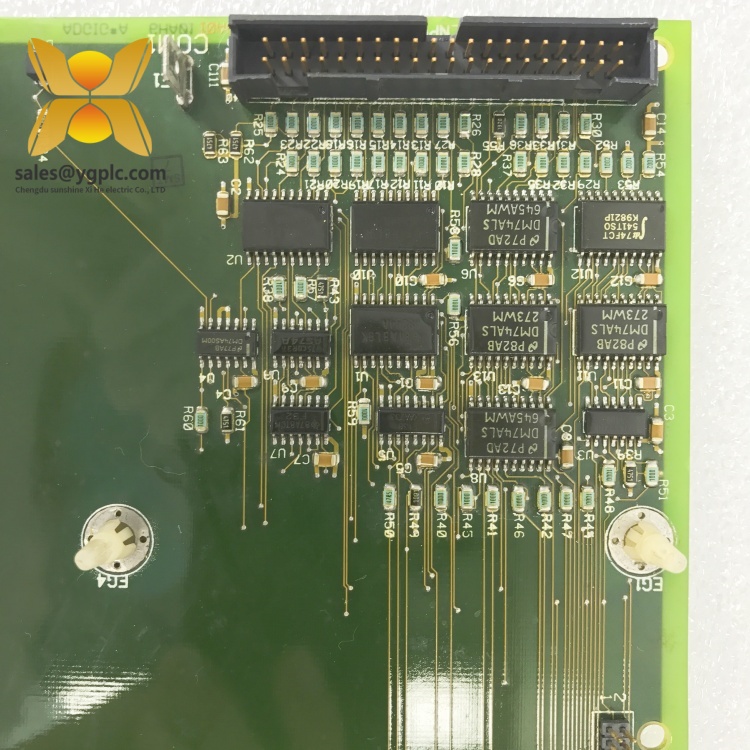

GE DS200ACNAGIACC Mark VIe Digital Input/Output Module

Product Overview

The GE DS200ACNAGIACC is a high-performance Digital Input/Output (DI/DO) Module designed for GE’s Mark VIe distributed control system (DCS), serving as a critical interface between industrial control systems and field devices. Engineered to manage discrete signals (e.g., switches, relays, and actuators), this module enables real-time monitoring and control in mission-critical applications across power generation, oil & gas, and manufacturing sectors. As part of the DS200 Series, the DS200ACNAGIACC ensures reliable signal transmission and fault-free operation in harsh industrial environments, where precision and durability are non-negotiable.

Featuring a robust design, the GE DS200ACNAGIACC supports multiple digital input/output channels with galvanic isolation, protecting the control system from voltage surges and electromagnetic interference (EMI). Its hot-swappable architecture allows for module replacement without powering down the system, minimizing downtime during maintenance. The module’s compatibility with GE’s Proficy software suite enables seamless configuration, diagnostics, and integration with higher-level SCADA systems, enhancing operational efficiency and reducing engineering complexity.

In automation ecosystems, the DS200ACNAGIACC acts as a bridge between the Mark VIe controller and field devices, converting binary signals (e.g., ON/OFF states) into digital data for processing and sending control commands to actuators. Its dual-channel design supports redundant operation, ensuring system resilience in critical applications such as turbine trip systems, emergency shutdown (ESD) logic, and conveyor control. By delivering reliable discrete signal management, this module optimizes process safety, reduces unplanned outages, and extends the lifecycle of industrial equipment.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200ACNAGIACC |

| Manufacturer | GE |

| Product Type | Digital Input/Output Module |

| Platform | Mark VIe |

| Input Channels | 16 isolated digital inputs (24 V DC) |

| Output Channels | 16 isolated digital outputs (24 V DC, 0.5 A sink/source) |

| Isolation | 500 V RMS galvanic isolation per channel |

| Switching Speed | ≤10 ms |

| Power Supply | 24 V DC ±10% (from Mark VIe rack) |

| Physical Dimensions | 228.6 mm (H) × 177.8 mm (W) × 76.2 mm (D) |

| Weight | 1.5 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting | Rack-mounted in Mark VIe enclosure |

| Communication | Proprietary Mark VIe bus |

Key Features and Advantages

Dual-Functionality Design: The DS200ACNAGIACC integrates both digital input and output channels, simplifying system architecture by combining signal acquisition and control in a single module. This dual functionality reduces hardware complexity and cabling requirements, lowering installation and maintenance costs.

Galvanic Isolation and Noise Immunity: Each channel features 500 V RMS galvanic isolation, preventing ground loops and protecting the control system from transient voltage spikes. Advanced filtering ensures reliable signal integrity in high-noise environments, such as those with motor drives or power transformers.

Hot-Swap Capability: The module’s plug-and-play design allows for safe replacement while the system is operational, enabling maintenance without disrupting ongoing processes. This feature is critical for 24/7 industrial operations where downtime must be minimized.

Redundant Signal Processing: With dual-channel redundancy, the DS200ACNAGIACC ensures continuous operation even if one channel fails. This design meets the highest reliability standards, making it suitable for safety instrumented systems (SIS) compliant with IEC 61508 and IEC 61511.

Wide Operating Range: Built to withstand extreme temperatures, vibration, and humidity, the module complies with industrial standards (e.g., IEC 60068-2-6 for vibration), ensuring performance in harsh environments like offshore platforms, refineries, and power plant control rooms.

User-Friendly Configuration: Compatible with GE’s Proficy software, the module allows engineers to configure input/output states, set debounce timers, and monitor channel health via a intuitive interface. Real-time diagnostics provide instant feedback on signal status, reducing troubleshooting time.

