Product Overview

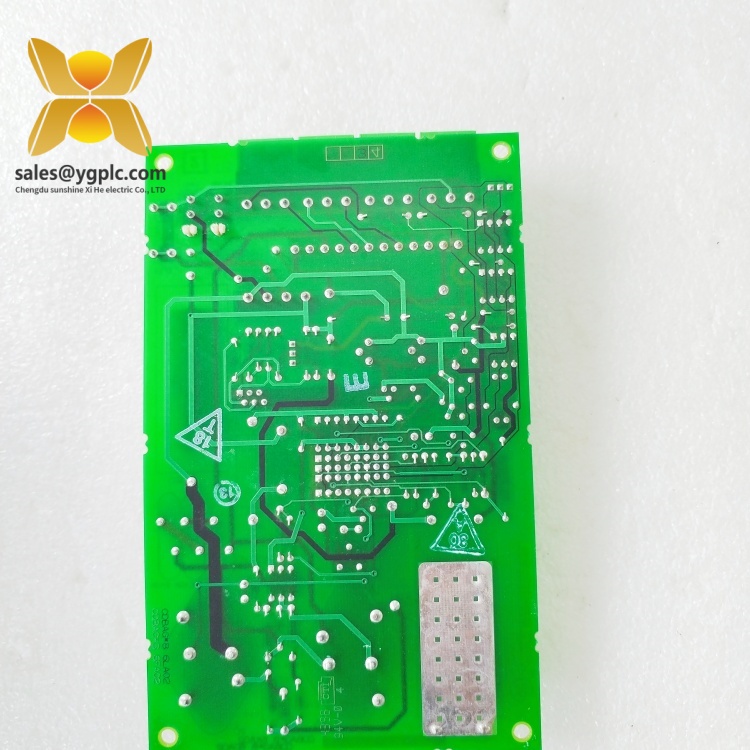

The GE DS200PCCAG6ADB is a high-performance Power Connect Board designed for critical applications within GE’s Mark V Turbine Control System. As a core component of this industry-leading platform, the GE DS200PCCAG6ADB ensures seamless power distribution and system integration in gas and steam turbine control environments. Manufactured by General Electric (GE), a trusted name in industrial automation, this module exemplifies precision engineering and reliability, making it an essential asset for power generation, oil and gas, and heavy industrial sectors.

The GE DS200PCCAG6ADB is a high-performance Power Connect Board designed for critical applications within GE’s Mark V Turbine Control System. As a core component of this industry-leading platform, the GE DS200PCCAG6ADB ensures seamless power distribution and system integration in gas and steam turbine control environments. Manufactured by General Electric (GE), a trusted name in industrial automation, this module exemplifies precision engineering and reliability, making it an essential asset for power generation, oil and gas, and heavy industrial sectors.

Functionally, the GE DS200PCCAG6ADB acts as a central hub for power management, facilitating efficient energy transfer between the turbine control system and auxiliary equipment. Its design emphasizes compatibility with GE’s Speedtronic Mark V architecture, enabling seamless integration with exciters, drives, and other system modules. By supporting redundant configurations, the board enhances system availability, a critical factor in high-stakes industrial operations where downtime is costly. The GE DS200PCCAG6ADB is engineered to withstand harsh industrial conditions, with a robust PCB coating that protects against moisture, dust, and electromagnetic interference. This durability, combined with its compact form factor, ensures consistent performance in demanding environments.

In automation systems, the GE DS200PCCAG6ADB plays a pivotal role in maintaining operational stability. It bridges the gap between control logic and power delivery, ensuring that commands from the turbine control system are executed with precision. By optimizing power distribution, the module contributes to reduced energy losses and improved overall system efficiency. Whether used in base-load power plants or dynamic industrial processes, the GE DS200PCCAG6ADB delivers the reliability and performance required to meet modern industrial demands. Its position as a key component in GE’s Mark V series underscores its role in driving innovation and sustainability across global industries.

