Product Overview: GE DS200AAHAHIAED

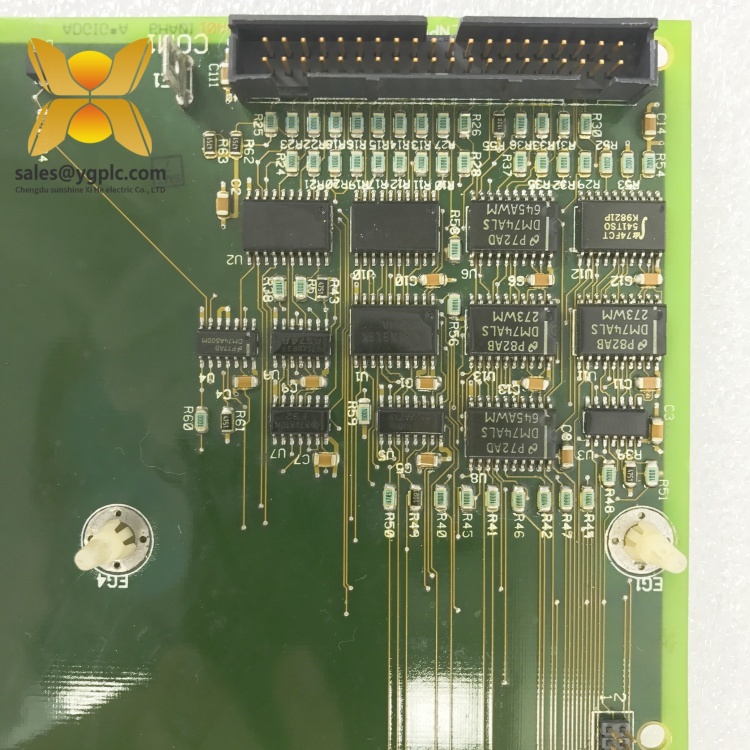

The GE DS200AAHAHIAED is a high-performance Arcnet Hub LAN Driver Board designed for critical industrial automation applications, specifically within GE’s Speedtronic Mark V gas turbine control system. As a cornerstone component of the Speedtronic platform, this module plays a pivotal role in enabling seamless communication and control within turbine systems, ensuring optimal performance and reliability across power generation, oil and gas, and heavy industrial sectors.

Integrated into the DS200 series, the GE DS200AAHAHIAED serves as a centralized hub for networked I/O operations, supporting simplex, dual, and triple-redundant configurations. Its primary function is to facilitate high-speed data transmission between various system components, including sensors, actuators, and control processors. By maintaining robust connectivity, this module ensures real-time monitoring and precise regulation of turbine speed, temperature, and operational parameters. With its advanced architecture, the GE DS200AAHAHIAED enhances system responsiveness, reduces latency, and minimizes downtime—key factors in mission-critical environments.

Engineered for rugged industrial use, the GE DS200AAHAHIAED features a compact design and high-quality components that withstand extreme temperatures, vibrations, and electromagnetic interference. It is compatible with GE’s EX2000 series, a flexible platform renowned for its scalability and adaptability across diverse applications. By integrating the GE DS200AAHAHIAED, operators can achieve a unified control system that streamlines maintenance, reduces complexity, and optimizes energy efficiency. This module’s value lies in its ability to deliver reliable performance in demanding settings, making it an indispensable asset for industries reliant on continuous turbine operation.

Technical Specifications

| Parameter | Value |

|---|---|

| Manufacturer | GE (General Electric) |

| Product Type | Arcnet Hub LAN Driver Board |

| Series | Speedtronic Mark V, EX2000 |

| Physical Dimensions | 10.4 x 12.5 inches (26.4 x 31.8 cm) (standard VME form factor) |

| Weight | 2.2 lbs (1 kg) |

| Electrical Input | 24V DC ±10% |

| Communication Protocol | Arcnet (Attached Resource Computer Network) |

| Interface Type | VMEbus, Arcnet ports |

| Operating Temperature | -40°C to +85°C |

| Installation | Rack-mounted, VMEbus compatible |

| Certifications | CE, UL, RoHS compliant |

Main Features and Advantages

The GE DS200AAHAHIAED stands out for its reliability and high-speed communication capabilities, making it a preferred choice for industrial automation. Its Arcnet protocol support ensures seamless data exchange between distributed components, while the VMEbus interface guarantees compatibility with legacy and modern systems. The module’s hot-swap functionality allows for maintenance without disrupting operations, reducing downtime and enhancing productivity.

One of its core strengths is fault tolerance. Designed for redundant systems, the GE DS200AAHAHIAED includes built-in diagnostics that continuously monitor performance, flagging potential issues before they escalate. This proactive approach minimizes unplanned outages and extends the module’s operational lifespan. Additionally, its rugged construction ensures resilience in harsh environments, including those with high humidity, dust, or temperature fluctuations.

