GE DS200PTBAGIBBA Protection Termination Board

Product Overview

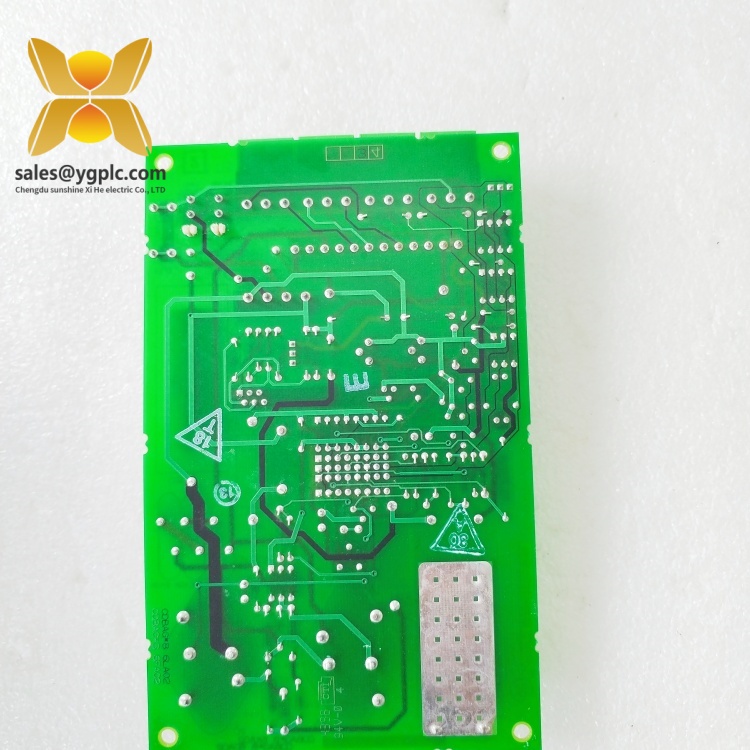

The GE DS200PTBAGIBBA is a high-performance protection termination board engineered for critical industrial automation systems, specifically within GE’s Speedtronic Mark V turbine control platform. Designed to interface with analog and digital signals in gas and steam turbine applications, this module serves as a vital component for signal conditioning, termination, and transmission, ensuring precise control and protection of turbine operations. As part of the Mark V series, the GE DS200PTBAGIBBA is renowned for its rugged reliability, compatibility with legacy systems, and advanced diagnostic capabilities, making it a preferred choice for industries where downtime is costly and safety is paramount.

The GE DS200PTBAGIBBA is a high-performance protection termination board engineered for critical industrial automation systems, specifically within GE’s Speedtronic Mark V turbine control platform. Designed to interface with analog and digital signals in gas and steam turbine applications, this module serves as a vital component for signal conditioning, termination, and transmission, ensuring precise control and protection of turbine operations. As part of the Mark V series, the GE DS200PTBAGIBBA is renowned for its rugged reliability, compatibility with legacy systems, and advanced diagnostic capabilities, making it a preferred choice for industries where downtime is costly and safety is paramount.

Integrated into the Mark V control system, the GE DS200PTBAGIBBA terminates signals from sensors, switches, and other field devices, routing them to the system’s control cores for processing. Its dual terminal blocks with 72 signal wires each and multiple 10-pin connectors (e.g., JJR, JM, JN) enable seamless integration with components like flame detectors, speed pickups, and generator voltage/current sensors13. By consolidating these inputs, the module enhances system efficiency and reduces wiring complexity, while built-in redundancy and fault isolation features safeguard against operational disruptions.

The GE DS200PTBAGIBBA excels in environments requiring high-speed data handling and real-time response, such as power generation, oil and gas, and industrial manufacturing. Its design prioritizes ease of maintenance, with removable connectors and clear labeling for quick troubleshooting, minimizing downtime during repairs. As a discontinued yet widely used model, its availability through specialized suppliers ensures continued support for legacy installations, providing long-term value to industries reliant on GE’s turbine control infrastructure. 薛

薛

薛

薛Technical Specifications

- Manufacturer: General Electric (GE)

- Product Type: Protection Termination Board

- Series: Speedtronic Mark V

- Physical Dimensions: 16 cm (width) × 16 cm (height) × 12 cm (depth)5

- Weight: 0.8 kg5

- Origin: United States

- Interface Type: 2 terminal blocks (72 wires each), 3 × 10-pin connectors (JJR, JM, JN), terminal posts for 6 signal wires314

- Communication Protocol: Serial (RS-232/485) and Ethernet for diagnostics7

- Working Environment: -20°C to 60°C, humidity up to 95% non-condensing, vibration resistance up to 5g4

- Installation: Rack-mounted with screw terminals; requires ESD-safe handling19

Main Features and Advantages

The GE DS200PTBAGIBBA stands out for its robust signal management and reliability. Its dual terminal blocks and multiple connectors allow for simultaneous termination of diverse inputs, including overspeed sensors, flame detection signals, and generator parameters, ensuring accurate data transmission to the control system314. The module’s diagnostic capabilities—such as LED indicators for power status and signal integrity—enable quick identification of faults, reducing maintenance time and costs.

The GE DS200PTBAGIBBA stands out for its robust signal management and reliability. Its dual terminal blocks and multiple connectors allow for simultaneous termination of diverse inputs, including overspeed sensors, flame detection signals, and generator parameters, ensuring accurate data transmission to the control system314. The module’s diagnostic capabilities—such as LED indicators for power status and signal integrity—enable quick identification of faults, reducing maintenance time and costs.

