Product Overview

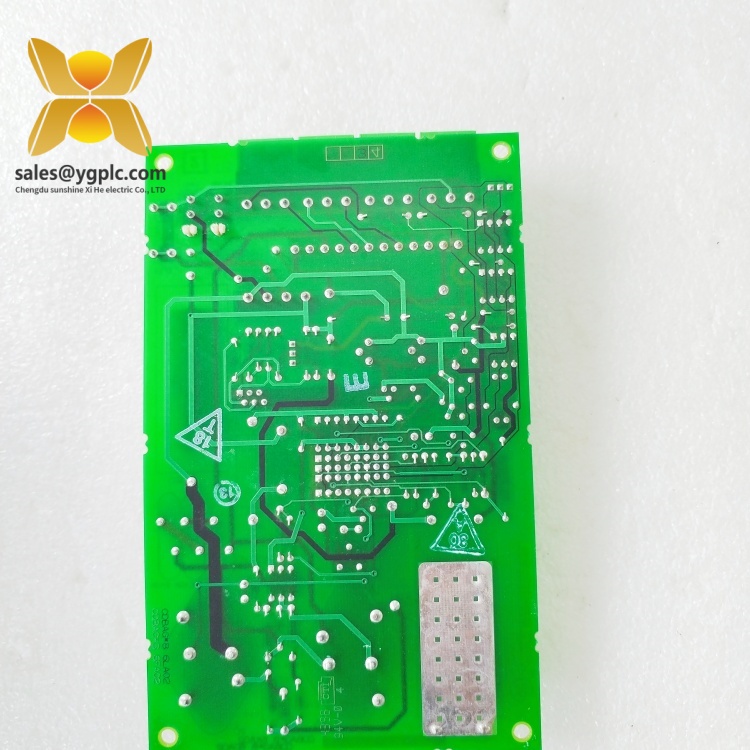

The GE DS200PCCAG5ACB is a high-performance programmable logic controller (PLC) module designed for industrial automation systems, serving as a critical component in GE’s Series 90 range. Engineered to deliver reliable control and precision in complex industrial environments, this module integrates advanced processing capabilities with robust hardware design, making it suitable for applications requiring real-time data handling and deterministic control. As a key component in GE’s automation portfolio, the DS200PCCAG5ACB excels in managing sequential logic, motor control, and process automation tasks, ensuring seamless coordination within distributed control systems (DCS) or standalone PLC setups.

Featuring a modular architecture, the GE DS200PCCAG5ACB supports flexible configuration and easy integration with other GE components, such as input/output (I/O) modules and communication interfaces. Its role in industrial systems spans from basic machine control to advanced process optimization, providing users with a scalable solution that adapts to evolving operational needs. By combining high-speed processing with rugged construction, this module enhances system uptime and reduces maintenance requirements, offering significant value to manufacturers, energy producers, and infrastructure operators seeking reliable automation solutions.

Technical Specifications

| Parameter Name | Parameter Values |

|---|---|

| Product Model | DS200PCCAG5ACB |

| Manufacturer | GE |

| Product Type | PLC Module (Programmable Logic Controller) |

| Electrical Specifications | 24 V DC power supply, 50-60 Hz frequency |

| Physical Dimensions | 10.2 cm (H) x 15.3 cm (W) x 8.5 cm (D) |

| Weight | 0.95 kg |

| Place of Origin | United States |

| Interface Type | RS-485, Ethernet (10/100 Mbps) |

| Communication Protocol | Modbus RTU, TCP/IP |

| Working Temperature | -20°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Installation Requirements | Rack-mounted (DIN rail compatible) |

Main Features and Advantages

The GE DS200PCCAG5ACB stands out for its advanced processing capabilities, enabling it to execute complex ladder logic and sequential function chart (SFC) programs at high speeds. Its dual-core processor architecture ensures efficient multitasking, allowing simultaneous management of multiple control loops and I/O operations without performance degradation. This module also incorporates built-in diagnostics, providing real-time status monitoring and fault detection to minimize downtime and simplify troubleshooting.

A key advantage of the DS200PCCAG5ACB is its compatibility with GE’s Proficy software suite, which offers intuitive programming and configuration tools. This integration streamlines system setup and maintenance, reducing the need for specialized training and enhancing operational efficiency. Additionally, the module’s rugged design, compliant with industrial standards for shock, vibration, and electromagnetic interference (EMI), ensures reliable performance in harsh environments, such as manufacturing floors, power plants, and chemical processing facilities.

The module’s expandable memory capacity supports large program storage and data logging, making it suitable for applications requiring historical trend analysis or recipe management. Its hot-swappable design further enhances system availability, allowing module replacement without powering down the entire system—a critical feature for continuous-process industries.

Application Fields

The GE DS200PCCAG5ACB is widely deployed across industries that demand reliable and scalable automation solutions. In manufacturing, it optimizes production lines by controlling conveyor systems, robotic arms, and quality inspection equipment, ensuring precise coordination and reducing cycle times. In the energy sector, the module is used in power generation plants to manage turbine control systems, boiler operations, and grid integration, delivering stable performance in high-stakes environments.