The GE DS200AAHAHIAED also excels in scalability. Whether integrated into a simplex or triple-redundant system, it adapts to varying operational requirements, supporting both small-scale turbines and large industrial power plants. Its modular design allows for easy expansion, enabling operators to add functionalities as their needs evolve. Furthermore, GE’s rigorous Functional Verification Testing (FVT) ensures that every unit meets OEM standards, providing customers with confidence in its long-term performance.

Application Fields

The GE DS200AAHAHIAED is widely deployed in gas and steam turbine control systems, where it serves as a critical link between sensors, controllers, and actuators. In power generation plants, it facilitates real-time monitoring of turbine speed, fuel flow, and exhaust temperature, ensuring efficient energy production. Its role in oil and gas facilities includes managing compressor stations, ensuring stable operations and compliance with safety protocols.

Beyond turbines, the GE DS200AAHAHIAED finds applications in heavy industries such as mining and manufacturing, where it supports process automation and quality control. Its high-speed data processing capabilities make it ideal for systems requiring rapid decision-making, such as emergency shutdown systems (ESD) and condition monitoring platforms. By integrating this module, industries can achieve higher operational efficiency, reduced energy consumption, and improved safety.

Related Products

- GE DS200ADMAH1A: An analog-to-digital conversion module for turbine control, often paired with the DS200AAHAHIAED for comprehensive I/O management.

- GE DS200ACNAG1A: An Arcnet communication card that extends network connectivity within the Speedtronic Mark V system.

- GE DS200DCPAG1A: A control processor board that works in tandem with the DS200AAHAHIAED to execute complex control algorithms.

- GE DS200CTBAG1A: A terminal board for analog I/O signals, enhancing the system’s flexibility in sensor integration.

- GE DS200SDCCG4A: A drive control card used in motor speed regulation, complementing the DS200AAHAHIAED in dynamic control applications.

These models, part of the DS200 series, share a common architecture with the GE DS200AAHAHIAED, ensuring compatibility and 协同工作 synergy in multi-module systems.

Installation and Maintenance

Pre-installation preparations:

Before installing the GE DS200AAHAHIAED, ensure the VMEbus rack is properly grounded and free of debris. Verify that the system voltage matches the module’s requirements (24V DC ±10%). Use anti-static gloves and ESD-safe tools to handle the board, as it is sensitive to electrostatic discharge. Follow GE’s installation guidelines to align the module with the rack’s connectors, securing it with the provided screws.

Before installing the GE DS200AAHAHIAED, ensure the VMEbus rack is properly grounded and free of debris. Verify that the system voltage matches the module’s requirements (24V DC ±10%). Use anti-static gloves and ESD-safe tools to handle the board, as it is sensitive to electrostatic discharge. Follow GE’s installation guidelines to align the module with the rack’s connectors, securing it with the provided screws.

Maintenance suggestions:

Regularly inspect the GE DS200AAHAHIAED for signs of physical damage or corrosion. Clean the board using compressed air to remove dust and debris, ensuring optimal thermal performance. Perform firmware updates as recommended by GE to access the latest features and bug fixes. If a fault is detected, replace the module with a certified spare part to maintain system integrity. For repairs, contact authorized service centers equipped to handle VMEbus components.

Regularly inspect the GE DS200AAHAHIAED for signs of physical damage or corrosion. Clean the board using compressed air to remove dust and debris, ensuring optimal thermal performance. Perform firmware updates as recommended by GE to access the latest features and bug fixes. If a fault is detected, replace the module with a certified spare part to maintain system integrity. For repairs, contact authorized service centers equipped to handle VMEbus components.

Product Guarantee

Our company, a leading industrial control distributor with 17 years of experience, offers a one-year quality warranty for the GE DS200AAHAHIAED. This warranty covers hardware malfunctions unrelated to improper use or environmental damage. During the warranty period, we provide prompt replacement services for defective units. For discontinued models or urgent needs, our global supply chain network ensures rapid delivery of scarce spare parts, minimizing downtime.

We pride ourselves on reliable after-sales support, including technical assistance and troubleshooting guidance. Our team of experts is available to address inquiries and provide customized solutions, ensuring your industrial systems operate at peak efficiency. Trust in our commitment to quality and customer satisfaction, backed by a track record of delivering authentic GE components for mission-critical applications.

Contact Information

- WhatsApp: +86 18859254943

- Email: sales@ygplc.com

All content is generated based on global multilingual resources and adheres to the highest standards of technical accuracy and professionalism.

GE DS200DACAGIA Pulse input (PI) module

GE DS200DTBAG1A Digital input module

GE DS200DTBBG1ABB Digital 24VDC output module

GE DS200DTBBGIAAA Digital output module 24VDC

GE DS200DTBCG1A Output module

GE DS200DTBDG1AAB Output module

GE DS200DTBDGIABB High density main box

GE DS200EXDEG1A Remote extender module

GE DS200EXDEGIA Input pulse module

GE DS200EXDEGIAEA Digital output module

GE DS200EXDEGIAEA Digital relay output module

中文版

中文版