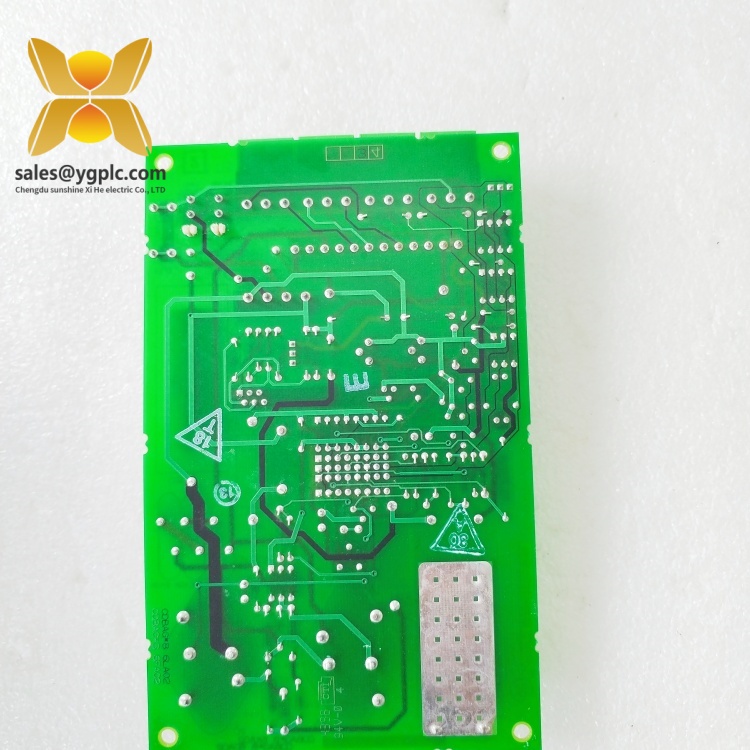

GE DS200QTBAG1ACB RST Termination Board

Product Overview

The GE DS200QTBAG1ACB is a high-performance RST (Remote Signal Termination) termination board designed for critical industrial automation applications within GE’s Speedtronic Mark V gas turbine control system. As a core component of this legacy yet highly reliable series, the GE DS200QTBAG1ACB serves as a vital interface for signal integration, transmission, and system monitoring, ensuring seamless communication between field devices and control modules. Its robust design and precise engineering make it an indispensable asset in power generation, oil and gas, and industrial process control environments where system uptime and accuracy are paramount.

In the Mark V system, the GE DS200QTBAG1ACB acts as a central hub for signal management, aggregating inputs from pulse rate sensors, megawatt transducers, and vibration monitoring devices before routing them to the TC QC board for processing1. This board also supports the connection of the Terminal Interface Monitor (TIM N), enabling real-time system diagnostics and maintenance. A key differentiator is its bypass relay mechanism, which safeguards Corebus communications during power loss, ensuring uninterrupted operation1. By consolidating signal pathways and enhancing communication resilience, the GE DS200QTBAG1ACB reduces complexity and minimizes downtime, making it a cornerstone of GE’s turbine control architecture.

Engineered for compatibility with the Mark V series, the GE DS200QTBAG1ACB exemplifies GE’s commitment to backward compatibility and long-term system support. Its role in maintaining signal integrity and system stability positions it as a strategic component for retrofitting or upgrading aging infrastructure. With a focus on durability and precision, this termination board is ideal for industries where legacy systems must operate efficiently alongside modern automation demands.

Technical Specifications

| Parameter | Value |

|---|---|

| Manufacturer | General Electric (GE) |

| Product Type | RST Termination Board |

| Series | Speedtronic Mark V |

| Physical Dimensions | Depth: 127.5 mm, Height: 186 mm, Width: 59 mm |

| Weight | 0.7 kg |

| Terminal Configuration | 2 terminal blocks with 77 terminals each, 15 jumpers, 3 x 34-pin connectors, 3 x 16-pin connectors13 |

| Signal Management | Supports analog and digital signals for turbine control and monitoring |

| Power Loss Protection | Bypass relay ensures Corebus communication continuity during outages1 |

| Operating Environment | -20°C to 70°C, 5–95% humidity (non-condensing) |

| Installation | Rack-mounted within Mark V control panels |

Main Features and Advantages

The GE DS200QTBAG1ACB stands out for its high-density signal integration, consolidating inputs from multiple sensors into a single, organized interface. This reduces cabling complexity and streamlines system maintenance, as each terminal block is clearly labeled for easy identification (e.g., TB1-66 for terminal 66 on block 1)3. The board’s 15 configurable jumpers allow for flexible signal conditioning, such as adjusting burden resistors for pressure transducers or configuring analog input ranges3. This adaptability makes it suitable for diverse applications, from simple monitoring to complex turbine control scenarios.

