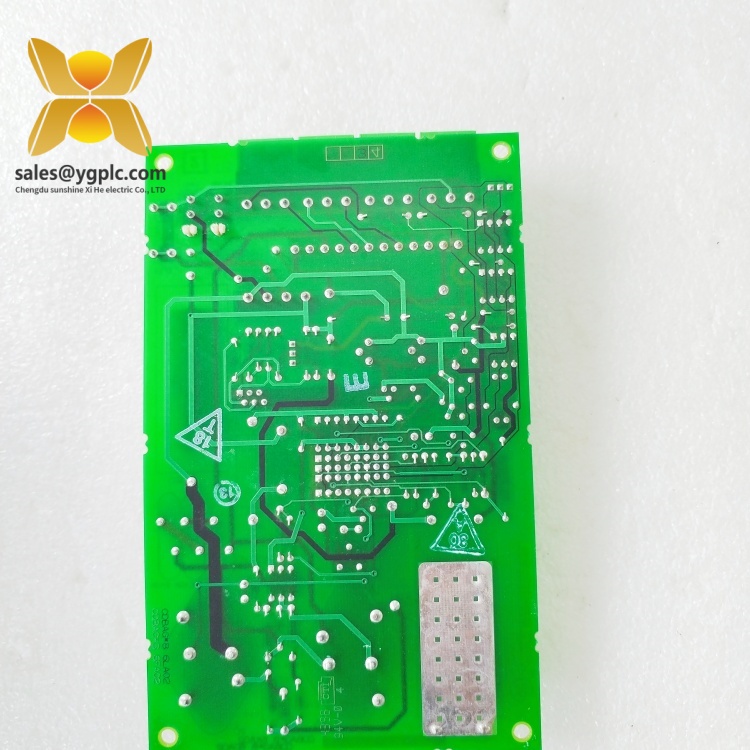

GE DS200PTBAG1BAA Mark VIe Power Supply Module

Product Overview

The GE DS200PTBAG1BAA is a critical Power Supply Module designed for GE’s Mark VIe distributed control system (DCS), providing redundant and regulated power to automation systems in industrial environments. Engineered to deliver reliable 24V DC power to Mark VIe racks, this module ensures continuous operation of control and I/O modules, making it indispensable for applications where downtime could lead to safety risks or significant financial losses. As part of the DS200 Series, the DS200PTBAG1BAA integrates seamlessly with other Mark VIe components, supporting mission-critical processes in power generation, oil & gas, and manufacturing sectors.

The GE DS200PTBAG1BAA features dual redundant inputs with automatic failover, ensuring uninterrupted power delivery even if one input source fails. Its high-efficiency design (up to 90%) minimizes heat generation, reducing the need for additional cooling and enhancing long-term reliability. The module includes comprehensive protection mechanisms against overvoltage, undervoltage, and short circuits, safeguarding connected components from electrical faults. Built-in LED indicators provide real-time status monitoring, allowing operators to quickly identify power supply health and potential issues.

In automation ecosystems, the DS200PTBAG1BAA serves as the backbone of the Mark VIe system, delivering clean, stable power to processors, I/O modules, and communication interfaces. Its hot-swappable design enables maintenance or replacement without disrupting system operation, a critical feature for 24/7 industrial processes. By ensuring consistent power delivery, this module enhances the overall reliability of the control system, supporting precise regulation of turbines, compressors, and other industrial equipment.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200PTBAG1BAA |

| Manufacturer | GE |

| Product Type | Power Supply Module |

| Input Voltage | 100–240 V AC, 50/60 Hz (dual redundant inputs) |

| Output Voltage | 24 V DC ±5% |

| Output Power | 250 W (max) per module |

| Efficiency | Up to 90% |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 2.3 kg |

| Operating Temperature | -40°C to +70°C |

| Humidity | 0–95% non-condensing |

| EMC Compliance | EN 61000-6-2, EN 61000-6-4 |

| Mounting | Rack-mounted in Mark VIe enclosure |

Key Features and Advantages

Redundant Power Paths: The DS200PTBAG1BAA supports dual AC inputs with automatic failover, eliminating single points of failure and ensuring continuous operation during power source disruptions. This redundancy is critical for safety-critical applications where power loss could lead to system shutdowns or equipment damage.

High Efficiency and Thermal Management: With up to 90% efficiency, the module minimizes energy waste and heat generation, reducing the load on cooling systems and extending component lifespan. Its robust thermal design allows operation in high-temperature environments without derating.

Comprehensive Protection: Built-in overvoltage, undervoltage, and short-circuit protection safeguards both the power supply and connected modules from electrical faults, enhancing system reliability and reducing maintenance costs.

Real-Time Monitoring: LED indicators provide instant visual feedback on power status, input/output voltages, and fault conditions, enabling quick diagnosis and minimizing downtime during troubleshooting.

Hot-Swappable Design: The module can be replaced while the system is operational, allowing for maintenance or upgrades without disrupting critical processes. This feature reduces downtime and supports continuous industrial operations.

