Product Overview

The is a high-performance relay terminal board engineered by General Electric (GE) for critical industrial automation applications. As a core component of the Mark V series and EX2000 excitation control systems, the GE DS200RTBAG4A serves as a versatile interface between controllers and external devices, ensuring precise signal relay and power management in turbine control, power generation, and industrial process environments. This board is designed to handle demanding scenarios where reliability and accuracy are paramount, making it an indispensable asset for maintaining seamless operations in complex systems.

The is a high-performance relay terminal board engineered by General Electric (GE) for critical industrial automation applications. As a core component of the Mark V series and EX2000 excitation control systems, the GE DS200RTBAG4A serves as a versatile interface between controllers and external devices, ensuring precise signal relay and power management in turbine control, power generation, and industrial process environments. This board is designed to handle demanding scenarios where reliability and accuracy are paramount, making it an indispensable asset for maintaining seamless operations in complex systems.

Featuring ten high-quality relays, the GE DS200RTBAG4A offers flexibility in voltage configurations, supporting 115V AC, 24V DC, and 110V DC inputs. Three of its relays are equipped with four Form C contacts (rated at 5A), while the remaining seven feature two Form C contacts (rated at 10A), allowing it to manage both low- and high-current applications with ease. The board’s robust design includes surge protection through metal oxide varistors (MOVs) and Berg-type jumpers for configurable signal routing, ensuring compatibility with a wide range of industrial setups. By integrating the GE DS200RTBAG4A, users can enhance system scalability, reduce downtime, and optimize control logic in their automation infrastructure.

As part of GE’s legacy Mark V series, the GE DS200RTBAG4A leverages patented Speedtronic control technology to deliver stable performance in harsh industrial conditions. Its modular architecture enables straightforward integration with other GE components, such as the LTB (LAN Terminal Board), facilitating efficient communication between controllers and field devices. Whether used in simplex, dual, or triple-redundant systems, this relay terminal board ensures reliable signal transmission and fault isolation, contributing to the overall resilience of industrial control systems. The GE DS200RTBAG4A is a testament to GE’s commitment to innovation, combining advanced engineering with user-centric design to meet the evolving needs of modern industrial automation.

Technical Specifications

- Manufacturer: General Electric (GE)

- Product type: Relay Terminal Board

- Series: Mark V / EX2000

- Physical dimensions: 17.51 cm (height) x 18.5 cm (width) 117

- Weight: 2.00 lbs (0.91 kg) 117

- Coil voltage: 115V AC (50/60 Hz), 24V DC, 110V DC 117

- Relay configuration: 10 relays (3 with 4 Form C contacts, 7 with 2 Form C contacts) 117

- Contact ratings: 5A (4 Form C) / 10A (2 Form C) 117

- Input/output interface: 16-pin RPL connector, 2-pin OPT PL connector 1

- Communication protocol: Proprietary GE interface for integration with Mark V systems 117

- Operating temperature: -40°C to +85°C (industrial grade) 13

- Place of origin: United States 117

Main Features and Advantages

The GE DS200RTBAG4A stands out for its versatile relay configuration, which allows it to adapt to diverse industrial requirements. With ten relays supporting multiple voltage inputs, the board can simultaneously manage control signals, alarms, and power outputs, reducing the need for additional hardware. This flexibility is further enhanced by its configurable jumpers, which enable users to customize signal routing and power sourcing according to their specific application needs. For example, the board’s control power can be derived from either the LTB or external sources, providing redundancy and operational agility 1.

The GE DS200RTBAG4A stands out for its versatile relay configuration, which allows it to adapt to diverse industrial requirements. With ten relays supporting multiple voltage inputs, the board can simultaneously manage control signals, alarms, and power outputs, reducing the need for additional hardware. This flexibility is further enhanced by its configurable jumpers, which enable users to customize signal routing and power sourcing according to their specific application needs. For example, the board’s control power can be derived from either the LTB or external sources, providing redundancy and operational agility 1.

