, we are committed to delivering reliable products and services that ensure the continuous, stable operation of your industrial infrastructure. For inquiries, contact us via our official website, phone, or email to receive competitive quotations and personalized solutions.

Whatsapp: +86 18859254943

E-mail: sales@ygplc.com

E-mail: sales@ygplc.com

GE DS200TBQDGIACC Control cabinet node unit

GE DS200TBQDGIAEE governor

GE DS200TBQDGIAFF Input module

GE DS200TBQEG1B AI/AO/DI/DO module

GE DS200TBQGG1A Servo valve

GE DS200TCCAG1B Analog input

GE DS200TCCAG2A Digital output

GE DS200TCCAG2AHB Program module

GE DS200TCCAG2B Ethernet

GE DS200TCCAGIACA Integrated protection device

GE DS200TCCAGIAHB Connecting module

GE DS200TCCBG1B driver

GE DS200TCCBG3A servo

GE DS200TCCBG3ANE Eddy current sensor

中文版

中文版