Compatibility and Scalability: Designed specifically for the Mark VIe platform, the DS200PTBAG1BAA seamlessly integrates with other GE control modules, supporting scalable configurations from small to large industrial systems.

Application Areas

The GE DS200PTBAG1BAA is essential for powering critical control systems in various industries:

- Power Generation: Ensures reliable operation of turbine control systems, boiler management, and generator protection in thermal, hydroelectric, and renewable energy plants, where uninterrupted power is vital for grid stability.

- Oil & Gas: Powers safety systems, wellhead control, and pipeline monitoring in upstream, midstream, and downstream operations, supporting continuous production and compliance with safety regulations.

- Manufacturing: Provides stable power to automation systems in automotive, chemical, and pharmaceutical plants, ensuring consistent production quality and preventing costly downtime.

- Water/Wastewater Treatment: Supports control systems for pumps, valves, and filtration processes, maintaining continuous operation of essential infrastructure.

Specific applications include:

- Turbine Control: Powers the Mark VIe controllers that regulate steam and gas turbines, ensuring precise speed and load control for efficient power generation.

- Emergency Shutdown Systems (ESD): Provides backup power to safety-critical ESD systems, ensuring they remain operational during power outages to prevent hazardous events.

- Process Automation: Supplies power to I/O modules and communication gateways in DCS systems, enabling real-time monitoring and control of industrial processes.

Related Products

- DS200PTBBG1A (Power Supply Module): A similar power supply module for Mark VIe systems with different input voltage ranges, offering flexibility for global applications.

- DS200PTBCG1A (Power Supply Module): An upgraded version with higher output power capacity, suitable for larger control systems with increased power demands.

- DS200PTBDG1A (Power Supply Module): A redundant power supply module designed for parallel operation with the DS200PTBAG1BAA to provide additional power capacity and fault tolerance.

- DS200VJICG1A (Mark VIe Controller): Works in conjunction with the DS200PTBAG1BAA to process control logic and manage I/O modules in the Mark VIe system.

- DS200TCTGG1A (Turbine Control Module): Utilizes power from the DS200PTBAG1BAA to monitor and control turbine operations in power generation applications.

- DS200AAHAH2ADC (Analog Input Module): Connects to the Mark VIe system powered by the DS200PTBAG1BAA, converting analog signals from sensors into digital data for processing.

- DS200TBCH (Terminal Block Module): Provides a connection interface for field devices in the Mark VIe system, powered by the DS200PTBAG1BAA.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE DS200PTBAG1BAA, ensure the Mark VIe rack is properly grounded and the power sources are disconnected. Verify the input voltage requirements match the available power supply. Inspect the module for physical damage and clean the mounting area to prevent debris interference. Use appropriate tools to secure the module in the rack, ensuring proper alignment with power connectors. Connect the dual AC inputs to separate, independent power sources to maintain redundancy.

Before installing the GE DS200PTBAG1BAA, ensure the Mark VIe rack is properly grounded and the power sources are disconnected. Verify the input voltage requirements match the available power supply. Inspect the module for physical damage and clean the mounting area to prevent debris interference. Use appropriate tools to secure the module in the rack, ensuring proper alignment with power connectors. Connect the dual AC inputs to separate, independent power sources to maintain redundancy.

Maintenance Suggestions:

- Routine Inspections: Perform monthly checks of LED indicators to verify normal operation (green for power OK, amber for warnings). Clean the module’s cooling vents quarterly to prevent dust accumulation, which can affect thermal performance.

- Input Voltage Monitoring: Regularly measure input voltages to ensure they remain within the specified range (100–240 V AC). Fluctuations outside this range may indicate power source issues requiring investigation.

- Firmware Updates: Periodically update the module’s firmware via the Mark VIe system to incorporate performance improvements and bug fixes, following GE’s recommended procedures.

- Spare Parts Management: Store spare DS200PTBAG1BAA modules in a controlled environment (temperature: 20–25°C, humidity: <50%) to maintain functionality. Test spares annually to ensure readiness for replacement.

Product Guarantee

Our company provides a 12-month quality warranty for the GE DS200PTBAG1BAA, covering hardware defects under normal use. In the event of unexpected failures, we offer prompt replacement services to minimize downtime. For legacy or discontinued models like the DS200PTBAG1BAA, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation, troubleshooting, and system optimization, delivering tailored solutions to maintain your automation system’s reliability and efficiency.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE DS200DTBCG1A Control processor

GE DS200DTBDG1AAB Switch quantity input card

GE DS200DTBDGIABB Enhanced intelligent communication module

GE DS200EXDEG1A CPU module

GE DS200EXDEGIA Pulse input (PI) module

GE DS200FECBGIAAA Digital input module

GE DS200LRPBG1A Digital 24VDC output module

GE DS200NATOG2A Digital output module 24VDC

GE DS200NATOGIA Output module

GE DS200PANAH2A Output module

GE DS200PANAHIA High density main box

GE DS200PANAHIADS3820NGDB Remote extender module

GE DS200PCCAG5ACB Input pulse module

中文版

中文版