GE DS200CPCAG1ABB Mark VIe Processor Module

Product Overview

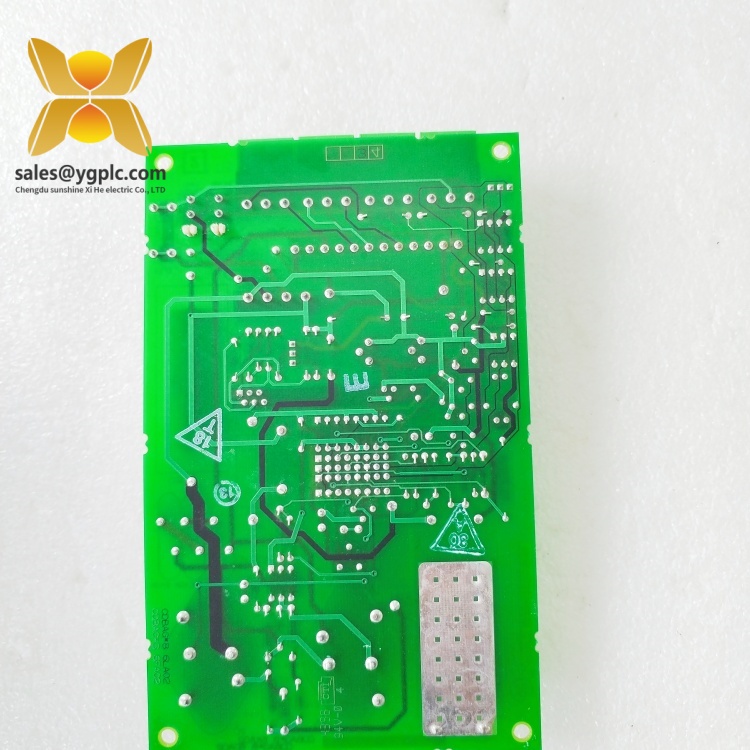

The GE DS200CPCAG1ABB is a high-performance Processor Module designed as the computational core of GE’s Mark VIe distributed control system (DCS), catering to mission-critical industrial automation applications in power generation, oil & gas, and heavy manufacturing. As a pivotal component of the DS200 Series, this module executes real-time control logic, manages data communication, and coordinates with I/O modules to ensure seamless operation of complex machinery such as steam turbines, gas compressors, and industrial boilers. The DS200CPCAG1ABB integrates advanced processing capabilities with rugged industrial design, making it indispensable for systems requiring high reliability and deterministic control.

Featuring a dual-core 32-bit RISC processor and 512 MB of operational memory, the GE DS200CPCAG1ABB delivers fast cycle times (down to 1 ms) for control algorithms, the ability to handle complex mathematical operations, and support for up to 10,000 I/O points. Its modular architecture allows flexible configuration for the needs of different applications, while the built-in redundant communication interface (Ethernet and Profibus DP) ensures reliable data exchange with human-machine interfaces (HMIs) and supervisory control and data acquisition (SCADA) systems. The module’s compatibility with GE’s Proficy Machine Edition software enables intuitive programming, diagnostics, and firmware updates, reducing engineering time and enhancing maintainability.

In automation ecosystems, the DS200CPCAG1ABB serves as the central nervous system of the Mark VIe platform, processing real-time data from analog and digital I/O modules to execute control strategies and safety interlocks. Its hot-swappable design allows for replacement without powering down the system, minimizing downtime during maintenance. By combining high computational power with fault-tolerant features, this module ensures continuous operation in harsh environments, including high temperatures, vibration, and electromagnetic interference, making it a cornerstone of reliable industrial control systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200CPCAG1ABB |

| Manufacturer | GE |

| Product Type | Processor Module |

| Platform | Mark VIe |

| Processor | Dual-core 32-bit RISC, 200 MHz |

| Memory | 512 MB RAM, 1 GB flash storage |

| Communication Interfaces | Ethernet (10/100 Mbps), Profibus DP, RS-485 |

| Input Voltage | 24 V DC ±10% |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 2.5 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted in Mark VIe enclosure |

| Certifications | CE, UL, IEC 61131-2 |

Key Features and Advantages

High-Speed Processing: The DS200CPCAG1ABB’s dual-core processor and optimized memory architecture enable rapid execution of control algorithms, supporting cycle times as low as 1 ms. This speed is critical for applications requiring real-time response, such as turbine speed control or emergency shutdown sequences.

Redundant Communication: Equipped with dual Ethernet and Profibus DP interfaces, the module supports redundant network configurations, ensuring uninterrupted data transmission even if one communication path fails. This redundancy enhances system reliability in mission-critical scenarios.

Modular and Hot-Swappable Design: The module’s plug-and-play design allows for easy installation and replacement while the system is running, reducing downtime during component upgrades or repairs. This feature is particularly valuable in 24/7 industrial operations where uninterrupted service is essential.

Comprehensive Diagnostics: Built-in self-diagnostic tools monitor processor health, memory usage, and communication integrity, providing real-time alerts via LED indicators and the Proficy software interface. These diagnostics help identify and resolve issues quickly, minimizing mean time to repair (MTTR).

Scalable System Integration: As part of the Mark VIe ecosystem, the DS200CPCAG1ABB seamlessly integrates with GE’s suite of I/O modules, communication gateways, and third-party systems via open protocols. This scalability allows for easy expansion of control systems as process requirements evolve.

Rugged Industrial Construction: The module’s metal enclosure and conformal-coated circuitry are designed to withstand extreme environmental conditions, including vibration (up to 5 g), shock (30 g), and humidity (5–95% non-condensing), ensuring reliable performance in harsh industrial settings.

