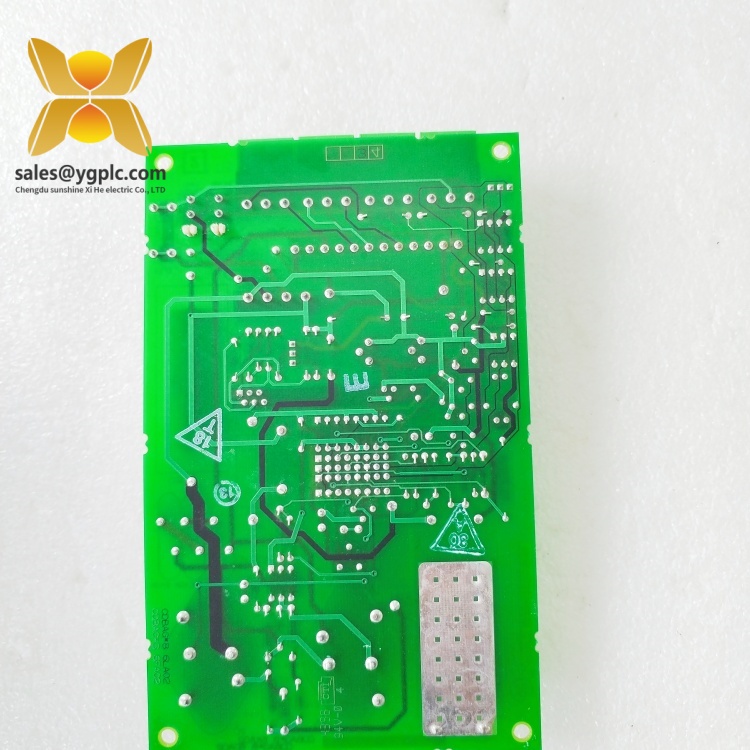

GE DS200PTCTG1B RTD/Thermocouple Input Module

Product Overview

The GE DS200PTCTG1B is a high-precision RTD/Thermocouple Input Module engineered for GE’s Mark VIe control system, a leading platform in industrial automation. Designed to convert temperature signals from resistance temperature detectors (RTDs) and thermocouples into digital data, this module delivers critical temperature monitoring for applications in power generation, oil & gas, and manufacturing. As part of the DS200 Series, the DS200PTCTG1B ensures reliable operation in harsh environments, providing real-time temperature data for process control, equipment protection, and predictive maintenance.

Featuring 16 isolated input channels, the GE DS200PTCTG1B supports multiple sensor types, including Pt100 RTDs and J/K/T-type thermocouples, with configurable ranges to accommodate diverse industrial applications. Its advanced signal conditioning includes cold-junction compensation for thermocouples and digital filtering to reject electrical noise, ensuring measurement accuracy within ±0.1°C. The module’s hot-swappable design allows for maintenance without system shutdowns, minimizing downtime in critical operations.

In automation ecosystems, the DS200PTCTG1B interfaces with the Mark VIe controller via a high-speed serial bus, enabling seamless integration with other modules such as analog outputs and communication gateways. Its compatibility with GE’s Proficy software suite facilitates configuration, diagnostics, and trending, enhancing operational visibility and control. By providing precise temperature data, the module supports safety-critical applications like turbine overheat protection and reactor temperature regulation, making it indispensable for industries reliant on accurate thermal management.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200PTCTG1B |

| Manufacturer | GE |

| Product Type | RTD/Thermocouple Input Module |

| Platform | Mark VIe |

| Input Channels | 16 isolated channels |

| Sensor Types | Pt100 RTD, J/K/T-type thermocouples |

| Resolution | 16-bit |

| Accuracy | ±0.1°C (RTD), ±1°C (thermocouple) |

| Isolation | 500 V RMS channel-to-channel, 1500 V RMS channel-to-chassis |

| Cold-Junction Compensation | Automatic, ±0.5°C accuracy |

| Power Supply | 24 V DC ±10% (from Mark VIe rack) |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.7 kg |

| Operating Temperature | -40°C to +85°C |

| EMC Compliance | IEC 61131-2, EN 61000-6-2/6-4 |

Key Features and Advantages

Multi-Sensor Compatibility: The DS200PTCTG1B supports both RTDs and thermocouples, eliminating the need for separate modules and simplifying system design. This flexibility reduces hardware costs and streamlines inventory management for facilities using diverse temperature sensors.

High Precision and Noise Immunity: With 16-bit resolution and advanced digital filtering, the module delivers accurate temperature measurements even in electrically noisy environments. Its galvanic isolation prevents ground loops, ensuring signal integrity in industrial settings with high electromagnetic interference.

Automatic Cold-Junction Compensation: For thermocouple inputs, the module provides built-in cold-junction compensation, eliminating the need for external compensation devices and ensuring consistent accuracy across temperature ranges.

Hot-Swap Capability: Designed for continuous operation, the DS200PTCTG1B can be replaced without shutting down the system, minimizing downtime during maintenance or sensor replacement. This feature is critical for 24/7 industrial processes where interruptions are costly.

