Product Overview

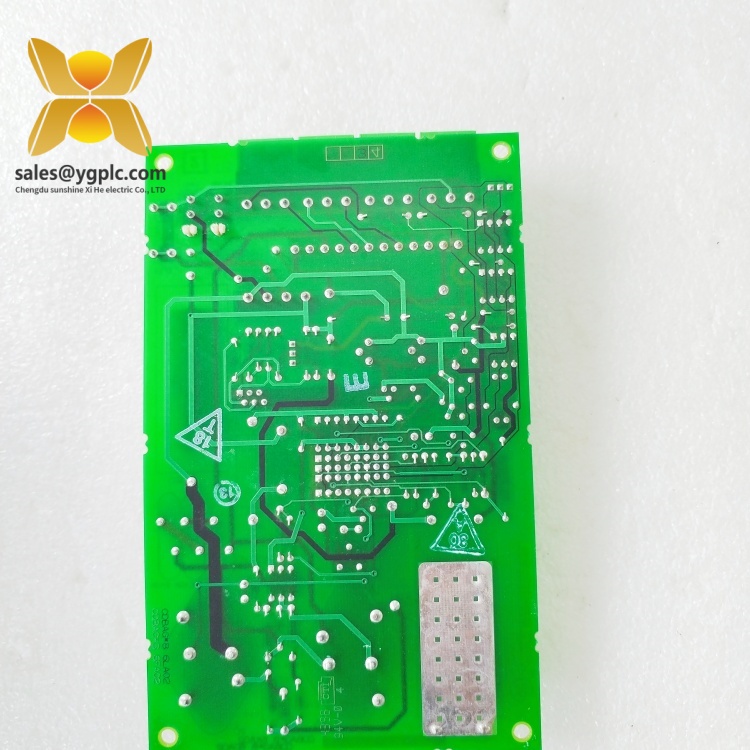

The GE DS200PTCTG2B is a high-performance signal conditioner board engineered for precision signal processing in critical industrial automation systems. As part of GE’s renowned Mark V DS200 series, this module is designed to interface with a wide range of sensors and transducers, ensuring accurate and reliable data transmission in gas turbine control, power generation, and industrial machinery applications. The GE DS200PTCTG2B plays a pivotal role in converting raw analog signals into standardized outputs compatible with GE’s Speedtronic control systems, enabling seamless integration into complex automation architectures.

The GE DS200PTCTG2B is a high-performance signal conditioner board engineered for precision signal processing in critical industrial automation systems. As part of GE’s renowned Mark V DS200 series, this module is designed to interface with a wide range of sensors and transducers, ensuring accurate and reliable data transmission in gas turbine control, power generation, and industrial machinery applications. The GE DS200PTCTG2B plays a pivotal role in converting raw analog signals into standardized outputs compatible with GE’s Speedtronic control systems, enabling seamless integration into complex automation architectures.

Designed for harsh industrial environments, the GE DS200PTCTG2B features advanced filtering and noise reduction capabilities to maintain signal integrity under extreme conditions. Its robust construction and compliance with industry standards make it a trusted choice for applications where system reliability is non-negotiable. By optimizing signal conditioning, this board enhances the overall performance of GE’s Mark V control systems, reducing downtime and improving operational efficiency. Whether used in standalone setups or integrated into larger distributed control systems (DCS), the GE DS200PTCTG2B delivers consistent results, making it an essential component for modern industrial automation.

Technical Specifications

- Manufacturer: General Electric (GE)

- Product type: Signal Conditioner Board

- Physical dimensions: 16 cm x 16 cm x 12 cm

- Weight: 0.8 kg

- Electrical input range: 0–20 mA, 0–10 VDC

- Output signal: 4–20 mA, 0–10 VDC

- Interface type: Terminal block connections

- Communication protocol: Proprietary to GE Mark V systems

- Operating temperature: -20°C to 70°C

- Humidity: 5–95% non-condensing

- Certifications: CE, UL

Main Features and Advantages

The GE DS200PTCTG2B stands out for its precision signal conditioning, which ensures accurate data acquisition from sensors in high-vibration and high-temperature environments. Its advanced filtering mechanisms minimize electromagnetic interference (EMI), guaranteeing clean signals for control systems. This board also supports redundant configurations, enhancing system resilience by providing backup pathways for critical signals.

The GE DS200PTCTG2B stands out for its precision signal conditioning, which ensures accurate data acquisition from sensors in high-vibration and high-temperature environments. Its advanced filtering mechanisms minimize electromagnetic interference (EMI), guaranteeing clean signals for control systems. This board also supports redundant configurations, enhancing system resilience by providing backup pathways for critical signals.