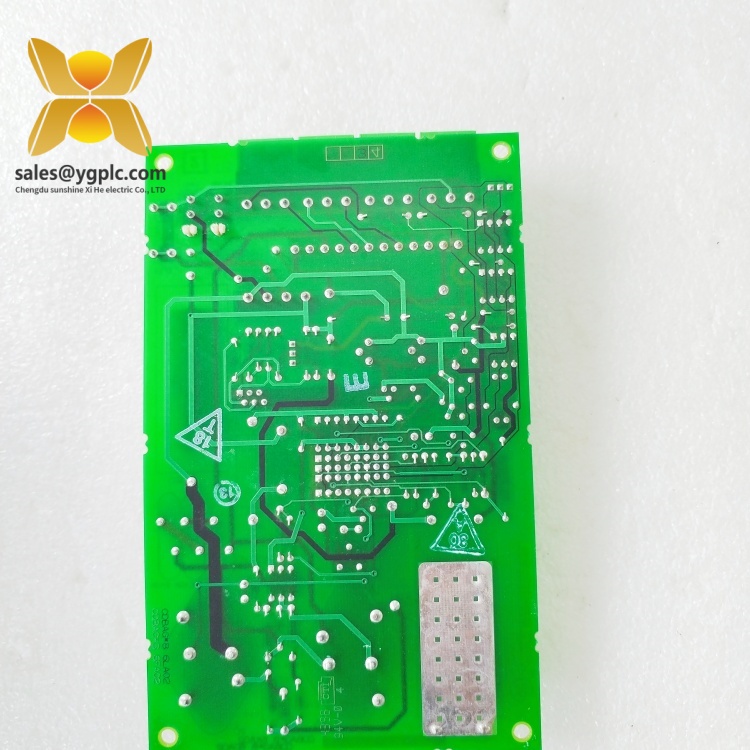

Reliability is a cornerstone of the GE DS200RTBAG4A’s design. Each relay is equipped with a state indicator lamp and surge-protective MOVs, ensuring real-time status monitoring and protection against voltage spikes. The board’s multilayer PCB construction and industrial-grade components withstand extreme temperatures, humidity, and vibration, making it suitable for deployment in harsh environments such as power plants, oil refineries, and manufacturing facilities 1317. Additionally, its compatibility with GE’s Mark V and EX2000 systems ensures seamless integration with existing infrastructure, minimizing retrofitting costs and downtime.

Maintenance and troubleshooting are streamlined through the GE DS200RTBAG4A’s modular design. Relays are individually replaceable, and the board’s diagnostic capabilities allow for quick fault isolation. This reduces repair time and ensures that critical systems remain operational. Furthermore, the board’s ESD (electrostatic discharge) protection and anti-static packaging during shipping safeguard against damage, extending its service life and maintaining consistent performance 1317.

Application Fields

The GE DS200RTBAG4A finds extensive use in turbine control systems, where it plays a pivotal role in managing excitation, load shedding, and safety interlocks. In gas, steam, and wind turbine applications, the board relays signals between the Speedtronic controller and field devices such as contactors, indicators, and pushbuttons, ensuring precise speed and power regulation 117. Its high-current handling capability makes it ideal for activating solenoids and other heavy-duty components in these systems.

The GE DS200RTBAG4A finds extensive use in turbine control systems, where it plays a pivotal role in managing excitation, load shedding, and safety interlocks. In gas, steam, and wind turbine applications, the board relays signals between the Speedtronic controller and field devices such as contactors, indicators, and pushbuttons, ensuring precise speed and power regulation 117. Its high-current handling capability makes it ideal for activating solenoids and other heavy-duty components in these systems.

In power generation plants, the GE DS200RTBAG4A supports critical functions like generator protection, voltage regulation, and grid synchronization. By interfacing with the EX2000 excitation system, it ensures stable power output and protects against overloads or short circuits 113. The board’s redundancy features also make it suitable for safety-instrumented systems (SIS) and emergency shutdown (ESD) applications, where fail-safe operation is non-negotiable.

Industrial automation processes, including oil and gas production and chemical manufacturing, benefit from the GE DS200RTBAG4A’s ability to integrate with distributed control systems (DCS). It facilitates real-time monitoring and control of valves, pumps, and motors, optimizing production efficiency while adhering to strict safety standards. The board’s compatibility with legacy GE systems ensures that it can be retrofitted into older installations, providing modern functionality without full system overhauls 113.