Another key strength is its compatibility with legacy systems. As part of the Mark V series, the GE DS200PTBAGIBBA seamlessly integrates with older GE turbine control platforms, offering a cost-effective solution for retrofitting or maintaining aging infrastructure. Its hardware jumper configuration (e.g., J1 for audible alarm control) allows for field-adjustable settings, enhancing flexibility in varied operational scenarios9.

The module’s rugged construction ensures durability in harsh industrial environments, with a PCB coating that resists moisture, dust, and corrosion22. This, combined with its redundant design, minimizes the risk of failure and supports continuous operation in high-stakes applications like power plants and petrochemical facilities.

Application Fields

The GE DS200PTBAGIBBA is widely deployed in industrial turbine control systems, particularly in:

The GE DS200PTBAGIBBA is widely deployed in industrial turbine control systems, particularly in:

- Power Generation: Monitoring steam and gas turbines to ensure stable energy production and grid synchronization.

- Oil and Gas: Managing compressor and pump turbines in upstream and downstream operations, ensuring safe and efficient processes.

- Manufacturing: Controlling large machinery in sectors like steel production and cement manufacturing, where precise speed and load regulation are critical.

Its ability to interface with diverse sensors and actuators makes it ideal for applications requiring real-time data processing and safety-critical control. For example, in turbine overspeed protection, the module processes speed sensor inputs and triggers emergency shutdowns if thresholds are exceeded, preventing catastrophic damage914.

Related Products

- GE DS200PTBAG1B: A predecessor model with similar functionality but fewer revisions, suitable for older Mark V systems19.

- GE DS200TCPDG1BBA: A LAN communication card for Mark V systems, complementing the DS200PTBAGIBBA in distributed control setups6.

- GE DS200TBPAG1A: A communication module supporting serial protocols, enhancing connectivity for remote monitoring7.

- GE DS200PTBAG1ABA: A newer revision with improved diagnostic features, offering backward compatibility with the DS200PTBAGIBBA28.

- GE DS200ACNAG1ADD: A Genius adapter module for integrating the Mark V system with modern industrial networks22.

Installation and Maintenance

Pre-installation preparations:

Before installing the GE DS200PTBAGIBBA, ensure the power to the system is disconnected and proper ESD precautions are taken (e.g., wearing anti-static gloves)19. Map the signal wires from the old board to the new one, labeling terminals to avoid misconnections. Verify the module’s compatibility with the existing Mark V system configuration and inspect for physical damage.

Pre-installation preparations:

Before installing the GE DS200PTBAGIBBA, ensure the power to the system is disconnected and proper ESD precautions are taken (e.g., wearing anti-static gloves)19. Map the signal wires from the old board to the new one, labeling terminals to avoid misconnections. Verify the module’s compatibility with the existing Mark V system configuration and inspect for physical damage.

Maintenance suggestions:

Regular maintenance includes cleaning the board to prevent dust accumulation and checking connectors for loose wires. Periodically test the module’s diagnostic functions, such as LED indicators and self-tests, to ensure optimal performance. For repairs, consult certified technicians familiar with GE’s Mark V series, as replacement components must meet OEM standards14.

Regular maintenance includes cleaning the board to prevent dust accumulation and checking connectors for loose wires. Periodically test the module’s diagnostic functions, such as LED indicators and self-tests, to ensure optimal performance. For repairs, consult certified technicians familiar with GE’s Mark V series, as replacement components must meet OEM standards14.

Product Guarantee

Our company offers a one-year quality warranty for the GE DS200PTBAGIBBA, covering hardware malfunctions unrelated to misuse or environmental damage. During the warranty period, we provide prompt replacement services for defective units. For discontinued models like this, our global supply chain network ensures rapid availability of scarce spare parts, supporting urgent repair needs and minimizing downtime. We also offer technical support to assist with installation, troubleshooting, and system integration, ensuring seamless operation of your industrial control infrastructure.

Our company offers a one-year quality warranty for the GE DS200PTBAGIBBA, covering hardware malfunctions unrelated to misuse or environmental damage. During the warranty period, we provide prompt replacement services for defective units. For discontinued models like this, our global supply chain network ensures rapid availability of scarce spare parts, supporting urgent repair needs and minimizing downtime. We also offer technical support to assist with installation, troubleshooting, and system integration, ensuring seamless operation of your industrial control infrastructure.

Contact us via WhatsApp or email at sales@ygplc.com for pricing, availability, or technical inquiries.

GE DS200SDCCG5A AI/AO/DI/DO module

GE DS200TBCBGIAAA Servo valve

GE DS200TBOFG1A Analog input

GE DS200TBPAG1A Control cabinet node unit

GE DS200PANAHIADS3820NGDB governor

GE DS200QTBAG1ACB Input module

GE DS200SHVMGIA AI/AO/DI/DO module

GE DS200SLCCG1ABB Connecting module

GE DS200PTCTG1B driver

GE DS200PTCTG2B servo

GE DS200TBCBGIAAA Servo valve

GE DS200TBOFG1A Analog input

GE DS200TBPAG1A Control cabinet node unit

GE DS200PANAHIADS3820NGDB governor

GE DS200QTBAG1ACB Input module

GE DS200SHVMGIA AI/AO/DI/DO module

GE DS200SLCCG1ABB Connecting module

GE DS200PTCTG1B driver

GE DS200PTCTG2B servo

中文版

中文版