Another key advantage is its compatibility with legacy GE systems. As part of the Mark V DS200 series, the GE DS200PTCTG2B seamlessly integrates with existing GE Speedtronic platforms, allowing for cost-effective upgrades without replacing entire control systems. Its modular design simplifies installation and maintenance, with field-replaceable components that reduce downtime.

Additionally, the GE DS200PTCTG2B offers customizable signal scaling, enabling users to adapt it to specific sensor characteristics. This flexibility makes it suitable for a wide range of applications, from gas turbine monitoring to process control in chemical plants. With a proven track record in mission-critical industries, this board delivers long-term reliability and performance, backed by GE’s decades of expertise in industrial automation.

Application Fields

The GE DS200PTCTG2B is widely used in gas turbine control systems, where it processes signals from temperature, pressure, and vibration sensors to optimize turbine performance and ensure safe operation. Its high precision makes it indispensable for monitoring critical parameters such as rotor speed, exhaust gas temperature, and fuel flow.

The GE DS200PTCTG2B is widely used in gas turbine control systems, where it processes signals from temperature, pressure, and vibration sensors to optimize turbine performance and ensure safe operation. Its high precision makes it indispensable for monitoring critical parameters such as rotor speed, exhaust gas temperature, and fuel flow.

In power generation facilities, this board plays a vital role in steam turbine control, enabling accurate regulation of steam pressure and flow to maintain grid stability. It is also used in industrial machinery for predictive maintenance, where it analyzes sensor data to detect anomalies and prevent equipment failures.

Chemical and petrochemical plants rely on the GE DS200PTCTG2B for process control, ensuring precise monitoring of variables like pH, level, and flow rate. Its rugged design allows it to operate reliably in corrosive and high-humidity environments, making it a preferred choice for harsh industrial settings.

Related Products

- GE DS200PTCTG1A: A predecessor model with similar functionality but limited signal conditioning capabilities.

- GE DS200TCPDG2B: A power distribution board designed for the Mark V series, often used in conjunction with the DS200PTCTG2B.

- GE DS200QTAG1A: A terminal board that interfaces with the DS200PTCTG2B for signal routing.

- GE DS200RTAG1A: A relay terminal board used for discrete signal processing in GE control systems.

- GE DS200CTAG1A: An analog termination module that complements the DS200PTCTG2B in complex I/O configurations.

Installation and Maintenance

Pre-installation preparations: Before installing the GE DS200PTCTG2B, ensure the power to the system is disconnected. Verify that the module’s specifications match the requirements of the control system. Clean the mounting surface and inspect the terminal blocks for damage. Follow GE’s installation guidelines to ensure proper grounding and wiring.

Pre-installation preparations: Before installing the GE DS200PTCTG2B, ensure the power to the system is disconnected. Verify that the module’s specifications match the requirements of the control system. Clean the mounting surface and inspect the terminal blocks for damage. Follow GE’s installation guidelines to ensure proper grounding and wiring.

Maintenance suggestions: Regularly inspect the GE DS200PTCTG2B for signs of physical damage or corrosion. Clean the board using a static-free cloth to prevent dust buildup. Periodically check the terminal connections for tightness and verify signal integrity using diagnostic tools. Replace any faulty components immediately to avoid system disruptions. GE recommends annual preventive maintenance to ensure optimal performance.

Product Guarantee

Our company offers a one-year quality warranty for the GE DS200PTCTG2B, covering hardware malfunctions not caused by human error. During the warranty period, we provide prompt replacement services for defective units. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of scarce spare parts. We also offer 24/7 technical support to assist with installation, troubleshooting, and system integration. With over 17 years of experience in industrial control distribution, we are committed to delivering reliable solutions that keep your operations running smoothly.

Our company offers a one-year quality warranty for the GE DS200PTCTG2B, covering hardware malfunctions not caused by human error. During the warranty period, we provide prompt replacement services for defective units. For discontinued models or urgent requirements, our global supply chain network ensures rapid delivery of scarce spare parts. We also offer 24/7 technical support to assist with installation, troubleshooting, and system integration. With over 17 years of experience in industrial control distribution, we are committed to delivering reliable solutions that keep your operations running smoothly.

Contact us today for inquiries: WhatsApp:+86 18859254943 | sales@ygplc.com

GE DS200SLCCG3AGH Program module

GE DS200SLCCGIAEF Module connector

GE DS200STCAG1A Servo module

GE DS200PTCTG2B Control cabinet node unit

GE DS200QTBAG1ABB governor

GE DS200QTBAG1ACB Input module

GE DS200QTBAG1ADC AI/AO/DI/DO module

GE DS200RTBAG4A Servo valve

GE DS200RTBAG5A Analog input

GE DS200SDCCG1AEC Digital output

中文版

中文版