Application Areas

The GE DS200ACNAGIACC is widely deployed in industries requiring reliable discrete signal control and monitoring:

- Power Generation: Manages turbine trip signals, generator breaker states, and auxiliary system controls in thermal, hydro, and nuclear power plants. For example, it interfaces with emergency stop switches to trigger shutdowns during critical faults.

- Oil & Gas: Controls valve positions, pump starters, and safety interlocks in refineries, pipelines, and offshore platforms. It supports ESD systems by monitoring pressure switches and activating shutdown sequences when thresholds are exceeded.

- Manufacturing: Optimizes production lines by controlling conveyor belts, robotic arms, and packaging machinery. The module’s fast switching speed (≤10 ms) ensures precise coordination in high-speed assembly processes.

- Water/Wastewater Treatment: Monitors level switches and flow meters, sending commands to pumps and valves to maintain optimal process conditions. Its rugged design withstands moisture and corrosive environments in treatment facilities.

Specific applications include:

- Machine Safety Systems: Integrates with light curtains and safety mats in manufacturing equipment, ensuring compliance with OSHA and ISO 13849 standards.

- Process Automation: Controls motor starters and variable frequency drives (VFDs) in chemical plants, enabling automated batch processes and reducing manual intervention.

- Grid Substation Control: Monitors circuit breaker status and sends trip signals in power distribution systems, enhancing grid stability and fault response times.

Related Products

- DS200AADA (Digital Input Module): A single-function DI module with 16 channels, ideal for applications requiring only signal acquisition.

- DS200AASA (Digital Output Module): Complementary DO module with 16 channels, designed for the Mark VIe system to expand output capabilities.

- DS200COMM (Communication Module): Enables Ethernet connectivity for the DS200ACNAGIACC, allowing remote monitoring via SCADA systems.

- DS200PWR (Redundant Power Supply Module): Ensures uninterrupted operation by providing backup power to the Mark VIe rack, critical for the DS200ACNAGIACC in unstable power environments.

- DS200TBCH (Terminal Block Module): Simplifies field wiring with a centralized connection point for DI/DO signals, reducing installation errors.

- DS200TCTGG1A (Turbine Control Module): Works in tandem with the DS200ACNAGIACC to process discrete signals for turbine speed and load control.

- DS200ALG (Algorithm Module): Executes control logic based on DI/DO data, supporting advanced functions like interlock sequences and state machine operations.

Installation and Maintenance

Pre-installation Preparations:

Before installing the GE DS200ACNAGIACC, ensure the Mark VIe rack is grounded and ventilated. Verify that the module’s voltage settings match the field devices (e.g., 24 V DC for both inputs and outputs). Use shielded cables for signal wiring, routing them separately from high-voltage cables to avoid EMI. Secure the module in the rack using the provided hardware and connect power via the Mark VIe backplane. Configure channel parameters (e.g., input debounce time, output latch settings) using Proficy software, ensuring compatibility with the control system’s logic requirements.

Before installing the GE DS200ACNAGIACC, ensure the Mark VIe rack is grounded and ventilated. Verify that the module’s voltage settings match the field devices (e.g., 24 V DC for both inputs and outputs). Use shielded cables for signal wiring, routing them separately from high-voltage cables to avoid EMI. Secure the module in the rack using the provided hardware and connect power via the Mark VIe backplane. Configure channel parameters (e.g., input debounce time, output latch settings) using Proficy software, ensuring compatibility with the control system’s logic requirements.

Maintenance Suggestions:

- Routine Checks: Monthly inspections should include verifying LED status indicators (e.g., power, channel activity) and tightening terminal connections. Use Proficy to review channel diagnostics for signal anomalies, such as open circuits or shorted outputs.

- Functional Testing: Quarterly tests should involve simulating input signals (e.g., using a test switch) to ensure corresponding outputs activate correctly. Document test results to maintain compliance with safety standards.

- Firmware Updates: Periodically update the module’s firmware through the Mark VIe controller to access bug fixes and performance improvements, following GE’s step-by-step guidelines to prevent system disruptions.

- Spare Parts Management: Store spare DS200ACNAGIACC modules in a static-free environment with controlled temperature (20–25°C) and humidity (<50%). Test spares annually to ensure functionality, particularly for critical applications where immediate replacement is essential.

Product Guarantee

Our company provides a 12-month quality warranty for the GE DS200ACNAGIACC, covering hardware defects under normal use. In the event of module failure or signal irregularities, we offer prompt replacement services to minimize operational downtime. For discontinued models like the DS200ACNAGIACC, our global supply chain network specializes in sourcing rare and obsolete industrial control components, ensuring rapid delivery for urgent needs. Our technical support team is available 24/7 to assist with installation, troubleshooting, and software configuration, delivering reliable solutions to keep your automation systems running efficiently.

For inquiries, contact us via WhatsApp at +86 18859254943 or email at sales@ygplc.com.

GE DS200AAHAHIAD Eddy current sensor

GE DS200AAHAHIAED monitor

GE DS200ACNAGIACC System

GE DS200ACNAGIADD DCS

GE DS200CPCAG1ABB rack

GE DS200CPCAG1ABB Remote module

GE DS200CTBAG1ACC Main processor

GE DS200CTBAGIADD Pulse input

GE DS200DACAGIA Analog quantity

GE DS200DTBAG1A Digital quantity

GE DS200DTBBG1ABB Connection base plate

GE DS200DTBBGIAAA redundancy

中文版

中文版