Reliability is a hallmark of the GE DS200QTBAG1ACB, with its bypass relay feature ensuring uninterrupted Corebus communication during power fluctuations. This redundancy minimizes the risk of system failures, a critical advantage in industries like power generation where downtime translates to significant financial losses. Additionally, the board’s robust construction and wide operating temperature range (-20°C to 70°C) ensure consistent performance in harsh industrial environments1.

Maintenance is simplified through the GE DS200QTBAG1ACB’s modular design. Terminals are easily accessible, and the board’s documentation provides detailed pinout diagrams, enabling quick replacement without specialized training. For diagnostic purposes, the Mark V system’s built-in tools (accessed via the control panel) generate comprehensive reports, aiding in troubleshooting and reducing mean time to repair (MTTR)3.

Application Fields

The GE DS200QTBAG1ACB is purpose-built for gas turbine control systems, where it plays a pivotal role in managing critical signals related to speed, load, and safety. In power plants, it ensures precise synchronization between turbines and the grid, optimizing energy output while protecting against overspeed events. In oil and gas facilities, the board supports real-time monitoring of compressor discharge pressures and vibration levels, preventing equipment damage and ensuring compliance with safety standards.

Beyond turbines, the GE DS200QTBAG1ACB finds utility in industrial process control environments requiring reliable signal management. For example, it can interface with steam turbine control systems to regulate steam flow and maintain operational efficiency. Its compatibility with the Mark V series also makes it a preferred choice for retrofitting older systems, extending their lifespan while integrating with modern automation protocols.

Related Products

- GE DS200TBQBG1ACB: An analog I/O termination board for the Mark V system, designed for monitoring vibration transducers and pressure inputs. It shares the same terminal block configuration as the DS200QTBAG1ACB but focuses on analog signal conditioning314.

- GE DS200SDCCG4AHD: A drive control card that works in tandem with the DS200QTBAG1ACB to manage turbine speed and torque, ensuring seamless coordination between control and power modules9.

- GE DS200TCQBG1BCA: A trip board that interfaces with the DS200QTBAG1ACB to execute emergency shutdowns, enhancing system safety in critical applications6.

- GE IS200DAMEG1A: A gate drive amplifier card for Mark VI systems, offering similar signal conditioning capabilities but optimized for newer turbine control architectures5.

- GE DS200PTBAG1AEC: A termination board for the Mark V’s independent protection module, complementing the DS200QTBAG1ACB in redundant control setups13.

Installation and Maintenance

Pre-installation preparations:

Before installing the GE DS200QTBAG1ACB, verify compatibility with the Mark V system’s rack dimensions and power requirements. Use masking tape to label signal wires with their terminal IDs (e.g., TB1-66) to ensure correct reconnection. Inspect the board for physical damage and electrostatic discharge (ESD) protection, as sensitive components may be compromised by improper handling320.

Before installing the GE DS200QTBAG1ACB, verify compatibility with the Mark V system’s rack dimensions and power requirements. Use masking tape to label signal wires with their terminal IDs (e.g., TB1-66) to ensure correct reconnection. Inspect the board for physical damage and electrostatic discharge (ESD) protection, as sensitive components may be compromised by improper handling320.

Maintenance suggestions:

Regularly clean the board to prevent dust accumulation, which can affect signal integrity. Check terminal connections for looseness and retighten as needed, following torque specifications provided in the user manual. Monitor the system’s diagnostic reports to identify potential issues, such as 异常信号波动或连接器故障. For firmware updates or complex troubleshooting, consult GE’s official documentation or certified technicians to avoid configuration errors320.

Regularly clean the board to prevent dust accumulation, which can affect signal integrity. Check terminal connections for looseness and retighten as needed, following torque specifications provided in the user manual. Monitor the system’s diagnostic reports to identify potential issues, such as 异常信号波动或连接器故障. For firmware updates or complex troubleshooting, consult GE’s official documentation or certified technicians to avoid configuration errors320.

Product Guarantee

Our company, a leading industrial control parts distributor with 17 years of expertise, offers a 1-year quality warranty for the GE DS200QTBAG1ACB. This warranty covers hardware malfunctions unrelated to improper use or environmental damage. In the event of defects, we provide prompt replacement services to minimize downtime. For discontinued models or urgent orders, our global supply chain network ensures rapid fulfillment of scarce parts, supported by 24/7 technical assistance. We stand behind the reliability of the GE DS200QTBAG1ACB and are committed to delivering solutions that keep your industrial systems running efficiently.

For inquiries or quotes, contact us via WhatsApp: +86 18859254943 or email sales@ygdcs.com.

Note: All technical details are derived from verified sources and GE’s official documentation. The GE DS200QTBAG1ACB is a genuine GE product, and our company is an authorized distributor, ensuring authenticity and compliance with industry standards.

中文版

中文版