GE DS200QTBAG1ADC Mark VIe Terminal Block Interface Module

Product Overview

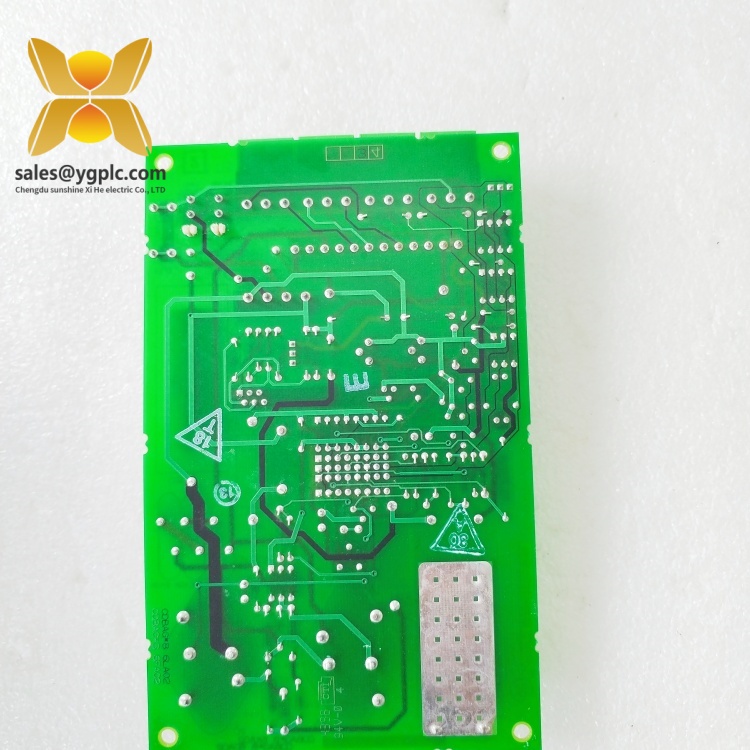

The GE DS200QTBAG1ADC is a high-reliability Terminal Block Interface Module designed as a critical connectivity component for GE’s Mark VIe distributed control system (DCS), serving industrial automation and machinery protection applications. As part of the DS200 Series, this module acts as the physical interface between field devices (e.g., sensors, actuators) and the Mark VIe control platform, ensuring secure and noise-immune signal transmission in harsh industrial environments. Engineered for seamless integration into GE’s turbine and process control ecosystems, the DS200QTBAG1ADC plays a pivotal role in power generation, oil & gas, and manufacturing sectors by facilitating reliable data exchange and control signal routing.

Featuring a rugged industrial design, the GE DS200QTBAG1ADC supports a wide range of analog and digital signals, with configurable terminal blocks for easy field wiring. Its modular architecture allows for quick replacement during maintenance, while built-in surge protection and electromagnetic compatibility (EMC) compliance ensure stable performance in high-noise environments, such as those with motor drives or high-voltage equipment. The module’s compatibility with GE’s Proficy software and Mark VIe rack system enables centralized configuration and diagnostics, reducing engineering time and enhancing system maintainability.

In automation systems, the DS200QTBAG1ADC serves as the backbone for field device connectivity, converting raw signals from proximity probes, thermocouples, or relays into standardized inputs/outputs for the Mark VIe controller. Its hot-swappable design ensures continuous operation during module replacement, making it indispensable for 24/7 industrial operations where downtime is costly. By combining robust signal conditioning with user-friendly installation, this module optimizes system reliability and reduces the risk of connectivity-related failures in mission-critical applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200QTBAG1ADC |

| Manufacturer | GE |

| Product Type | Terminal Block Interface Module |

| Platform | Mark VIe |

| Signal Types | Analog (4–20 mA, 0–10 V DC), digital (dry contacts, TTL/CMOS) |

| Terminal Type | Screw-down terminals (M3/M4 compatible) |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.5 kg |

| Power Supply | Derived from Mark VIe rack (24 V DC) |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted (19-inch standard, compatible with Mark VIe enclosures) |

| EMC Compliance | IEC 61000-6-2 (industrial immunity), IEC 61000-6-4 (emission standards) |

| Shock/Vibration | IEC 60068-2-27 (50 g peak shock), IEC 60068-2-6 (2 g RMS vibration) |

Key Features and Advantages

Field Wiring Simplification: The DS200QTBAG1ADC streamlines field device integration with its standardized terminal block layout, supporting up to [X] channels of mixed signal types. This reduces wiring complexity and minimizes installation errors, the module ensures secure connections that withstand industrial vibrations and temperature fluctuations.

Hot-Swap Capability: Designed for maintenance efficiency, the module can be replaced without powering down the Mark VIe system, enabling live upgrades or repairs. This feature is critical for reducing unplanned downtime in continuous production environments.

Robust Signal Isolation: Built-in galvanic isolation (250 V RMS) between channels prevents ground loops and electromagnetic interference (EMI), ensuring signal integrity even in high-noise settings. This reliability is essential for accurate data transmission in control loops and safety-critical applications.

Modular Scalability: As part of the Mark VIe ecosystem, the DS200QTBAG1ADC can be paired with other DS200 Series modules (e.g., analog inputs, digital outputs) to create scalable I/O configurations. This flexibility allows systems to adapt to changing process requirements without major redesigns.

Industrial-Grade Durability: The module’s metal enclosure and conformal-coated circuitry meet rigorous environmental standards, making it suitable for offshore platforms, refineries, and power plants. Its wide temperature range and shock/vibration resistance ensure long-term performance in harsh operating conditions.

