GE DS200PTBAG1ADC Terminal Block Module

Product Overview

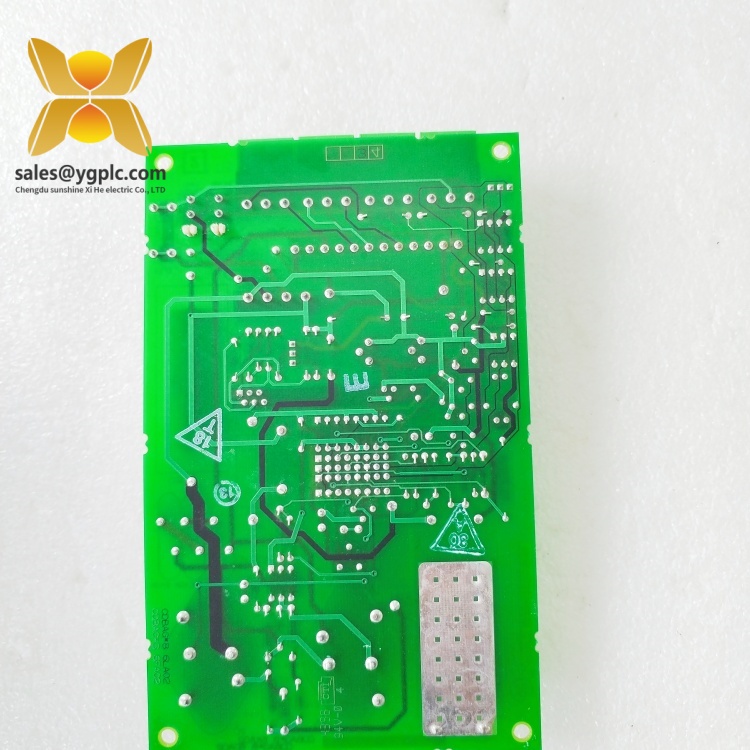

The GE DS200PTBAG1ADC is a high-reliability Terminal Block Module designed as a critical connectivity component for GE’s Mark VIe distributed control system (DCS), catering to industrial automation and machinery protection applications. As part of the DS200 Series, this module serves as the interface between field devices (e.g., sensors, actuators) and the Mark VIe control platform, enabling secure and flexible wiring in power generation, oil & gas, and manufacturing environments. The DS200PTBAG1ADC simplifies signal routing by providing a centralized terminal block for analog and digital signals, ensuring seamless integration with other Mark VIe modules such as controllers, I/O cards, and communication gateways.

Engineered for rugged industrial use, the GE DS200PTBAG1ADC features a modular design with removable terminal blocks, facilitating easy installation and maintenance. It supports a wide range of signal types, including 4–20 mA current loops, 0–10 V DC voltages, and discrete signals, with built-in surge protection to withstand transient voltage spikes. The module’s corrosion-resistant enclosure and conformal-coated circuitry ensure reliable performance in harsh environments, including high humidity, dust, and electromagnetic interference (EMI). By optimizing cable management and reducing wiring complexity, the DS200PTBAG1ADC enhances system scalability and minimizes the risk of installation errors in mission-critical applications.

In automation ecosystems, the DS200PTBAG1ADC plays a pivotal role in reducing downtime by enabling hot-swappable terminal block replacement without powering down the system. Its compatibility with GE’s Proficy software suite allows for real-time diagnostics of wiring integrity, ensuring early detection of loose connections or signal anomalies. Whether deployed in standalone control panels or large-scale DCS setups, this module delivers consistent performance, making it an indispensable component for industries reliant on robust and maintainable control systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200PTBAG1ADC |

| Manufacturer | GE |

| Product Type | Terminal Block Module |

| Platform | Mark VIe |

| Terminal Type | Removable screw-down terminals (24 positions) |

| Signal Compatibility | Analog (4–20 mA, 0–10 V DC), digital (dry contacts) |

| Voltage Rating | 250 V AC/DC |

| Current Rating | 10 A per terminal |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.2 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted (compatible with Mark VIe enclosures) |

| EMC Compliance | IEC 61000-4-2/3/4, FCC Part 15 Subpart B |

Key Features and Advantages

Modular Terminal Design: The DS200PTBAG1ADC features removable terminal blocks that allow technicians to pre-wire connections offline, reducing installation time and minimizing errors. This modularity also simplifies replacement in case of damage, ensuring quick turnaround during maintenance.

Wide Signal Compatibility: Supporting both analog and digital signals, the module eliminates the need for separate terminal blocks for different signal types, streamlining cable management and reducing hardware costs. Its 10 A current rating and 250 V voltage handling make it suitable for most industrial field devices.

Rugged Industrial Construction: Built with a steel-reinforced enclosure and flame-retardant materials, the DS200PTBAG1ADC meets rigorous industry standards for shock (IEC 60068-2-27) and vibration (IEC 60068-2-6), ensuring durability in harsh environments like offshore platforms and power plant control rooms.

Hot-Swap Capability: The module’s design allows terminal blocks to be replaced while the system is operational, minimizing downtime in live environments. This feature is critical for 24/7 industrial operations where uninterrupted control is essential.

EMI/RFI Immunity: Shielded terminal blocks and grounding provisions reduce interference from external sources, ensuring stable signal transmission even in high-noise environments dominated by motors, drives, or high-voltage equipment.