Related Products

- GE DS200RTBAG1A: A predecessor model with a 110V DC coil and 10A contacts, suitable for lower-voltage applications 15.

- GE DS200RTBAG2A: Features dual-coil relays for enhanced redundancy in critical systems 5.

- GE DS200RTBAG3A: Optimized for high-frequency switching in motor control applications 5.

- GE DS200RTBAG5A: Offers extended temperature range for extreme industrial environments 16.

- GE LTB (LAN Terminal Board): Works in tandem with the GE DS200RTBAG4A to provide additional I/O channels and pilot relay functionality 117.

- GE EX2000 Excitation System: The GE DS200RTBAG4A is a key component of this system, supporting generator voltage control and stability 113.

Installation and Maintenance

Pre-installation preparations: Before installing the GE DS200RTBAG4A, ensure the system is powered off and all ESD precautions are observed. Verify that the board’s physical dimensions (17.51 cm x 18.5 cm) match the mounting location and that the voltage requirements (115V AC, 24V DC, or 110V DC) align with the control power source. Inspect the connectors for damage and ensure proper grounding to prevent electrical interference 113.

Pre-installation preparations: Before installing the GE DS200RTBAG4A, ensure the system is powered off and all ESD precautions are observed. Verify that the board’s physical dimensions (17.51 cm x 18.5 cm) match the mounting location and that the voltage requirements (115V AC, 24V DC, or 110V DC) align with the control power source. Inspect the connectors for damage and ensure proper grounding to prevent electrical interference 113.

Maintenance suggestions: Regularly clean the GE DS200RTBAG4A to remove dust and debris, as accumulated particles can affect performance. Check the relay contacts for wear or oxidation, replacing them if necessary. Test the board’s functionality using GE’s recommended diagnostics tools to identify any faults. For long-term storage, keep the board in an anti-static environment and periodically perform power-on tests to maintain component integrity 1317.

Product Guarantee

Our company, a leading industrial control parts distributor established in 2007, offers a one-year quality warranty for the GE DS200RTBAG4A, covering hardware malfunctions unrelated to improper use or environmental damage. During the warranty period, we provide prompt replacement services for any defective units. For discontinued models or urgent requirements, our global supply chain network ensures rapid fulfillment of scarce spare parts, minimizing downtime and supporting uninterrupted industrial operations. With a vast inventory of new, refurbished, and obsolete components, we are committed to delivering reliable solutions that meet the highest standards of quality and performance. Contact us today to explore how the GE DS200RTBAG4A can enhance your automation system’s efficiency and reliability.

Our company, a leading industrial control parts distributor established in 2007, offers a one-year quality warranty for the GE DS200RTBAG4A, covering hardware malfunctions unrelated to improper use or environmental damage. During the warranty period, we provide prompt replacement services for any defective units. For discontinued models or urgent requirements, our global supply chain network ensures rapid fulfillment of scarce spare parts, minimizing downtime and supporting uninterrupted industrial operations. With a vast inventory of new, refurbished, and obsolete components, we are committed to delivering reliable solutions that meet the highest standards of quality and performance. Contact us today to explore how the GE DS200RTBAG4A can enhance your automation system’s efficiency and reliability.

For inquiries, please contact us via WhatsApp at +86 18859254943 or email sales@ygplc.com.

GE DS200TBQDGIAEE System

GE DS200TBQDGIAFF DCS

GE DS200TBQEG1B Network communication module

GE DS200SLCCG3ACC Board interface module

GE DS200SLCCG3ADC Fault-tolerant board

GE DS200SLCCG3AEE Power module

GE DS200SLCCG3AEF Cable/terminal/Matching

GE DS200RTBAG4A Control board terminal

GE DS200RTBAG5A Dual output module

GE DS200SDCCG1AEC External control board terminates

GE DS200SDCCG1AHD Digital input terminal panel

GE DS200SDCCG4AFD board card

GE DS200SDCCG4AGD DO card

中文版

中文版