Integrated Diagnostics: LED indicators provide real-time status feedback (e.g., power, channel activity), while the Mark VIe system’s diagnostic software alerts operators to wiring faults or signal anomalies. This proactive approach reduces troubleshooting time and enhances system availability.

Application Areas

The GE DS200QTBAG1ADC is widely deployed in industries requiring reliable field device connectivity and robust signal management:

- Power Generation: Connects sensors and actuators in steam turbines, gas generators, and boiler systems, enabling real-time monitoring of parameters like temperature, pressure, and speed. Critical for turbine control systems and generator protection relays.

- Oil & Gas: Facilitates connectivity for wellhead control systems, pipeline pressure transmitters, and emergency shutdown (ESD) valves in upstream, midstream, and downstream operations. Supports compliance with API and IEC safety standards.

- Manufacturing: Used in automotive, chemical, and food processing plants to interface with conveyor belt sensors, motor drives, and safety interlocks, ensuring precise control and compliance with production protocols.

- Water/Wastewater Treatment: Connects flow meters, level sensors, and pump actuators in treatment facilities, enabling automated control of filtration, disinfection, and distribution processes.

Specific applications include:

- Turbine Protection Systems: Routes vibration sensor signals from proximity probes to the Mark VIe controller for real-time shaft health analysis.

- Process Automation: Supports PID control loops by connecting analog signals from flow meters to control valves, optimizing process efficiency.

- Safety Instrumented Systems (SIS): Provides reliable connectivity for fire & gas detectors and shutdown actuators, meeting SIL 3 requirements under IEC 61511.

Related Products

- DS200AAHAH2ADC (Analog Input Module): Works alongside the DS200QTBAG1ADC to convert analog signals from field devices into digital data for the Mark VIe controller.

- DS200AASA (Analog Output Module): Transmits control signals from the controller to actuators, forming a closed-loop system with the DS200QTBAG1ADC.

- DS200DDAIG1A (Digital Input Module): Complements the module by handling discrete signals (e.g., switch states, relay contacts) in mixed I/O configurations.

- DS200DORA (Digital Output Relay Module): Provides relay-based outputs for controlling motors or valves, integrated via the DS200QTBAG1ADC terminal blocks.

- DS200PWR (Redundant Power Supply Module): Ensures uninterrupted power to the Mark VIe rack, supporting the DS200QTBAG1ADC in redundant system designs.

- DS200COMM (Ethernet Communication Module): Enables remote monitoring and control by linking the DS200QTBAG1ADC to SCADA systems via Ethernet/IP or Modbus TCP.

- DS200TBCH (Terminal Block Chassis): Provides additional terminal block capacity for large-scale I/O applications, expandable alongside the DS200QTBAG1ADC.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE DS200QTBAG1ADC, verify that the Mark VIe rack is properly grounded and ventilated. Ensure the module’s terminal block configuration matches the signal types of connected devices (e.g., analog for transmitters, digital for switches). Use shielded cables for analog signals and twisted-pair wiring for digital signals to minimize EMI. Secure the module in the rack using the provided hardware, ensuring alignment with the backplane connectors for seamless communication with the Mark VIe controller.

Before installing the GE DS200QTBAG1ADC, verify that the Mark VIe rack is properly grounded and ventilated. Ensure the module’s terminal block configuration matches the signal types of connected devices (e.g., analog for transmitters, digital for switches). Use shielded cables for analog signals and twisted-pair wiring for digital signals to minimize EMI. Secure the module in the rack using the provided hardware, ensuring alignment with the backplane connectors for seamless communication with the Mark VIe controller.

Maintenance Suggestions:

- Routine Inspections: Monthly checks should include verifying terminal block tightness, LED status indicators, and cable integrity. Use GE’s Proficy software to review module diagnostics for any fault codes related to connectivity or signal quality.

- Environmental Maintenance: Clean the module’s vents and terminals quarterly to prevent dust or debris accumulation, which can affect heat dissipation and electrical connections. In high-humidity environments, inspect for corrosion on terminal surfaces.

- Firmware Updates: Periodically update the Mark VIe system firmware (including the DS200QTBAG1ADC) to incorporate bug fixes and compatibility improvements, following GE’s validated procedures to avoid system disruptions.

- Spare Parts Management: Store spare DS200QTBAG1ADC modules in anti-static packaging at room temperature (20–25°C) with low humidity (<50%). Test spares annually to ensure functionality, particularly for critical applications where rapid replacement is essential.

Product Guarantee

Our company provides a 12-month quality warranty for the GE DS200QTBAG1ADC, covering hardware defects under normal use. In the event of terminal block failures, connectivity issues, or component malfunctions, we offer prompt replacement services to minimize operational downtime. For legacy or discontinued models like the DS200QTBAG1ADC, our global supply chain network specializes in sourcing rare industrial control parts, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation guidance, wiring diagrams, and troubleshooting, ensuring seamless integration and long-term reliability of your Mark VIe system.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE DS200QTBAG1ADC Dual digital output module

GE DS200RTBAG4A Card piece

GE DS200RTBAG5A convertor

GE DS200SHVMGIA sensor

GE DS200SLCCG1ABB Master control panel

GE DS200SLCCG3ACC Switch input module

GE DS200SLCCG3ADC AO connection card

GE DS200SLCCG3AEE Digital output terminal board

GE DS200SLCCG3AEF Logic control module

GE DS200SLCCG3AFG Switch input terminal board

GE DS200SLCCG3AGH I/O fault diagnosis

GE DS200SLCCGIAEF DCS module

GE DS200STCAG1A AO card

中文版

中文版