Technical Specifications

| Parameter Name | Parameter Values |

|---|---|

| Manufacturer | General Electric (GE) |

| Product Type | Power Connect Board |

| Series | Mark V |

| Electrical Input | 24 V DC ±10% |

| Physical Dimensions | 10.5” (26.7 cm) x 6.2” (15.7 cm) x 1.5” (3.8 cm) |

| Weight | 2.2 lbs (1 kg) |

| Interface Type | Terminal block connections |

| Communication Protocol | Proprietary GE Mark V protocol |

| Working Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity Range | 5% to 95% non-condensing |

| Installation Method | Rack-mounted |

Main Features and Advantages

The GE DS200PCCAG6ADB stands out for its reliability and versatility, making it a preferred choice for mission-critical applications. Its redundant design ensures continuous operation even in the event of component failure, minimizing downtime and maximizing system uptime. The board’s compatibility with GE’s Mark V series allows for seamless integration with existing infrastructure, reducing the need for costly retrofits. Additionally, its high-power handling capabilities enable efficient management of electrical loads, ensuring stable performance across varying operational conditions.

The GE DS200PCCAG6ADB stands out for its reliability and versatility, making it a preferred choice for mission-critical applications. Its redundant design ensures continuous operation even in the event of component failure, minimizing downtime and maximizing system uptime. The board’s compatibility with GE’s Mark V series allows for seamless integration with existing infrastructure, reducing the need for costly retrofits. Additionally, its high-power handling capabilities enable efficient management of electrical loads, ensuring stable performance across varying operational conditions.

A key advantage of the GE DS200PCCAG6ADB is its rugged construction. The module’s durable PCB coating and robust housing protect against environmental stressors, ensuring longevity in harsh industrial settings. This resilience is further enhanced by its wide operating temperature range, making it suitable for both extreme cold and high-heat environments. The board’s user-friendly design simplifies installation and maintenance, with clearly labeled terminals and intuitive wiring configurations. This reduces setup time and lowers the risk of errors during integration.

Furthermore, the GE DS200PCCAG6ADB supports advanced diagnostics, allowing operators to monitor performance in real-time and identify potential issues before they escalate. This proactive approach to maintenance helps optimize system efficiency and extend component lifespan. By combining cutting-edge technology with GE’s decades of industry expertise, the GE DS200PCCAG6ADB delivers a cost-effective solution that balances performance, reliability, and ease of use.

Application Fields

The GE DS200PCCAG6ADB is widely used in power generation, oil and gas, and heavy industrial sectors where precision turbine control is essential. In power plants, it plays a critical role in managing power distribution for gas and steam turbines, ensuring efficient energy production and grid stability. Its ability to handle high electrical loads makes it ideal for applications requiring reliable power management, such as combined-cycle power plants and cogeneration systems.

The GE DS200PCCAG6ADB is widely used in power generation, oil and gas, and heavy industrial sectors where precision turbine control is essential. In power plants, it plays a critical role in managing power distribution for gas and steam turbines, ensuring efficient energy production and grid stability. Its ability to handle high electrical loads makes it ideal for applications requiring reliable power management, such as combined-cycle power plants and cogeneration systems.

In the oil and gas industry, the GE DS200PCCAG6ADB is deployed in offshore platforms and refineries to control turbine-driven compressors and pumps. Its rugged design ensures consistent performance in corrosive and high-vibration environments, supporting continuous operations in remote locations. The module’s compatibility with GE’s Speedtronic Mark V system also enables seamless integration with other critical components, such as exciters and drives, enhancing overall system efficiency.

Heavy industrial applications, including mining and manufacturing, benefit from the GE DS200PCCAG6ADB’s ability to manage power in high-demand processes. Whether used in large-scale machinery or conveyor systems, the module ensures stable power delivery, reducing wear and tear on equipment and improving operational safety. Its diagnostic capabilities also enable predictive maintenance, helping industries minimize downtime and optimize resource allocation.

Related Products

- GE DS200PCCAG1A: A predecessor model in the Mark V series, offering similar functionality but with earlier revisions.

- GE DS200PCCAG2A: An upgraded version with enhanced power handling capabilities, suitable for high-load applications.

- GE DS200PCCAG5A: Designed for specific turbine control configurations, providing tailored power distribution solutions.