Application Areas

The GE DS200CPCAG1ABB is widely deployed in industries where precise and reliable control of complex machinery is non-negotiable:

- Power Generation: Controls steam and gas turbines in thermal, hydro, and combined cycle power plants, managing speed, load, and fuel flow to optimize energy production and grid stability.

- Oil & Gas: Manages compression systems, pipeline valves, and refinery processes, ensuring safe and efficient operation in upstream, midstream, and downstream applications.

- Industrial Manufacturing: Oversees large-scale machinery in automotive, chemical, and pulp & paper facilities, such as extruders, mixers, and conveyor systems, to maintain production consistency and reduce mechanical wear.

- Water/Wastewater Treatment: Controls pumps, filters, and treatment processes, ensuring compliance with environmental standards and optimizing resource utilization.

Specific applications include:

- Turbine Control: Executes speed governing and load sharing algorithms to maintain stable operation of generators during fluctuating electrical demand.

- Safety Instrumented Systems (SIS): Processes safety-related signals from sensors and triggers shutdowns or alarms in response to critical faults, such as overpressure or temperature excursions.

- Process Automation: Coordinates multi-stage manufacturing processes, such as batch chemical reactions or continuous material handling, by integrating data from multiple I/O modules and adjusting control parameters in real time.

Related Products

- DS200AAHAH2ADC (Analog Input Module): Works alongside the DS200CPCAG1ABB to convert analog signals from sensors into digital data for processing, supporting applications like temperature and pressure monitoring.

- DS200AASA (Analog Output Module): Sends control signals from the processor to actuators, enabling closed-loop control of valves and motors in industrial processes.

- DS200DPRAG1A (Digital Input/Output Module): Provides discrete signal management for switches, relays, and contactors, expanding the DS200CPCAG1ABB’s capability to handle binary control logic.

- DS200COMM (Communication Module): Enhances the processor’s connectivity by enabling Ethernet/IP or Modbus TCP communication with SCADA systems, facilitating remote monitoring and control.

- DS200PWR (Redundant Power Supply Module): Ensures uninterrupted power to the Mark VIe rack, complementing the DS200CPCAG1ABB with reliable energy supply during voltage fluctuations.

- DS200TCTGG1A (Turbine Control Module): Specialized module for turbine-specific control algorithms, integrating with the DS200CPCAG1ABB to manage complex shaft dynamics and vibration analysis.

- DS200TBCH (Terminal Block Module): Simplifies field wiring by providing a centralized connection point for I/O signals, reducing installation complexity and improving cable management.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE DS200CPCAG1ABB, ensure the Mark VIe control rack is properly grounded and ventilated. Verify the power supply (24 V DC) and install redundant power modules for reliability. Use GE’s Proficy software to configure the module’s IP address, communication protocols, and control logic. Mount the module in the rack using the provided hardware, ensuring secure connections to the backplane and proper alignment with adjacent modules. Route communication cables separately from power cables to minimize electromagnetic interference.

Before installing the GE DS200CPCAG1ABB, ensure the Mark VIe control rack is properly grounded and ventilated. Verify the power supply (24 V DC) and install redundant power modules for reliability. Use GE’s Proficy software to configure the module’s IP address, communication protocols, and control logic. Mount the module in the rack using the provided hardware, ensuring secure connections to the backplane and proper alignment with adjacent modules. Route communication cables separately from power cables to minimize electromagnetic interference.

Maintenance Suggestions:

- Routine Inspections: Conduct monthly checks to monitor the module’s LED status indicators (e.g., power, communication, and fault lights) and ensure all connections are secure. Use Proficy software to review processor load and memory usage, addressing any anomalies promptly.

- Firmware Updates: Periodically update the module’s firmware to incorporate the latest features, security patches, and performance improvements, following GE’s step-by-step guidelines to avoid configuration errors.

- Redundancy Testing: Perform quarterly tests of redundant communication paths and power supplies to ensure failover functionality operates correctly. Document test results for compliance and maintenance records.

- Spare Parts Management: Store spare DS200CPCAG1ABB modules in a static-free, temperature-controlled environment (20–25°C, <50% humidity) to preserve component integrity. Test spares annually to ensure functionality, particularly for critical applications where rapid replacement is essential.

Product Guarantee

Our company provides a 12-month quality warranty for the GE DS200CPCAG1ABB, covering hardware defects under normal operating conditions. In the event of unexpected failures, such as processor malfunctions or communication errors, we offer prompt replacement services to minimize downtime. For legacy or discontinued models like the DS200CPCAG1ABB, our global supply chain network specializes in sourcing rare industrial control components, ensuring quick delivery for urgent needs. Our technical support team is available 24/7 to assist with installation, troubleshooting, and software configuration, delivering tailored solutions to maintain your system’s performance and reliability.

For sales inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE DS200NATOGIA Relay output

GE DS200PANAH2A Optical isolation module

GE DS200PANAHIA transformer

GE DS200PANAHIADS3820NGDB Digital output module

GE DS200PCCAG5ACB Control system power supply

GE DS200PCCAG6A Pressure transmitter

GE DS200PCCAG6ADB Main frame

GE DS200PTBAG1ADC Expansion rack

GE DS200PTBAG1AEC Network communication module

GE DS200PTBAG1BAA DCS spare parts

GE DS200PTBAGIBBA PLC central processing unit

GE DS200PTCTG1B DO module

GE DS200PTCTG2B Control processor

GE DS200QTBAG1ABB Switch quantity input card

GE DS200QTBAG1ACB Enhanced intelligent communication module

GE DS200QTBAG1ADC CPU module

GE DS200RTBAG4A Pulse input (PI) module

中文版

中文版