Product Overview: GE DS200PTBAG1AEC

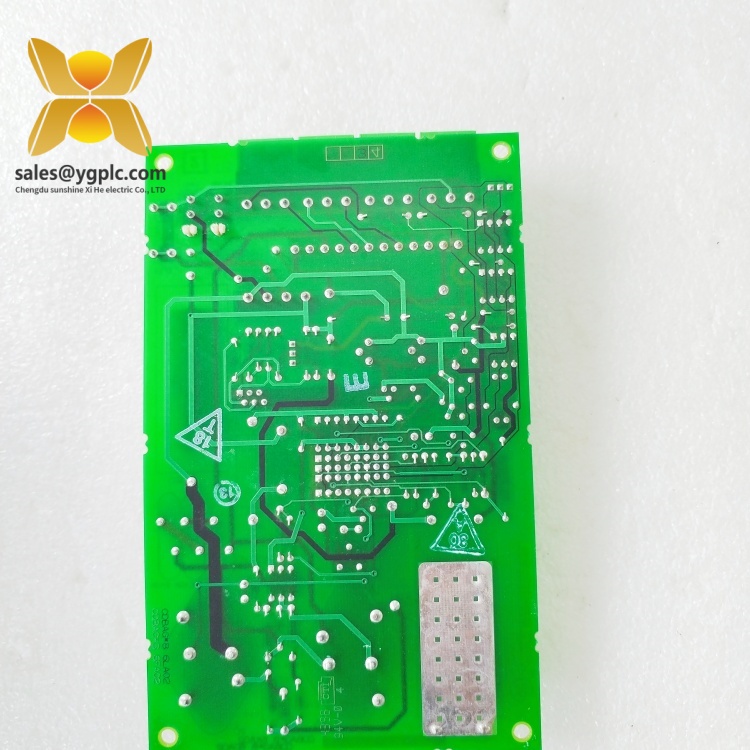

The GE DS200PTBAG1AEC is a high-performance termination board designed for the Speedtronic Mark V gas turbine control system, a cornerstone of industrial automation in power generation and heavy machinery applications. Manufactured by General Electric (GE), this module serves as a critical interface for signal termination, ensuring reliable connectivity between field devices and the control system. Its robust design and precise engineering make it an essential component for maintaining operational integrity in complex industrial environments.

The GE DS200PTBAG1AEC is a high-performance termination board designed for the Speedtronic Mark V gas turbine control system, a cornerstone of industrial automation in power generation and heavy machinery applications. Manufactured by General Electric (GE), this module serves as a critical interface for signal termination, ensuring reliable connectivity between field devices and the control system. Its robust design and precise engineering make it an essential component for maintaining operational integrity in complex industrial environments.

As part of the Mark V series, the GE DS200PTBAG1AEC is engineered to handle the demanding requirements of gas turbine control, including monitoring overspeed protection, flame detection, generator voltage/current signals, and synchronizing inputs. It features two terminal blocks with 72 signal wire terminals each, three 10-pin connectors (JJR, JJT, JJS), and six signal wire terminal posts, allowing for comprehensive connectivity with various sensors, actuators, and control modules. The board’s layout prioritizes ease of installation and maintenance, with clearly marked terminals and mounting holes in each corner for secure integration into the control panel.

In automation systems, the GE DS200PTBAG1AEC plays a pivotal role in centralizing signal distribution, reducing wiring complexity, and minimizing downtime. Its compatibility with the Mark V system ensures seamless integration with other modules like the TCEB (Turbine Control Electronic Board) and TCQE (Turbine Control Quad Element), enhancing overall system efficiency. By streamlining signal management, this termination board contributes to the stability and safety of gas turbine operations, particularly in power plants and industrial facilities where continuous uptime is critical.

Technical Specifications

| Parameter | Value |

|---|---|

| Manufacturer | General Electric (GE) |

| Product Type | Termination Board |

| Series | Speedtronic Mark V |

| Physical Dimensions | 3 inches (height) x 11.5 inches (width) |

| Weight | 0.8 kg |

| Place of Origin | USA |

| Terminal Blocks | 2 blocks, 72 terminals each |

| Connectors | 3 x 10-pin (JJR, JJT, JJS) |

| Signal Posts | 6 |

| Mounting Holes | 4 (one in each corner) |

| Working Temperature | -20°C to +60°C |

| Humidity Range | 5% to 95% (non-condensing) |

Main Features and Advantages

The GE DS200PTBAG1AEC stands out for its versatile connectivity and reliability in harsh industrial conditions. Its dual terminal blocks and multiple connectors enable the termination of a wide range of signals, including analog, digital, and high-voltage inputs, making it suitable for diverse applications within the Mark V system. The board’s design incorporates metal oxide varistors (MOVs) and capacitors to protect against voltage spikes and electromagnetic interference (EMI), ensuring signal integrity even in electrically noisy environments.

The GE DS200PTBAG1AEC stands out for its versatile connectivity and reliability in harsh industrial conditions. Its dual terminal blocks and multiple connectors enable the termination of a wide range of signals, including analog, digital, and high-voltage inputs, making it suitable for diverse applications within the Mark V system. The board’s design incorporates metal oxide varistors (MOVs) and capacitors to protect against voltage spikes and electromagnetic interference (EMI), ensuring signal integrity even in electrically noisy environments.

Another key advantage is its user-friendly installation process. The clearly labeled terminals and pre-drilled mounting holes simplify replacement, reducing downtime during maintenance. For instance, mapping signal wires to specific terminals (e.g., TB1 27 or TB2 70) ensures accurate reconnection, preventing errors that could disrupt turbine operations. Additionally, the board’s modular construction allows for easy integration with other Mark V modules, such as the DS200PTBAG1ABA protection termination module, enhancing system scalability.