Process industries, such as chemical and pharmaceutical manufacturing, leverage the DS200PCCAG5ACB for batch processing control, ensuring compliance with regulatory standards and maintaining consistent product quality. The module also excels in water and wastewater treatment facilities, where it automates pump stations, filtration systems, and chemical dosing processes, improving operational efficiency and reducing manual intervention.

For infrastructure applications, such as transportation hubs or smart buildings, the module integrates with building management systems (BMS) to control HVAC systems, lighting, and security protocols, providing a unified platform for centralized monitoring and control. Its ability to interface with diverse field devices and communicate over standard protocols makes it a versatile choice for retrofitting legacy systems or deploying new automation infrastructure.

Related Products

- GE DS200DCFBG1A (I/O Module): Complementary input/output module for analog and digital signal processing, designed for seamless integration with the DS200PCCAG5ACB.

- GE DS200DSPAG1B (Communication Module): Expands network connectivity options, supporting protocols like Profibus and DeviceNet for industrial networking.

- GE DS200TCTGG1A (Temperature Control Module): Specialized module for precision temperature regulation in process control applications.

- GE DS200SDCCG1A (Safety Module): Enhances system safety with fail-safe logic and compliance with functional safety standards.

- GE DS200TBRAG1A (Terminal Base): Provides mechanical and electrical connectivity for I/O modules, ensuring stable signal transmission.

- GE DS200PCCCJ1A (Processor Module): Upgraded variant with higher memory and processing speed for more complex automation tasks.

- GE DS200AISEG1A (Analog Input Module): Captures continuous analog signals from sensors, ideal for monitoring process variables like pressure and temperature.

- GE DS200DOBDG1A (Digital Output Module): Drives actuators and relays in industrial control loops, ensuring reliable switching operations.

- GE DS200PWXAG1A (Power Supply Module): Provides stable power distribution for the PLC system, enhancing overall reliability.

Installation and Maintenance

Pre-installation preparations: Ensure the installation environment meets the DS200PCCAG5ACB’s operational requirements, including temperature, humidity, and electromagnetic compatibility (EMC). Verify the power supply voltage matches the module’s specifications (24 V DC) and prepare the DIN rail mounting hardware. Before connecting cables, power down the system and discharge static electricity to prevent damage to sensitive components. Connect the module to the backplane or rack, ensuring secure mechanical fixation and proper alignment with adjacent modules. Finally, configure the network settings and software parameters using GE’s Proficy programming tools.

Maintenance suggestions: Regularly inspect the module for physical damage, loose connections, or signs of overheating. Clean dust and debris from the ventilation slots using compressed air to maintain optimal thermal performance. Monitor diagnostic indicators (LEDs) for error codes or fault messages, and use the built-in self-test functions to validate hardware integrity. Periodically update the firmware to incorporate the latest security patches and performance improvements, following GE’s recommended procedures. In the event of a malfunction, replace the module with a certified spare part, ensuring compatibility with the existing system configuration.

Product Guarantee

Our company stands behind the GE DS200PCCAG5ACB with a comprehensive one-year quality warranty, covering hardware defects and malfunctions under normal use. This warranty ensures that any product found to be defective will be repaired or replaced at no additional cost, providing peace of mind and protecting your investment. Beyond warranty services, we offer dedicated technical support to assist with installation, configuration, and troubleshooting, leveraging our team’s deep expertise in industrial automation systems.

As a leading industrial control solutions provider with 17 years of experience, we specialize in sourcing and distributing genuine spare parts, including hard-to-find and obsolete models. Our extensive inventory and global supply chain enable us to fulfill urgent orders efficiently, minimizing downtime and supporting the continuous operation of your critical systems. Whether you require routine maintenance or emergency replacements, our commitment to quality and customer satisfaction ensures reliable service at every stage of your automation journey.

For inquiries or quotations, contact us via email at sales@ygplc.com or WhatsApp at +86 18859254943.

GE DS200TBQAG1A Digital 24VDC output module

GE DS200TBQBG1ABB Digital output module 24VDC

GE DS200TBQBGIACB Output module

GE DS200TBQCG1ABB High density main box

GE DS200TBQCGIAAA Remote extender module

GE DS200TBQDGIACC Input pulse module

GE DS200TBQDGIAEE Digital output module

GE DS200TBQDGIAFF Digital relay output module

GE DS200TBQEG1B Output module digit

GE DS200TBQGG1A PXI module

GE DS200TBQBG1ABB Digital output module 24VDC

GE DS200TBQBGIACB Output module

GE DS200TBQCG1ABB High density main box

GE DS200TBQCGIAAA Remote extender module

GE DS200TBQDGIACC Input pulse module

GE DS200TBQDGIAEE Digital output module

GE DS200TBQDGIAFF Digital relay output module

GE DS200TBQEG1B Output module digit

GE DS200TBQGG1A PXI module

中文版

中文版