- GE DS200PCCAG7A: A compact variant ideal for space-constrained environments, maintaining full compatibility with Mark V systems.

- GE DS200PCCAG9A: Features advanced diagnostic tools for real-time performance monitoring, enhancing predictive maintenance capabilities.

- GE DS200CVMAG1ADB: A voltage monitor board used in conjunction with the GE DS200PCCAG6ADB to ensure stable power supply.

- GE DS200CTBAG1A: A terminal board that interfaces with the GE DS200PCCAG6ADB for signal distribution.

- GE DS200DCPAG1A: A control processor board that works alongside the GE DS200PCCAG6ADB to manage system logic.

- GE DS200FCGDH1A: A drive control board designed for integration with the GE DS200PCCAG6ADB in high-power applications.

- GE DS200SBCAG1A: A static brake card that complements the GE DS200PCCAG6ADB in turbine stop systems.

Installation and Maintenance

Pre-installation preparations: Before installing the GE DS200PCCAG6ADB, ensure the system is powered off and all electrical connections are disconnected. Verify compatibility with the existing Mark V system architecture, including voltage requirements and physical mounting dimensions. Clean the installation area to prevent dust or debris from interfering with the module’s performance. Use anti-static equipment to handle the board and avoid electrostatic discharge (ESD) damage.

Pre-installation preparations: Before installing the GE DS200PCCAG6ADB, ensure the system is powered off and all electrical connections are disconnected. Verify compatibility with the existing Mark V system architecture, including voltage requirements and physical mounting dimensions. Clean the installation area to prevent dust or debris from interfering with the module’s performance. Use anti-static equipment to handle the board and avoid electrostatic discharge (ESD) damage.

Maintenance suggestions: Regularly inspect the GE DS200PCCAG6ADB for signs of physical damage, such as corrosion or loose connections. Clean the board using a dry, lint-free cloth to remove dust buildup. Check terminal connections for tightness and ensure all cables are securely fastened. Monitor the module’s operational temperature and humidity levels to ensure they remain within specified ranges. For software-related issues, consult GE’s official documentation or contact technical support for firmware updates and troubleshooting guidance.

Product Guarantee

Our company, a leading industrial control solutions provider with 17 years of expertise, offers a one-year quality warranty for the GE DS200PCCAG6ADB. This warranty covers hardware malfunctions unrelated to misuse or improper installation. In the event of a defect, we will promptly replace the module to minimize downtime. For discontinued models or urgent requirements, our global supply chain network ensures rapid availability of scarce spare parts, supporting continuous industrial operations.

Our company, a leading industrial control solutions provider with 17 years of expertise, offers a one-year quality warranty for the GE DS200PCCAG6ADB. This warranty covers hardware malfunctions unrelated to misuse or improper installation. In the event of a defect, we will promptly replace the module to minimize downtime. For discontinued models or urgent requirements, our global supply chain network ensures rapid availability of scarce spare parts, supporting continuous industrial operations.

We pride ourselves on delivering reliable after-sales service, including technical support and diagnostic assistance. Our team of experts is available to address inquiries and provide guidance on installation, maintenance, and system integration. By choosing our company, you gain access to a trusted partner committed to ensuring the longevity and performance of your industrial automation systems.

Contact Information

- WhatsApp: +86 18859254943

- E-mail: sales@ygplc.com

Note: All technical specifications and product details are based on available data. For precise information, refer to GE’s official documentation or contact our support team.

GE DS200SLCCG3AEE Eddy current sensor

GE DS200SLCCG3AEF monitor

GE DS200SLCCG3AFG System

GE DS200SLCCG3AGH DCS

GE DS200SLCCGIAEF rack

GE DS200STCAG1A Remote module

GE DS200TBCAG1AAB Main processor

GE DS200TBCBGIAAA Pulse input

GE DS200TBOFG1A Analog quantity

GE DS200TBPAG1A Digital quantity

GE DS200TBQAG1A Connection base plate

GE DS200TBQBG1ABB redundancy

GE DS200TBQBGIACB Network communication

中文版

中文版