Easy Integration with Mark VIe: Designed exclusively for GE’s Mark VIe system, the DS200PTBAG1ADC aligns with the platform’s mechanical and electrical specifications, ensuring seamless compatibility with other DS200 Series modules (e.g., I/O cards, controllers).

Application Areas

The GE DS200PTBAG1ADC is essential for industries requiring reliable field device connectivity and robust cable management:

- Power Generation: Used in steam turbine control systems to connect temperature transmitters, pressure sensors, and emergency shutdown (ESD) switches, ensuring precise signal transmission for safe and efficient operation.

- Oil & Gas: Deployed in refineries and pipeline compressor stations to interface with flow meters, valve positioners, and fire & gas detectors, supporting real-time process control and safety interlocks.

- Manufacturing: Integrates with conveyor systems, robotic arms, and quality control sensors in automotive and chemical plants, enabling centralized monitoring and control of production lines.

- Water/Wastewater Treatment: Connects level sensors, pumps, and actuators in treatment facilities, facilitating automated control of water flow and chemical dosing processes.

Specific applications include:

- Sensor Integration: Provides a secure connection point for RTDs, thermocouples, and analog transmitters, ensuring accurate data acquisition for process optimization.

- Actuator Control: Routes control signals from the DCS to valves, motors, and solenoids, forming closed-loop control systems for precise process regulation.

- Safety System Wiring: Supports the integration of ESD switches and interlock signals into safety instrumented systems (SIS), complying with IEC 61511 standards for fault tolerance.

Related Products

- DS200AAHAH2ADC (Analog Input Module): Works in tandem with the DS200PTBAG1ADC to process analog signals from field devices, providing 16-bit resolution and galvanic isolation.

- DS200DDAIG1A (Digital Output Module): Uses the DS200PTBAG1ADC to distribute discrete control signals to actuators, such as motor starters and valve solenoids.

- DS200TCTGG1A (Turbine Control Module): Integrates with the DS200PTBAG1ADC to receive speed and position feedback from turbines, enabling real-time control adjustments.

- DS200COMM (Communication Module): Utilizes the module’s terminal blocks to interface with Ethernet or Profibus devices, facilitating remote monitoring via SCADA systems.

- DS200PWR (Redundant Power Supply Module): Provides reliable power to the Mark VIe rack, ensuring stable operation of the DS200PTBAG1ADC and connected devices.

- DS200TBCH (Terminal Block Chassis): Expands the system’s wiring capacity by providing additional terminal blocks, compatible with the DS200PTBAG1ADC for large-scale I/O applications.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE DS200PTBAG1ADC, ensure the Mark VIe rack is grounded and powered off. Verify that the module’s terminal block configuration matches the signal types of connected devices (e.g., analog vs. digital). Use stranded or solid-core wires (14–22 AWG) with appropriate crimp terminals, and route cables separately from high-voltage lines to minimize EMI. Secure the module in the rack using the provided mounting brackets, ensuring proper alignment with adjacent modules for optimal airflow.

Before installing the GE DS200PTBAG1ADC, ensure the Mark VIe rack is grounded and powered off. Verify that the module’s terminal block configuration matches the signal types of connected devices (e.g., analog vs. digital). Use stranded or solid-core wires (14–22 AWG) with appropriate crimp terminals, and route cables separately from high-voltage lines to minimize EMI. Secure the module in the rack using the provided mounting brackets, ensuring proper alignment with adjacent modules for optimal airflow.

Maintenance Suggestions:

- Routine Inspections: Perform quarterly visual checks to ensure terminal screws are tight, cables are free of damage, and the enclosure is free of dust or debris. Use a multimeter to verify continuity and signal integrity for critical connections.

- Terminal Block Replacement: If a terminal block is damaged or corroded, replace it with a spare DS200PTBAG1ADC terminal block while the system is running, ensuring proper grounding and signal routing after replacement.

- System Calibration: Annually inspect wiring connections during routine system calibration to ensure no loose terminals affect signal accuracy. Document any changes or repairs for compliance records.

- Spare Parts Management: Store spare terminal blocks and modules in a dry, static-free environment to prevent corrosion. Test spares periodically to ensure functionality, especially for critical applications.

Product Guarantee

Our company provides a 12-month quality warranty for the GE DS200PTBAG1ADC, covering hardware defects under normal use. In the event of terminal block failure or enclosure damage, we offer prompt replacement services to minimize downtime. For discontinued models like the DS200PTBAG1ADC, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation guidance, wiring diagrams, and troubleshooting, ensuring your control system remains reliable and compliant with industry standards.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE DS200PTBAG1BAA driver

GE DS200PTBAGIBBA servo

GE DS200PTCTG1B Eddy current sensor

GE DS200PTCTG2B monitor

GE DS200QTBAG1ABB rack

GE DS200QTBAG1ACB Remote module

GE DS200QTBAG1ADC Main processor

GE DS200RTBAG4A Pulse input

GE DS200RTBAG5A Analog quantity

GE DS200SDCCG1AEC Digital quantity

GE DS200PTBAGIBBA servo

GE DS200PTCTG1B Eddy current sensor

GE DS200PTCTG2B monitor

GE DS200QTBAG1ABB rack

GE DS200QTBAG1ACB Remote module

GE DS200QTBAG1ADC Main processor

GE DS200RTBAG4A Pulse input

GE DS200RTBAG5A Analog quantity

GE DS200SDCCG1AEC Digital quantity

中文版

中文版