The GE DS200PTBAG1AEC also supports redundant configurations, a critical feature in safety-critical systems like gas turbines. By terminating signals for overspeed protection and flame detection, it contributes to the system’s fail-safe operation, minimizing the risk of catastrophic failures. Its compatibility with both single-channel (Simplex) and triple-redundant (TMR) Mark V systems further underscores its adaptability to different operational requirements.

Application Fields

The GE DS200PTBAG1AEC is primarily used in gas turbine control systems across industries such as power generation, oil and gas, and heavy manufacturing. In power plants, it facilitates the precise control of turbine speed, fuel supply, and generator synchronization, ensuring efficient energy production. For example, it terminates signals from overspeed magnetic pickups and flame detectors, which are essential for protecting the turbine from damage during abnormal conditions.

The GE DS200PTBAG1AEC is primarily used in gas turbine control systems across industries such as power generation, oil and gas, and heavy manufacturing. In power plants, it facilitates the precise control of turbine speed, fuel supply, and generator synchronization, ensuring efficient energy production. For example, it terminates signals from overspeed magnetic pickups and flame detectors, which are essential for protecting the turbine from damage during abnormal conditions.

In industrial automation, this termination board is integral to distributed control systems (DCS) and emergency shutdown (ESD) systems, where it manages inputs from sensors and outputs to actuators. Its role in synchronizing generator voltage and current signals is particularly vital in combined-cycle power plants, where seamless integration between turbines and generators is required for optimal performance.

The GE DS200PTBAG1AEC also finds applications in retrofit projects, where it replaces obsolete components in aging Mark V systems. Its backward compatibility with earlier revisions ensures that it can be integrated into existing infrastructure without requiring significant system overhauls, reducing upgrade costs and downtime.

Related Products

- GE DS200PTBAG1ABA: A protection termination module designed for the Mark V system, providing overspeed protection and flame detection signals. It shares similar connectivity features with the DS200PTBAG1AEC but includes additional hardware jumpers for alarm horn control.

- GE DS200CTBAG1AEC: A control termination board that interfaces with the Mark V system’s control modules, complementing the DS200PTBAG1AEC in signal distribution.

- GE DS200TBPAG1A: A communication module used for serial data transmission within the Mark V system, enhancing the DS200PTBAG1AEC’s connectivity capabilities.

- GE DS200EXPSG1ABB: An expansion module that extends the I/O capacity of the Mark V system, working alongside the DS200PTBAG1AEC to support additional field devices.

- GE DS200SDCCG1AEC: A system diagnostic module that monitors the health of the Mark V system, providing real-time feedback to the DS200PTBAG1AEC and other components.

Installation and Maintenance

Pre-installation preparations: Before installing the GE DS200PTBAG1AEC, ensure the power to the control system is disconnected. Verify the physical dimensions of the board (3” x 11.5”) and the mounting holes align with the existing rack. Map the signal wires from the old board to their respective terminals (e.g., TB1 27, TB2 70) using labels or a diagram to avoid misconnection. Clean the mounting area and inspect for any debris or damage that could affect performance.

Pre-installation preparations: Before installing the GE DS200PTBAG1AEC, ensure the power to the control system is disconnected. Verify the physical dimensions of the board (3” x 11.5”) and the mounting holes align with the existing rack. Map the signal wires from the old board to their respective terminals (e.g., TB1 27, TB2 70) using labels or a diagram to avoid misconnection. Clean the mounting area and inspect for any debris or damage that could affect performance.

Maintenance suggestions: Regularly inspect the GE DS200PTBAG1AEC for signs of physical wear, such as loose connections or corrosion. Clean the board using a static-free cloth to remove dust and ensure proper airflow. Check the integrity of the MOVs and capacitors for any signs of swelling or discoloration, which may indicate failure. During routine maintenance, verify that all signal wires are securely fastened and that the board’s jumpers (e.g., J1 for alarm horn control) are correctly set. For critical applications, consider implementing a predictive maintenance schedule to identify potential issues before they escalate.

Product Guarantee

Our company offers a one-year quality warranty for the GE DS200PTBAG1AEC, covering hardware malfunctions not caused by human error. During the warranty period, we will replace any defective product free of charge. For discontinued models or urgent requirements, our global supply chain network ensures rapid procurement of scarce spare parts, minimizing downtime and supporting continuous industrial operations. With 17 years of experience in industrial control distribution, we are committed to delivering reliable products and technical support to meet your automation needs.

Our company offers a one-year quality warranty for the GE DS200PTBAG1AEC, covering hardware malfunctions not caused by human error. During the warranty period, we will replace any defective product free of charge. For discontinued models or urgent requirements, our global supply chain network ensures rapid procurement of scarce spare parts, minimizing downtime and supporting continuous industrial operations. With 17 years of experience in industrial control distribution, we are committed to delivering reliable products and technical support to meet your automation needs.

For inquiries, contact us via WhatsApp: +86 18859254943 or email: sales@ygdcs.com.

GE DS200PANAHIA probe

GE DS200PANAHIADS3820NGDB Tachometer sensor

GE DS200QTBAG1ACB modbus card

GE DS200QTBAG1ADC Power strip

GE DS200SDCCG1AHD Power source

GE DS200SDCCG4AFD base

GE DS200SDCCG4AGD exchange

GE DS200SDCCG5A DI module

GE DS200SDCCGIAGD AI card

GE DS200SHVG1BGD Pulse encoder

GE DS200SHVIG1BHD Module connector

GE DS200SHVMGIA Servo module

GE DS200SLCCG1ABB Control cabinet node unit

中文版

中文版