Comprehensive Diagnostics: The module continuously monitors sensor health, detecting open circuits, short circuits, and out-of-range values. Diagnostic data is transmitted to the Mark VIe controller, enabling proactive maintenance and reducing the risk of unplanned shutdowns.

Rugged Industrial Design: Built to withstand harsh conditions, the DS200PTCTG1B meets rigorous standards for vibration, shock, and temperature extremes, ensuring reliable performance in demanding environments such as power plants and refineries.

Application Areas

The GE DS200PTCTG1B is essential for temperature-critical applications across industries:

- Power Generation: Monitors turbine bearing temperatures, generator stator windings, and boiler feedwater in thermal and nuclear power plants, ensuring safe and efficient operation.

- Oil & Gas: Measures temperature in pipelines, reactors, and distillation columns, supporting process control and preventing overheating in refining and petrochemical facilities.

- Manufacturing: Controls oven and furnace temperatures in metal processing, glass manufacturing, and food production, ensuring product quality and compliance with safety standards.

- Chemical Processing: Monitors exothermic reactions in reactors, preventing runaway reactions and ensuring process stability in chemical manufacturing.

Specific applications include:

- Turbine Protection: Integrates with RTDs to monitor bearing temperatures, triggering alarms or shutdowns if thresholds are exceeded, protecting against catastrophic failure.

- Process Optimization: Uses thermocouple inputs to regulate heating and cooling processes, maintaining precise temperature control for consistent product quality.

- Environmental Monitoring: Measures temperature in HVAC systems and environmental chambers, ensuring optimal conditions for personnel comfort and equipment reliability.

Related Products

- DS200AAHAH2ADC (Analog Input Module): Complements the DS200PTCTG1B by providing additional analog input channels for non-temperature sensors, such as pressure or flow transmitters.

- DS200AASA (Analog Output Module): Works in tandem with the DS200PTCTG1B to control heating or cooling equipment based on temperature measurements, forming a closed-loop control system.

- DS200TCTGG1A (Turbine Control Module): Processes temperature data from the DS200PTCTG1B to manage turbine operations, ensuring safe and efficient power generation.

- DS200TBCH (Terminal Block Module): Provides a convenient interface for connecting RTDs and thermocouples to the DS200PTCTG1B, simplifying wiring and maintenance.

- DS200COMM (Communication Module): Enables remote access to temperature data via Ethernet or serial interfaces, facilitating integration with SCADA systems or cloud-based monitoring platforms.

- DS200PWR (Power Supply Module): Ensures reliable power delivery to the DS200PTCTG1B and other Mark VIe modules, supporting redundant configurations for critical applications.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE DS200PTCTG1B, verify that the Mark VIe rack is properly grounded and powered. Configure the module using GE’s Proficy software, setting sensor types, ranges, and filtering parameters. Use shielded, twisted-pair cables to connect sensors, routing them away from high-voltage sources to minimize interference. Ensure proper cable terminations to prevent signal loss or noise ingress.

Before installing the GE DS200PTCTG1B, verify that the Mark VIe rack is properly grounded and powered. Configure the module using GE’s Proficy software, setting sensor types, ranges, and filtering parameters. Use shielded, twisted-pair cables to connect sensors, routing them away from high-voltage sources to minimize interference. Ensure proper cable terminations to prevent signal loss or noise ingress.

Maintenance Suggestions:

- Routine Inspections: Monthly checks of LED indicators and diagnostic data via Proficy software to identify any sensor or module faults. Inspect terminal connections for tightness and corrosion, especially in high-humidity environments.

- Calibration: Annually calibrate the module using a certified temperature source, comparing measured values against known standards. Adjust offsets or gains as needed to maintain accuracy.

- Firmware Updates: Periodically update the module’s firmware to incorporate bug fixes and new features, following GE’s recommended procedures to ensure compatibility and reliability.

- Spare Parts Management: Store spare DS200PTCTG1B modules in a controlled environment to prevent damage from static electricity or moisture. Rotate inventory to ensure readiness for emergency replacements.

Product Guarantee

Our company provides a 12-month quality warranty for the GE DS200PTCTG1B, covering hardware defects under normal use. In the event of failure, we offer prompt replacement services to minimize downtime. For legacy models like the DS200PTCTG1B, our global supply chain excels at sourcing rare components, ensuring quick availability for urgent needs. Our technical support team is available 24/7 to assist with installation, configuration, and troubleshooting, providing expertise to maintain your system’s reliability.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE DS200PTBAG1ADC Control panel

GE DS200PTBAG1AEC Double output

GE DS200PTBAG1BAA Expansion module

GE DS200PTBAGIBBA RXM rack

GE DS200PTCTG1B Thermoelectric couple

GE DS200PTCTG2B Double-action switch

GE DS200QTBAG1ABB DC/DC

GE DS200QTBAG1ACB Analog output module

GE DS200QTBAG1ADC display

GE DS200RTBAG4A Relay output

GE DS200RTBAG5A Optical isolation module

GE DS200SDCCG1AEC transformer

GE DS200SHVG1BGD Digital output module

GE DS200SHVIG1BHD Control system power supply

中文版

中文版